ACCESSORIES

C-6 C-6

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

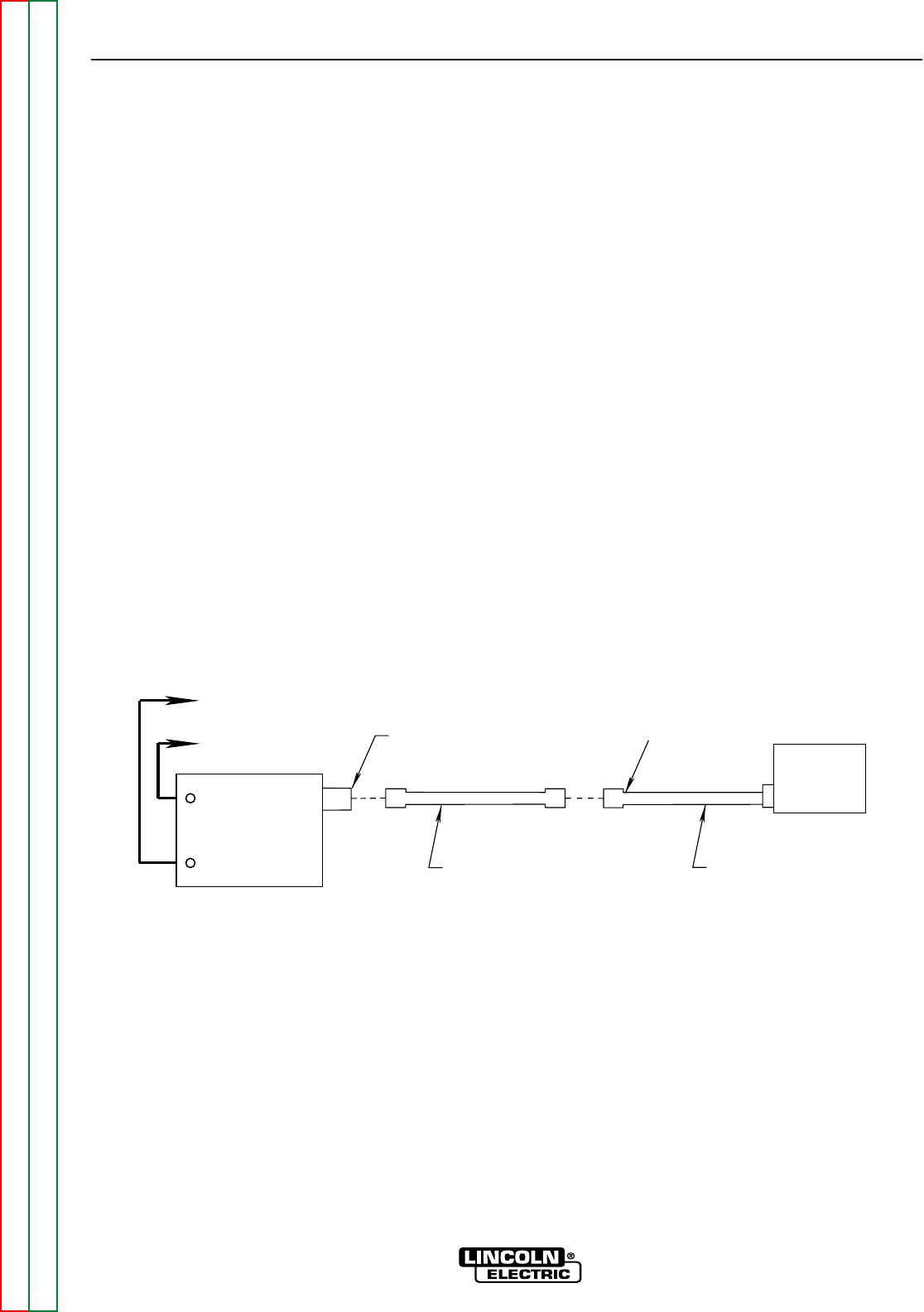

CONNECTION OF THE LN-25 WITH K431

REMOTE OPTION TO THE V350-PRO.

NOTE: AN LN-25 CAN ONLY BE USED WITH A FAC-

TORY OR “CE” VERSION OF THE V350-PRO.

1. Remove input power to the V350-PRO.

2. Connect the electrode cable to the output terminal

of polarity required by the electrode. Connect the

work lead to the other terminal. Welding cable

must be sized for current and duty cycle of the

application.

3. Attach the single lead from the LN-25 control box

to the work using the spring clip on the end of the

lead. This is only a control lead - it carries no

welding current.

4. Set the voltmeter switch to the electrode polarity

chosen.

5. Set “CONTROL SELECT” to “REMOTE”.

6. Set the “MODE” to the “CV-WIRE” position.

7. Set “WELD TERMINALS SELECT” to the

“REMOTE” position.

8. Set the “ARC CONTROL” to the “O” position and

then adjust to suit.

9. Connect the K432 remote control cable to the LN-

25.

10. Connect the K876 adapter to the K432 and to the

24/42VAC 14-pin amphenol located at the rear of

the V350-PRO.

11. Adjust the wire feed speed and voltage at the LN-

25.

NOTE: See Figure C.4 for connection Using K867

adapter.

TO

WORK

-

+

14 PIN (24/42VAC)

AMPHENOL

ELECTRODE CABLE

TO LN-25

K432 REMOTE

CONTROL CABLE

INVERTEC

POWER SOURCE

LN-25 WITH

K431 OPTION

6 PIN AMPHENOL

K876 ADAPTER

NOTE: Illustration shows electrode connected for positive polarity.

Figure C.3 LN-25 with K431 Remote Option to the V350-PRO