11. The back of the machine may now gently be

pulled away to gain access to the current trans-

ducer. Note: The rear of the machine cannot be

removed completely.

12. Carefully swing the rear of the machine open to

the left while facing the rear of the machine.

13. Perform the Snubber Board Removal

Procedure.

14. Remove leads #X2 and #20 from the output diode

module.

15. Remove leads #X4 and #40 from the other output

diode module.

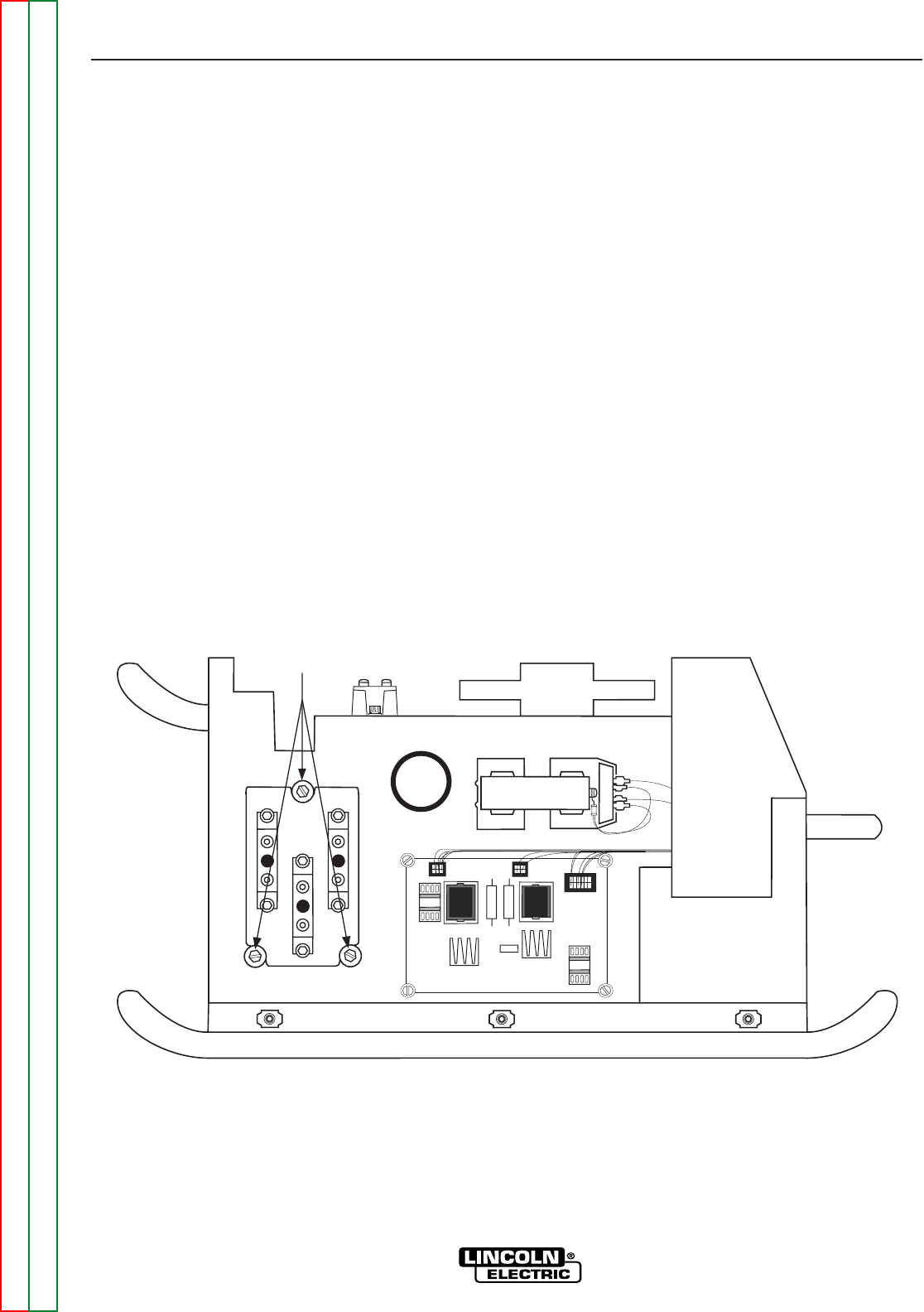

16. Using a 3/8” wrench, remove the three mounting

screws from the output diode heatsink assembly.

Take note placement of insulation for reassembly.

See Figure F.42.

17. Cut any necessary cable ties and carefully remove

the heavy lead from the diode heatsink using a

1/2” nut driver.

18. Remove the output diode heatsink assembly

through the rear of the machine.

19. Remove plug #J90 from the current transducer.

20. Using a 3/8” nut driver, remove the two mounting

nuts from the current transducer.

TROUBLESHOOTING & REPAIR

CURRENT TRANSDUCER REMOVAL AND REPLACEMENT (continued)

F-90 F-90

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

3/8"

MOUNTING

BOLTS

FIGURE F.42– OUTPUT HEATSINK MOUNTING SCREW LOCATION