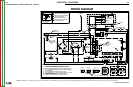

ElEcTrical DiaGramS

G-6

cOmpacT WirE WElDErS

SchEmaTic - cOmplETE machiNE m21240

2

7

CONNE

CT

O

R

PI

N

N

UM

BER

S:

CAPA

CIT

O

R: MF

D/

V

OLT

S

12

C

OM

PONE

NT

V

AL

U

E

U

NIT

S:

LABELS:

FR

AM

E

GROUND

1

C

OMM

ON

LE

A

D

C

OL

O

R

COD

E:

VIEW

OF

CONNEC

TO

RONPCBOARD

RE

SI

ST

O

R:

O

HM

S/

W

ATT

S

6

EX.

12

PIN CONNEC

TO

R

B-

BL

ACK

G-

GREEN

O-

ORANGE

R-

RED

U-

BL

UE

W-

W

HIT

E

Y-

Y

ELL

OW

LA

TCH

EA

RT

H

GROUND

EN-170

S

O

L

I

D

E

D

G

E

M2

1240

SM

ALL

W

IRE FEE

DE

R

W

ELDE

RS

MAC

HI

N

E SC

HEM

ATIC

NONE

-

DO NO

T

SC

AL

E

T

HIS DR

A

WING

EQ

UIP

M

ENT

TYPE:

SUBJECT:

SCA

L

E:

NA

CRM39439

1

PAGE ___ OF

___

1

E

NGI

N

EE

RI

NG

CO

NT

RO

LLE

D

MA

NU

FA

CT

URE

R:

No

THIS DOCUMENT CONTAINS PROPRIETAR

Y

INFORMATION OWNED B

Y

LINCOLN GLOBA

L, INC.

AND MA

Y

NOT BE DUPLICATED, COMMUNICATED

TO O

THER PARTIES OR US

ED FOR

AN

Y

PURPOS

E WITHOU

T

THE EXPRES

S WRIT

TEN PERMISSION

OF LINCOLN GLOBAL, INC.

PR

OP

R

IETA

R

Y &

CON

FI

DE

NTIAL:

t

MAT

ERI

A

L TO

L

ER

ANC

E ("

"

) TO A

GR

EE

WITH

PU

B

LI

SH

ED

ST

ANDARD

S.

ON A

LL

AN

GL

E

S I

S ± .5 OF

A D

E

GR

EE

ON

3

PLACE

D

E

CIM

ALS

IS

± .

00

2 i

n.

(

±

0.

0

5

mm)

ON 2

PL

AC

E D

ECIM

AL

S I

S ± .02 in. (

±

0.5 mm)

UNLESS OTHERWISE SPECIFIED TOLERANCE:

M

ANUF

ACTURING TO

L

ER

ANC

E

P

ER

E

2056

UPD

ATED FO

R

C

E MAC

HI

N

E.

CHAN

GE

D

ET

AIL:

REFER

ENCE:

MA

T

ERI

AL

DIS

PO

SI

T

ION:

AP

PRO

VA

L

DA

T

E:

PROJ

EC

T

NUMBER:

DOCUMEN

T

NUMBER:

DOCUMEN

T

REV

ISI

ON:

IF PR

IN

T

ED

@ A

1

SIZ

E

UNI

T

S:

IN

CH

6/6/

2008

cst

u

bl

e

B. ST

ELLE

R

.

DRAWN BY:

ENGINEER:

CL

EV

EL

AND

APPROVED:

CONTROL:

D

M21 240

Insight

C

B1

S1

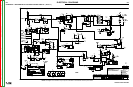

Two v

er

sions of INPUTS

180A un

it

s:208/230v

r

eta

il

and

i

ndus

tri

al

(

NEMA

)

6-

50 plug, 20 amps n

or

ma

l (

use 40 sup

er

l

a

g)

125A and 140A un

it

s: 120v

r

eta

il

and

i

ndus

tri

al

(

NEMA

)

5-

15plug,20amps

208/230v

r

eta

il

and

i

ndus

tri

al

r

equ

ir

eno

r

econnect of

i

nput.

But, at 208v

i

nput, the output

i

sd

er

ated to 17.6vdc

r

ated

loading.

D

if

f

er

ent case

fr

ont and nameplate

fr

om

r

eta

il

to

i

ndus

tri

a

l

v

er

sions.

Indus

tri

a

l

v

er

sionhasalu

mi

num ex

tr

uded

lifti

nghandleanda

plas

ti

c case back attached to the

r

e

ar

sheet meta

l

back.

