Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-9 F-9

WELDANPOWER 125

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

216-383-2531 or 1-800-833-9353.

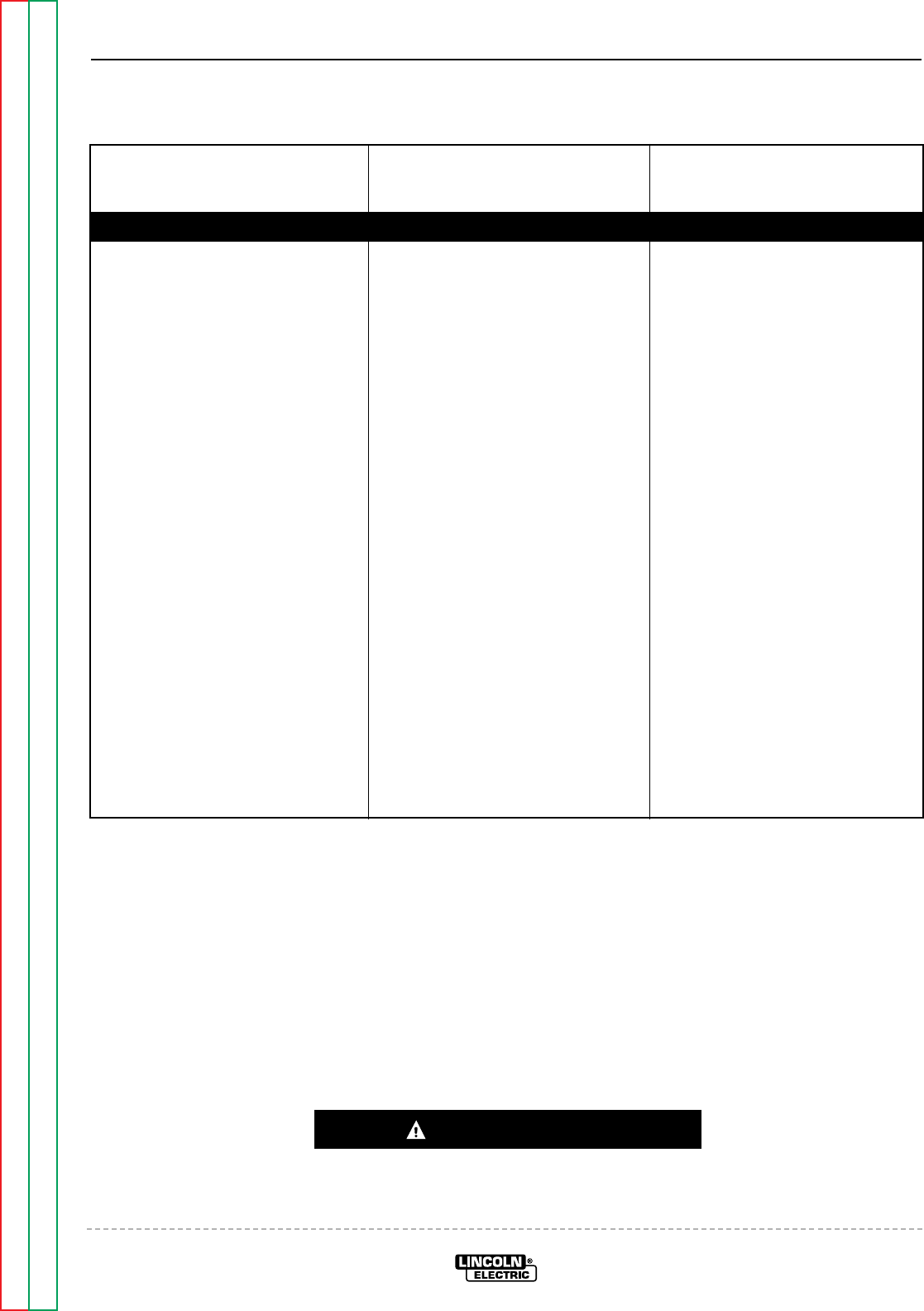

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

ENGINE PROBLEMS

Engine will NOT idle down to low

speed.

1. Make sure the idler control

switch is in the “AUTO” idle

position.

2. Remove any external load on

the welder terminals or auxiliary

power receptacles.

1. With the idler control switch in

the “AUTO” position and all

external loads removed, check

for 12VDC at leads #208 and

#209. See Wiring Diagram. If

the 12VDC is present and the

idler solenoid does not activate,

the solenoid may be faulty.

Replace.

2. If the 12VDC is NOT present at

leads #208 and #209, perform

the Main Stator Winding Test.

3. Check leads #15A (at stator) to

#16 (at idler P.C. board) for con-

tinuity (zero ohms). Check

leads #9A (at stator) to #9B (at

idler P.C. board) for continuity

(zero ohms). See Wiring

Diagram.

4. The idler P.C. board may be

faulty. Replace.