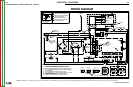

ElEcTrical DiaGramS

G-2

cOmpacT WirE WElDErS

WiriNG DiaGram - cOmplETE machiNE - (m20410)

N.C. CAVITY NUMBERING SEQUENCE VIEWED FROM INSERTION SIDE

OF CONNECTORS.

TO GROUND

PER NA

TI

ONAL

ELECTRICAL

CODE.

GUN

X1

X2

T1

TRANS-

FORMER

OUTPUT

CHOKE

N.A.

CAP-

LOCATED

I

N

T

RANSFORMER

CAP+

MOTOR

SPOOL GUN

(OPTIONAL)

THERMOSTAT

TMP

WIRE FEED MOTOR

MOT+

TS1

R1

10

9

8

7

6

5

4

3

21

FAN

4

3

2

1

LATCH

GAS

SOLENOID

SOL

CB1

CAPACITOR

N.B. WORK AND GUN CONNECTIONS SHOWN FOR GMAW WELDING.

ELECTRICAL SYMBOLS PER E1537

COMPOUND (DOW CORNING 340) WHEN REATTACHING.

N.A. BOLTED ALUMINUM CONNECTIONS REQUIRE T12837 JOINT

NOTES:

D1

N.A.

FAN

FAN

WORK

C1

N.A.

E

IT

HER

M20

410

FAN

SOL

RIBBED OR

STRIPED LEAD

SMOOTH

LEAD

N.B.

MOT-

TMP

CAP-

CAP+

SOL

MOT+

MOT-

SOL

TMP

H2

H1

6

FAN

TS2

H1

H2

X1

X2

1

GND

GND

5

S1

6

1

432

1

P6

J6

544A

543A

4A

2A

TMP

6

5

4

3

21

543A

2A

544A

4A

N.D. J4 IS DETERMINED BY MACHINE'S INPUT VOLTAGE.

SEE

I

DEN

TI

TY PLUG

CON

FI

GURA

TI

ON

DETAIL BELOW

N.D.

N.E. THIS COMPONENT IS "S1" FOR TAPPED MACHINES AND "R2" FOR

CONTINUOUS MACHINES.

N.E.

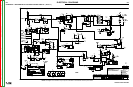

WIRING DIAGRAM

P5 N.C.

10

P3 N.C.

9876

5

4321

654

321

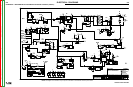

IDENTITY PLUG CONFIGURATION

230V120V

J4

1

2

3

4

J4

1

2

3

4

Do not touch electrically live parts

Disconnect input power by unplugging

power cord before servicing.

Do not operate with covers removed.

Only qualified persons should install,

use or service this machine.

can kill

HIGH VOLTAGE

WARNING

N.F. SEE S26766 FOR SPOT TIMER KIT WIRING DIAGRAM.

N

.F

.

N.G. SEE M20410-1 FOR SPOOL GUN KIT WIRING DIAGRAM.

N.G.

N.G.

B

43

12

P4, N.C.

J6 N.C.

1

2

3

4

J3

J4

J5

G-2

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The wiring diagram specific to your code is pasted inside one of the enclosure panels of your machine.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC