OPERATION

B-4 B-4

COMPACT WIRE WELDERS

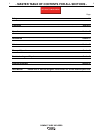

See Figure B.3

8. WELDING GUN CONNECTOR BUSHING &

THUMBSCREW – Provides electrical power to the

welding gun. The thumbscrew holds the welding gun

into the connector block. (Front of Machine, Side

Door and Wire Drive Cover have been removed for

clarity of Items 8 and 9).

9. OUTPUT TERMINALS –These connections allow

for changing the output polarity of the machine

depending on whether you are MIG welding (+) or

flux-cored welding (-)-.

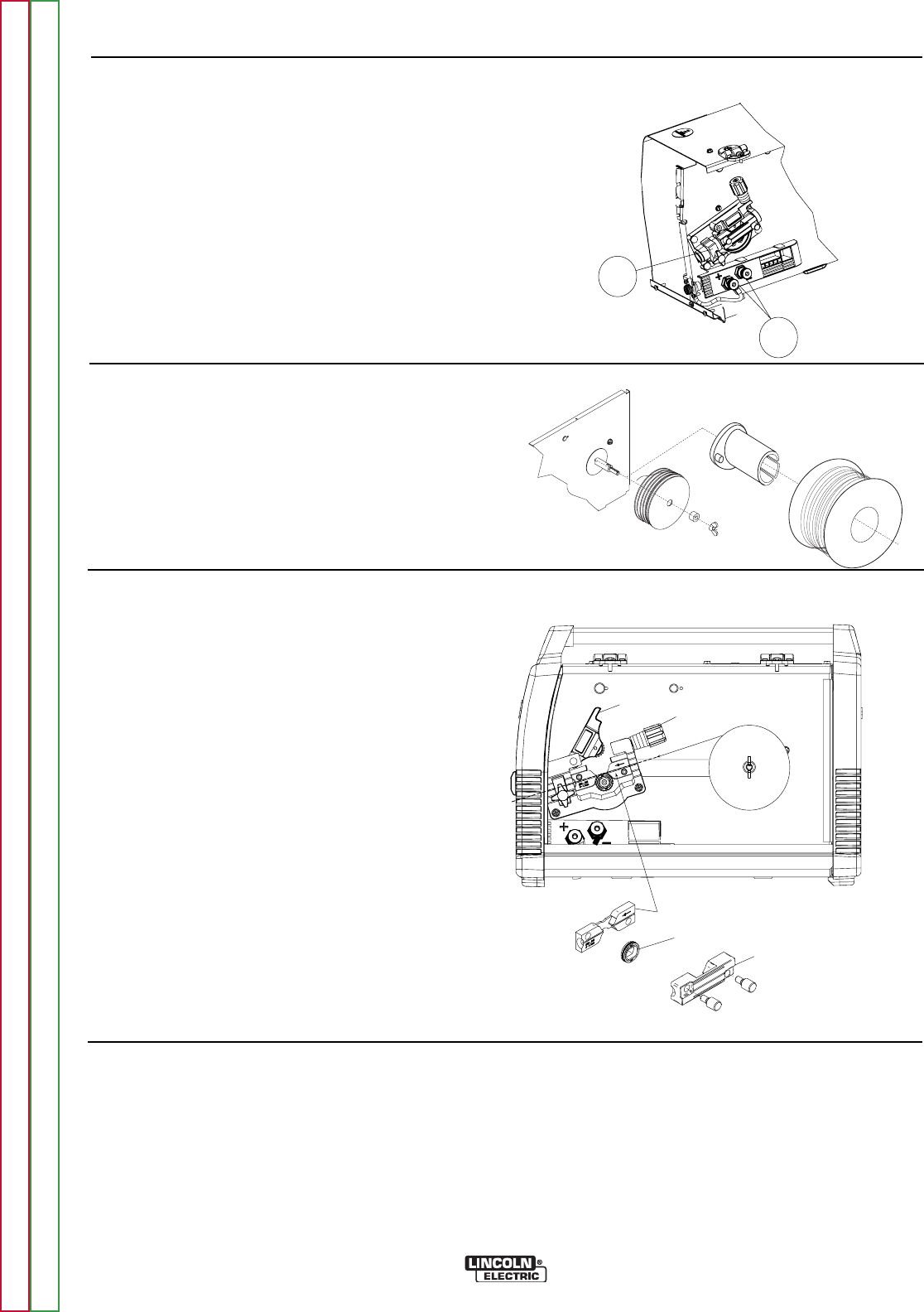

See Figure B.4

10. WIRE SPOOL SPINDLE AND BRAKE – Holds a

4”(102mm) diameter spool. Use the 2”(51mm)

spindle adapter included with the machine to use

8”(203mm) diameter spools. The wing nut sets the

brake friction to prevent the spool from over rotat-

ing when the trigger is released.

See Figure B.5

11. WIRE DRIVE & COMPONENTS (ALUMINUM

DRIVE HOUSING) – Feeds wire from the wire

spool through the drive and through the welding

gun to the weld.

a. Top and Bottom Drive Roll – Drives the wire

through the drive system. The drive roll has a

groove to match the specific wire type and diam-

eter. Refer to Table B.1 for available drive rolls.

b. Inner & Outer Wire Guide – Guides the wire

between the Top and Bottom Drive Roll and

through the wire drive. The inner guide has a

groove to match a particular wire diameter. Refer

to Table B.1 for available wire guides.

c. Drive Roll Tension Thumbscrew – Turning

clockwise increases the force on the drive rolls

and turning counterclockwise decreases the

force.

8

9

FIGURE B.3

2"(51mm) SPINDLE ADAPTER (FOR 8"(20mm) REEL OF WIRE)

( 4"(102mm) REEL OF WIRE)

FIGURE B.4

FIGURE B.5

WIRE SPOOL

.035" (0.9mm)

NR-211-MP

INNER WIRE GUIDE REMOVED

LOWER DRIVE ROLL REMOVED

OUTER WIRE GUIDE REMOVED

TOP DRIVE ROLL PRESSURE ARM

TENSION ADJUSTOR DOWN

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC