78

MAINTENANCE

SECTION 6-1

Periodic Maintenance

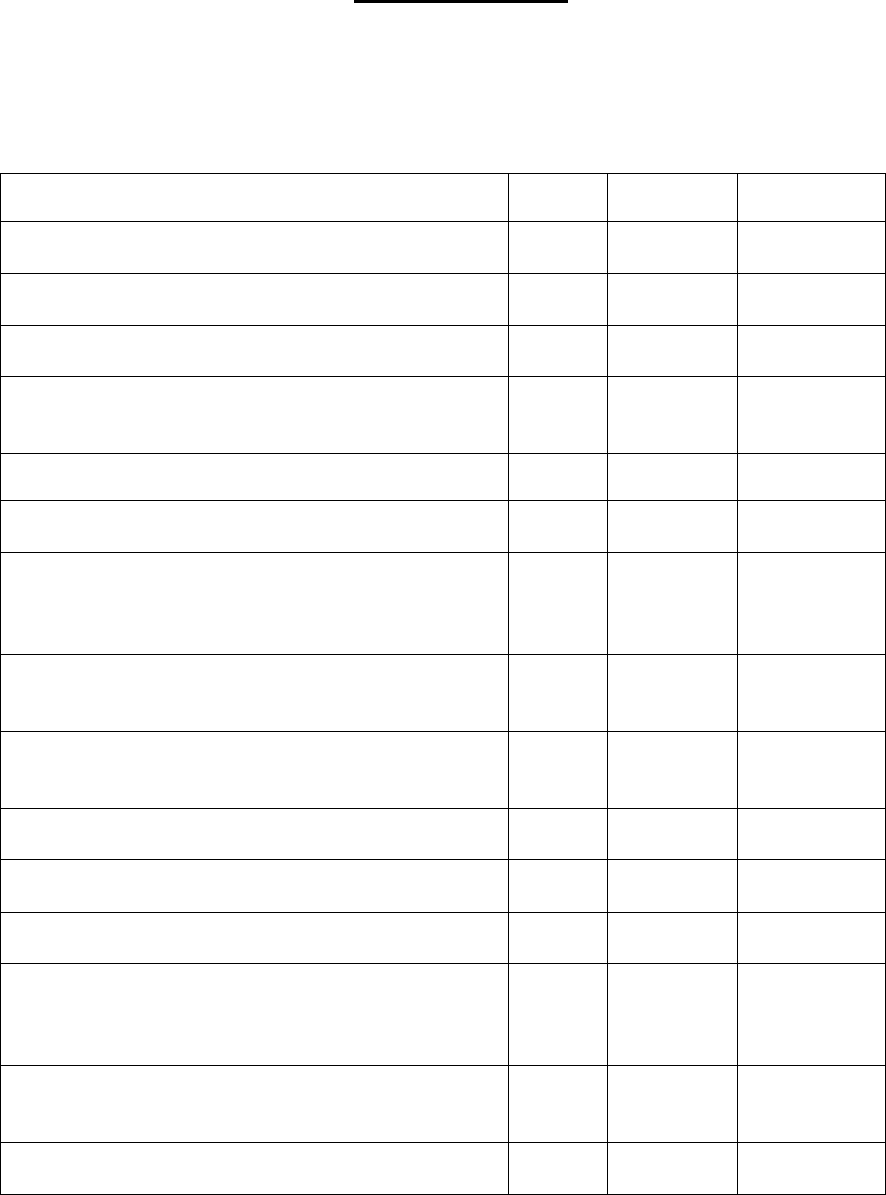

TABLE 1: PERIODIC MAINTENANCE SCHEDULE

CHECK DAILY WEEKLY MONTHLY

Check tightness of upper chamber hold down handles.

Refer to Section 6, Cutting Chamber

X

Check tightness of screen chamber wedges. Refer to

Section 6, Screen Replacement

X

Check infeed flap position/condition. Refer to Section

6 Periodic Maintenance

X

Check interlock actuator switch screws

position/condition. Refer to Section 6 Screen

Replacement/Cutting Chamber Access

X

Do housekeeping around work area

X

Check tightness of upper pivot arm screws. Refer to

Section 6 Periodic Maintenance

X

Check jackscrew travel adjustment – internal limit

switches and chamber mounting bracket limit switch.

Refer to Section 4, Setting And Adjusting

Chamber.Cradle3 Jackscrews

X

Check hydraulic assembly –limit switches, hoses,

pivot pins, brackets ensure they are tight Refer to

Section 4-36 Setting And Adjusting hydraulic opening.

X

Check the pivot pins and locknuts for the jackscrews to

ensure they are tight. Refer to Section 6 Periodic

Maintenance

X

Inspect overall condition of jackscrews. Refer to

Section 6 Periodic Maintenance

X

Check Zero Speed Sensor operation. Refer to Section

3, Installation-Test the Zero Speed Sensor

X

Check knife clearance and wear. Refer to Section 4,

Adjusting and Replacing the Rotor Knives.

X

Check that rotor and bed knife bolts have proper

torque. Refer to Section 4, Adjusting and Replacing

the Rotor Knives/Adjusting and Replacing the Bed

Knives.

X

Lubrication: More frequent lubrication may be

required, refer to Section 6, Lubrication and Periodic

maintenance

X

Belt tension. Refer to Section 4, Settings and

Adjustments

X