D

if

f

er

ent c

or

dandplugf

or

both vo

lt

ages

120 and 230

i

nput = 25A / 250VAC

Same sw

it

chf

or

a

ll

machines

Fro

nt Cent

er

TopRe

ar

DutyCycle

(re

ta

il

&

i

ndus

tri

a

l):

180amp un

it

:

3

0% d

uty 130 amps @ 20 v

30 to 180 amps

OCV = 33 vdc

1

40 amp un

it

:

2

0% d

uty 90 amps @ 19.5v

30 to 140 amps

OCV = 33 vdc

1

25 amp un

it

:

2

0% d

uty 90 amps @ 19vdc

30 to 125 amps

OCV = 32 vdc

Too

ll

ess

Dr

ive Ro

ll

Change Ov

er

T

wist

l

ock type

dr

ive

r

o

ll

r

etain

er

c

li

p.

i

nn

er

/out

er

w

ir

es

li

de guide

Comes w

it

hun

it

:.025smooth

.035 smooth

.030/.045 kn

ur

led

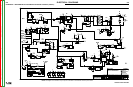

Vo

lt

age Con

tr

ol

Con

ti

nuous Con

tr

o

l

=10K~2to5vdca

cr

oss pot.

(i

ndus

tri

a

l

v

er

sions onl

y)

T

APCon

tr

o

l

5 pos

it

ions D to A =6.6v

( r

eta

il

v

er

sions onl

y)

B=7.6v

C=8.7v

F

= 9.8 v

G =14.2v

open= 15v

Ri gh t

Fr

ont

fi

xed

b

urn-

back

con

tr

ol

Vo

lt

age Con

tr

ol

c

irc

u

it

Tri

gg

er

C

irc

u

it

s

PWM

Con

tr

ol

Amp

li

fi

er

SCR Con

tr

ol

WFS Con

tr

ol

FET

Mot

or

Ov

er

load

and

F

eedback

FE

T

Con

tr

o

ll

er

bleed

er

r

esist

or

t

ur

ns on aft

er

tri

gg

er

r

elease

f

or

a

fi

xed

ti

me

.Thr

ee 5W,

51ohm

r

esist

or

s

i

n p

ar

a

ll

e

l.

Indus

tri

a

l

& Reta

il

v

er

sion:

has a potted

tr

ay

R

eta

il

e

ar

ly v

er

sion :

ar

e hu

mi-

sealed bo

ar

d

Same blank ,d

if

f

er

ent

vo

lt

age con

tr

o

l

p

ar

ts.

Tri

gg

er

St at us

CO

NT

R

OL

S

ARE

BOAR

D M

OU

NT

ED

WF

S 10

K ohms .7v to 9.1v

continuous

control (

no tap co

ntrol)

Left

Fr

ont

Top

Fr

ont

(l

ays

fl

a

t)

A

ll

meas

ur

ements made w

it

h

re

spect to Bo

ar

d Common

203 at

4-

J5

or1-

J3

open circui

t

typically equ

als

board inp

ut volts

Top Re

ar

GAS

SOLENOID

12vdc

r

ated 22 ohms

P

ul

l =12vdc,H

old

=6vdc

ov

er

load

pr

otected by PC bo

ar

d.

Shut off

i

sap

pr

ox. 1.25A of c

urr

ent

dr

aw

S

olenoidnot found

i

n 125A

r

eta

il

un

it

s.

Must

or

d

er

k

it

and

i

nsta

ll

.

15vdc

re

gulat

or

and

i

sol

+15vdc

203

Common

FAN

A

ir flow is back to front

(all versions

of all units

)

D

if

f

er

ent fan f

or

120

and 230

i

nput

Fan

r

uns a

ll

the

ti

me

Can not change plug to

make w

or

k w

it

h d

if

f

er

ent

input pow

er

l

evels

i

nthe

fi

eld

(f

act

or

yuseonl

y)

PCBpow

er

use

120V use

120V use

230V use

N.C.

19

-

30 VDC to

r

un

solenoid and one WFS

mot

or

at a

ti

me

203

Wo u nd

i

nside of

mai n

tr

ansf

or

m

er

(n

o

n-r

eplaceabl

e)

same th

er

mostat on a

ll

machines

D1

MAI

N

BRI

DG

E

Copp

er

f

or

the 180, and

alu

mi

num f

or

the 125 and 140.

