48

SETTINGS AND ADJUSTMENTS

SECTION 4-13

Adjusting or Replacing Rotor Knives

CLEAN PARTS FOR REASSEMBLY

Clean the rotor knife seats with a stone or other

non-mar- ring tool. Make sure that the backs of the

knife seats are clean so that the rotor knife can be

placed squarely against them.

Wipe the screws with lightly oiled cloth, do not

leave an oil film since lubrication can adversely

affect the stress on a screw installed to a fixed

tor

q

ue value.

DO NOT REPLACE THE MOUNTING SCREWS WITH ANY TYPE OF SCREW

OTHER THAN THAT SPECIFIED BY STERLING. Substitution of improper screws could

lead to premature failure, equipment damage, and serious injury to personnel.

When regrinding the knives, you may re-use the same screws and washers but do not re-use them

more than six times. When installing new knives, replace the screws and washers with those

furnished by the factory.

ROTORS WITH REPLACEABLE KNIFE SEATS

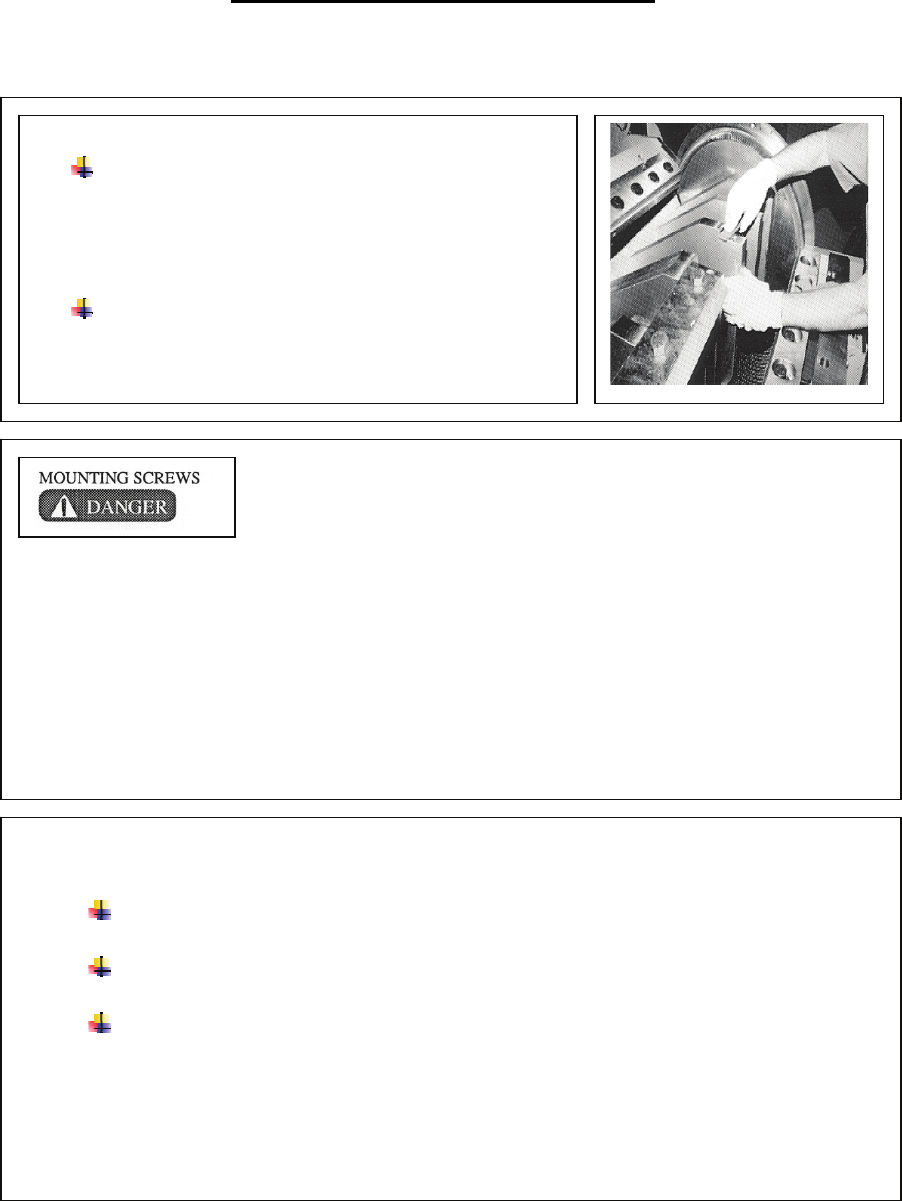

Check the replaceable knife seat screws for proper torque. PHOTO

Rotor with replace seats

The proper torque value for these screws is 235 ft lbs.

This should be carried out at regular set maintenance intervals.