1 Quick Reference

12 Series N5700 User’s Guide

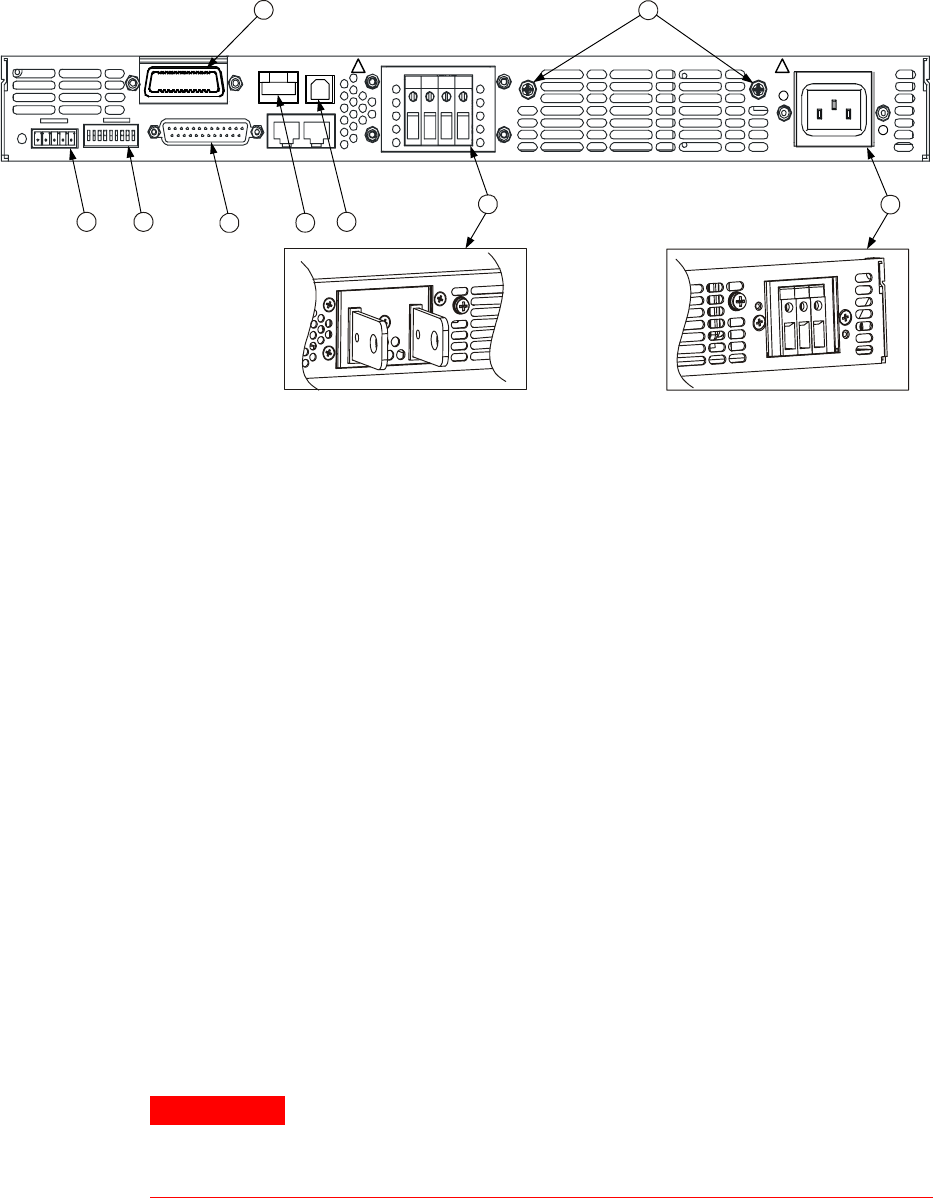

The Rear Panel – At a Glance

9

5

7 3

8

4

6

1

2

750W

1500W6V - 60V

80V - 600V

AC INPUT

ON

OFF

+V -V

NOT ACTIVE

J2

SW1

GPIB

ANALOG PROGRAMMING

+S+LS NC -LC-S

1 2 3 4 5 6 7 8 9

10/100 Ethernet

LINK TX

J1

! !

1 – AC input connector Wire clamp connector for 1500W output models.

IEC connector for 750W output models.

2 – DC output connector Wire clamp connector for 80V to 600V models.

Bus bars for 6V to 60V models.

3 – USB connector Connector for connecting to a USB interface. See chapter 4 for setup.

4 – LAN connector Connector for connecting to a LAN interface. LINK LED indicates link integrity.

TX LED indicates LAN activity. See chapter 4 for LAN setup.

5 – Analog Programming

connector

Connector for the analog interface. Includes output voltage and current limit

programming and monitoring signals, Shut-Off control (electrical signal),

Enable/Disable control (dry-contact), power supply ok (Power Supply OK) signal

and operation mode (CV/CC) signal. (See next page for details)

6 – SW1 setup switch Nine-position switch for selecting remote programming and monitoring modes

for Output Voltage, Current Limit and other control functions. (See next page for

details)

7 – Remote Sense connector Connector for making remote sensing connections for regulating the load

voltage and compensating for wiring voltage drop. (See next page for details)

8 – GPIB connector Connector for connecting to a GPIB interface. See chapter 4 for setup.

9 – Ground screw M4x8 screws for making chassis ground connections

WARNING

SHOCK HAZARD The power cord provides a chassis ground through a third

conductor. Be certain that your power outlet is of the three-conductor type

with the correct pin connected to earth ground