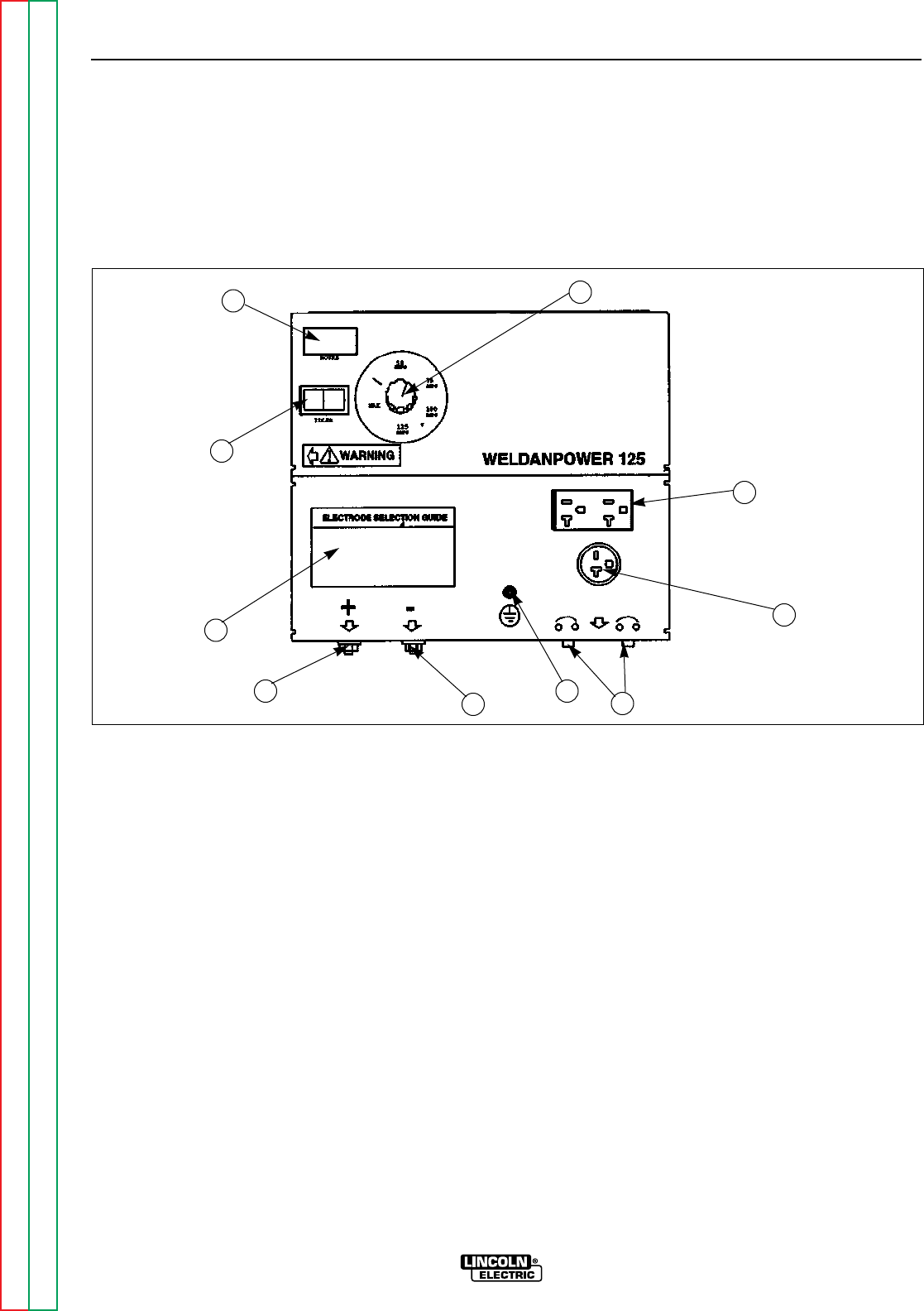

WELDER/GENERATOR CONTROLS

See Figure B.1 for the location of the following fea-

tures:

1. CURRENT CONTROL DIAL: Adjusts continuous

current output. The amperages on the dial corre-

spond to the average amperages needed for spe-

cific Lincoln welder rods.

2. ELECTRODE SELECTION GUIDE: Provides rec-

ommended electrode type, size, and welder out-

put setting based on the thickness of the work.

3. WELD POSITIVE OUTPUT TERMINAL WITH 1/2 -

13 FLANGE NUT: Provides the connection point

for either the electrode holder or the work cable.

(For DC+ welding the electrode holder should be

connected to the Weld Positive Output Terminal

and the work cable to the Weld Negative Output

Terminal. For DC– welding the electrode holder

should be connected to the Weld Negative Output

Terminal and the work cable to the Weld Positive

Output Terminal.)

4. WELD NEGATIVE OUTPUT TERMINAL WITH 1/2 -

13 FLANGE NUT: Provides the connection point

for either the electrode holder or the work cable.

(For DC+ welding the electrode holder should be

connected to the Weld Positive Output Terminal

and the work cable to the Weld Negative Output

Terminal. For DC– welding the electrode holder

should be connected to the Weld Negative Output

Terminal and the work cable to the Weld Positive

Output Terminal.

OPERATION

B-4 B-4

WELDANPOWER 125

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

1. CURRENT CONTROL DIAL

2. ELECTRODE SELECTION GUIDE

3. WELD POSITIVE OUTPUT TERMINAL WITH 1/2 - 13 FLANGE NUT

4. WELD NEGATIVE OUTPUT TERMINAL WITH 1/2 - 13 FLANGE NUT

5. GROUND STUD

6. 20 AMP CIRCUIT BREAKERS (2) (15 AMP CSA)

7. 20 AMP, 230 VOLT RECEPTACLE (15 AMP CSA)

8. 20 AMP, 115 VOLT DUPLEX RECEPTACLE (15 AMP CSA)

9. HOUR METER

10. IDLER CONTROL SWITCH

FIGURE B.1 – OUTPUT PANEL CONTROLS

CONTROLS AND SETTINGS

All welder/generators controls are located on the

Output Control Panel. Gasoline engine controls are

mounted on the engine. See Figures B.1 and B.2 and

the explanations that follow.

9

1

10

2

3

4

5

6

7

8