T1

Base

Fr

ont below choke

3

"

stack f

or

125A v

er

sion

4" stack for 1

40 and 180

A

versions

C1

ri

ght out

er

plate

left and

ri

ght side

rear ar

ea

d

if

f

er

ent

br

idge f

or

230v

i

nput v

er

sions

left out

er

plate

ACAC

Use

Do

w

Corning

joint comp

ound

(T1283

7) to

reconnect

cap

BO

ARD

PO

WER

OUT

P

UT

CAP

base

r

e

ar

59,000mf/50vdc f

pr

120v

i

nput weld

er

s

120,000

mf/5

0vdc fpr 23

0v inpu

t

w

elders

C

HO

KE

below pc bo

ar

d

(a

lu

mi

nu

m)

ELE

CT

RO

DE

WO

RK

ri

ght

fr

ont

(for

w

ar

dstu

d)

ri

ght

fr

ont

(re

ar

stu

d)

Spool-

gun/

standar

d gun

s

wi

tch

(option

)

S26766

harness pl

ug

(timmer

option)

J6

low

er

case

fr

ont

4

2

543A

544A

Spool-

gun option K2532

-1

Magn

um 100 SG

Same motor control

circuits, but

for a small

er

motor

Reta

il

v

er

sion has a plas

ti

c

ge

ar

fr

ont housing.

Indus

tri

a

l

v

er

sion has a metal

housing

(

s

il

v

er

i

ncol

or).

Load com

pensated

type contr

ol for this

motor. Does not ten

d to stall if lin

er is

clogged like i

n older s

mall S

P

’s.

WFS Range :

50 to 500 +

i

pm

1.5 to 12.5 vdc

C

urr

ent L

im

it

to ap

pr

ox 2.5 amps

Gea

r Box

Feeder

Motor

ri

ght side

brass

bushing

MOT+

MOT-

TS1

FA

N

4

2

1

3

H2

H1

6

FA

N

TS2

1

TMP

TMP

opto

isola

ti

on

CO

NT

R

OL

P.

C.

BOARD

P

RIM

AR

Y SI

DE

CO

NT

R

OL

P.

C.

BOARD

SECONDAR

Y SI

DE

5

4

3B

1

21

5

B

2

2

B

3

2

0

3

B

4

5

4

4

B

5

4

B

6

4

C

2

C

2

1

5

B

20

3

B

4

B

2

B

5

4

3

B

1

2

2C

3

4

5

4

4

B

5

4

C

6

MOTOR

S

P

O

O

L

G

U

N

TRIGG

ER

+

-

O

PTI

ON

AL

SP

OT TIM

ER

P.

C.

BOARD

S

chematic

M20960

-1, -2 (C

E

VER

SI

O

N)

10

9

8

7

6

5

4

3

2

1

CAP-

CAP+

SOL

MOTB+

MOTB-

SOL

TMP

G

ND

TMP

CAP-

CAP+

SOL

MOTA+

MOTA-

SOL

TMP

GND

TMP

1

2

3

4

5

6

1

2

3

4

S

T

A

N

D

A

R

D

G

U

N

TRIGG

ER

19

-

30VDCto

r

un

solenoid and one WFS

mot

or

at a

ti

me

PWM Con

tr

ol

and Ov

er

load

P

ro

tec

ti

on

203

+15VDC

Control

Board

Trigger Circuit

OPE

N

= 0

V

CL

OSE

D

= 13.8

V

Trigger

from gu

n

when measuring fro

m

pin 2 to g

round

OPE

N

= 0

V

CL

OSE

D

= 9.8

V

when measuring

between pins 1 and 2

OPE

N

= 15

V

CL

OSE

D

= 0

V

J7

P3

10

98

7

6

54

3

2

1

J3

P7

J8

J9

P8

J5

P9

P4

J4

R

+15VDC

+

1

2

3

4

5

6

P5

stand

ar

d

use plu

g-

in

B

R

W

W

ti

m

er

op

ti

on

spoo

l

gun

op

ti

on

1

2

3

4

5

6

M21182

harness pl

ug

(spool gu

n option)

spoo

l

gun

op

ti

on

w

ir

e

r

ee

l

cent

er

pane

l

ar

ea

use one o

r the othe

r but

not both at the same time

w

ir

e

r

ee

l

cent

er

pane

l

ar

ea

Schema

ti

c: G4822

= spot

ti

m

er

op

ti

on&w

iri

ng

=spoo

l

gun op

ti

ons & w

iri

ng

=fact

or

yconnec

ti

ons to con

tr

o

l

bd.

s

ho

w

nin

std

.

gun p

os

itio

n

10

98

7

6

54

3

2

1

BACK O

F

OUTPU

T

STUD

(o

nCEv

er

siononl

y)

OC

V

RANGE

10 - 35V (IN

P

UT

V

OLT

AG

E

DEPENDE

NT)

1

2

3

4

5

6

7

8

+15VDC +15VDC

CW

CCW

P1

J1

B

W

Logic

Spot

T

im

e

Fu

ll

CCW

=O

FF

Adjusts

fr

om

200mS to 10S

TH

E

RM

AL L

ED

PM180

C (

C

E)

VER

SI

O

N

O

NL

Y

Upp

er

l

eftc

or

n

er

of

Cas e

Fr

ont

65

FILTE

R

P.

C.

BD

O

N

C

E M

AC

HI

NES

O

NL

Y

G-6

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC