OPERATION

B-5 B-5

COMPACT WIRE WELDERS

TABLE B.1

DRIVE ROLL AND WIRE GUIDES

Wire Diameter &

Type

.025”(0.6mm) MIG wire

.030”(0.8mm) MIG wire

.035”(0.9mm) MIG wire

.030”(0.8mm) flux-cored

.035”(0.9mm) flux-cored

.045”(1.1mm) flux-cored

Drive Roll

.025”/.030” (0.6mm/0.8mm)

Smooth Drive Roll

.035”(0.9mm) Smooth Drive Roll

.030”/.045” (0.8mm/1.1mm)

Knurled Drive Roll

.030”/.045” (0.8mm/1.1mm)

Knurled Drive Roll

Inner Wire Guide

.025”-.035”

(0.6mm-0.9mm)

Steel Wire Guide

.045”(1.1mm)

Steel

Wire Guide

Inner Wire Guide

Part Number

KP2531-1

KP2531-2

Drive Roll Part

Number

KP2529-1

KP2529-2

KP2529-3

KP2529-3

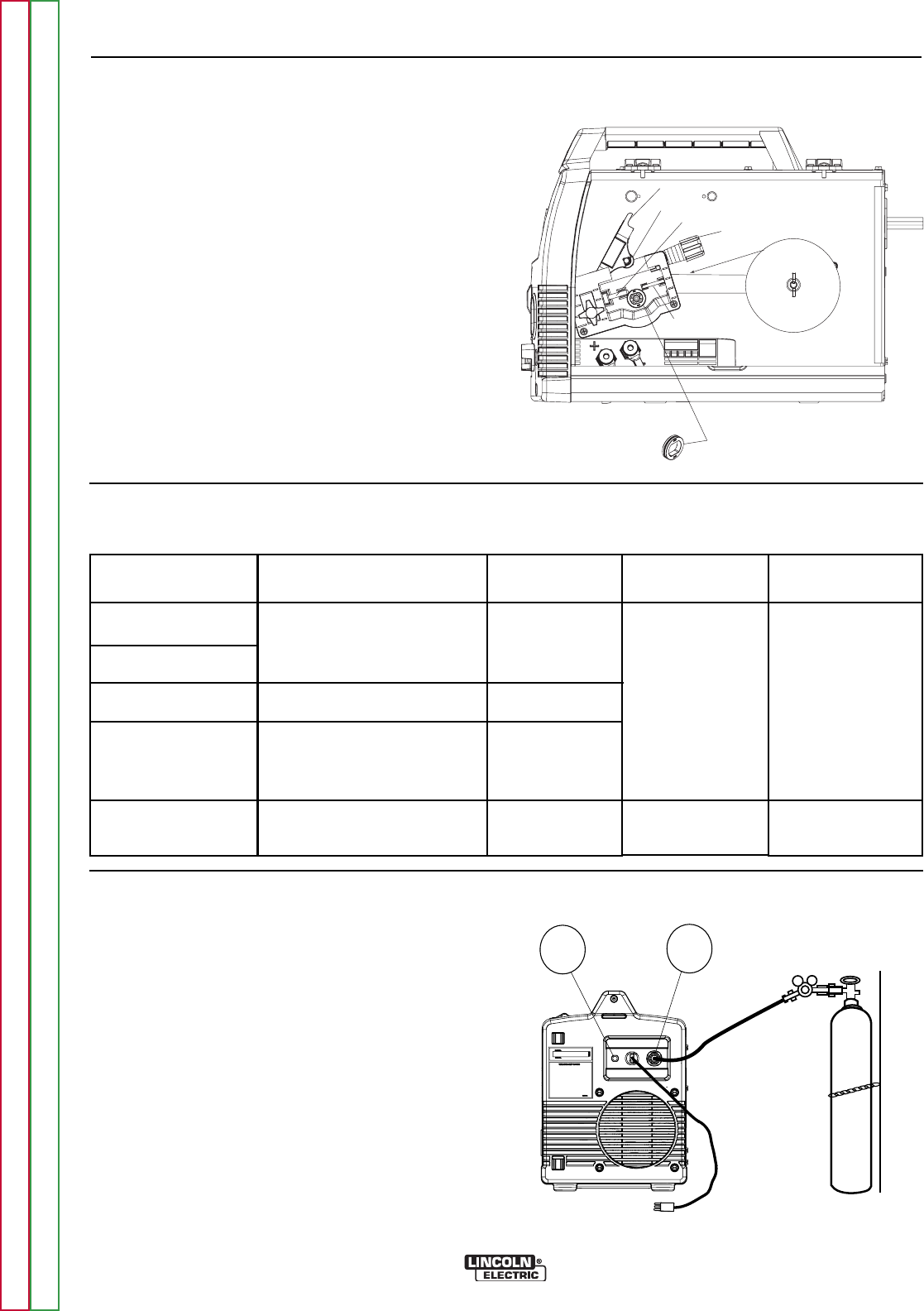

See Figure B.6

12. CIRCUIT BREAKER – If the rated input current of

the machine is exceeded this circuit breaker will

trip. Press to reset.

13. GAS INLET – Shielding gas connects to this inlet.

NOTE: Only on 125 amp machines that have added

the MIG Conversion Kit (K2525-1)

12

13

FIGURE B.6

See Figure B.5a

11a. WIRE DRIVE & COMPONENTS (MOLDED

DRIVE HOUSING) – Feeds wire from the wire

spool through the drive and through the welding

gun to the weld.

a. Drive Roll – Drives the wire through the drive

system. The drive roll has a groove to match the

specific wire type and diameter. Refer to Table

B.1 for available drive rolls.

b. Liner & Outgoing Guide – The liner guides the

wire between the bearing on the Pivot Arm

Assembly and Drive Roll and through the outgo-

ing guide.

c. Drive Roll Tension Thumbscrew – Turning

clockwise increases the force on the drive roll

and turning counterclockwise decreases the

force.

WIRE SPOOL

.035" (0.9mm)

NR-211-MP

PIVOT ARM ASSEMBLY

TENSION ARM ASSEMBLY

LINER

DRIVE ROLL

OUTGOING GUIDE

BEARING

FIGURE B.5a

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC