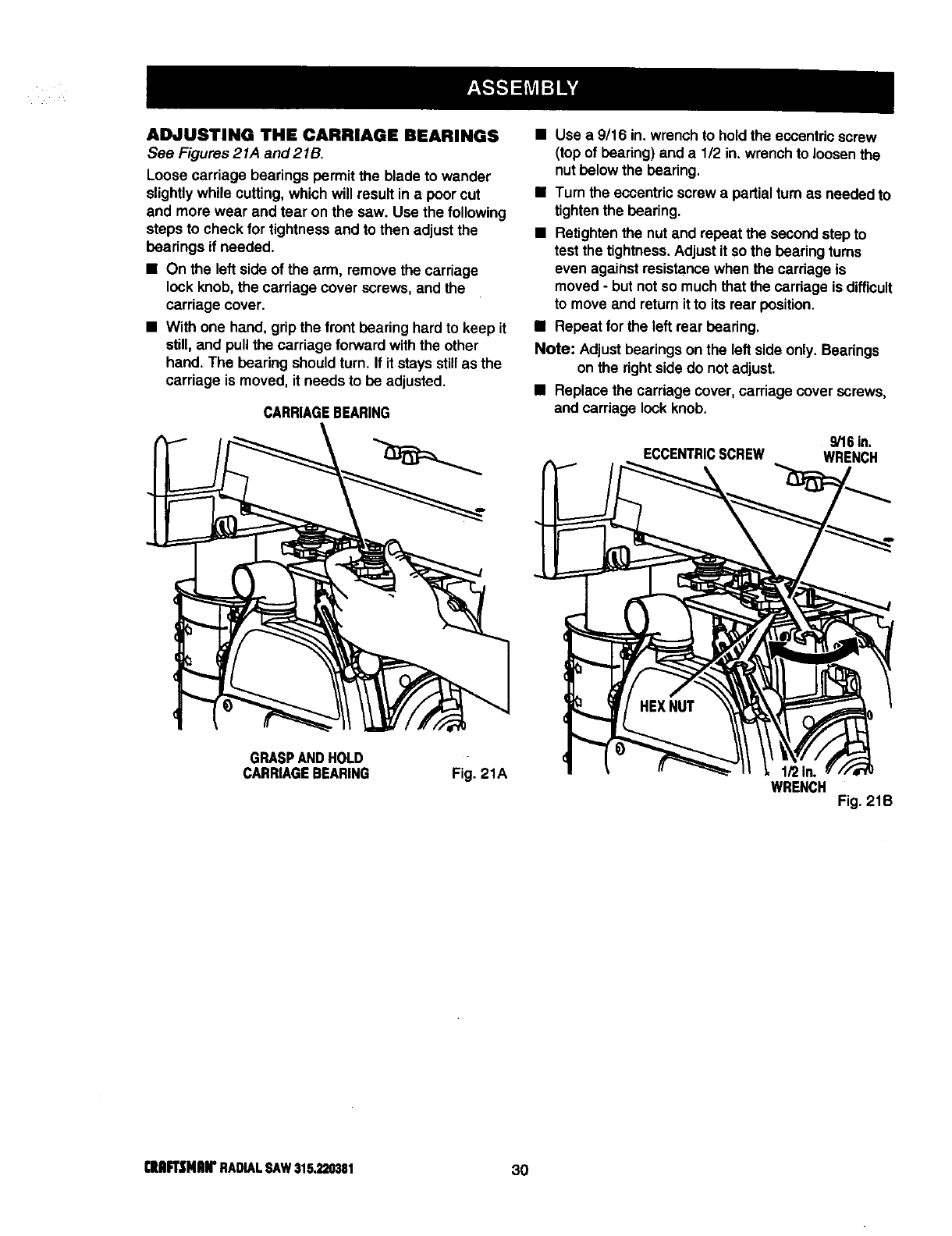

ADJUSTING THE CARRIAGE BEARINGS

See Figures 21A and 21B.

Loosecarriage bearings permit the blade towander

slightlywhile cutting,whichwillresult in a poorcut

and more wear and tear onthe saw. Use thefollowing

steps to check for tightness and to then adjust the

bearings if needed.

• On the leftside of the arm, remove the carriage

lock knob, the carriage cover screws, and the

carriage cover.

• With one hand, grip the frontbearing hardto keep it

still, and pull thecarriage forward withthe other

hand. The bearing shouldturn. Ifitstays stillas the

carriage ismoved, it needs to be adjusted.

CARRIAGEBEARING

• Use a 9/16 in.wrench toholdthe eccentricscrew

(top of bearing)and a 1/2 in.wrenchtoloosen the

nutbelow the bearing.

• Turn the eccentricscrew a partialturnas neededto

tightenthe bearing.

• Retightenthe nut and repeat thesecond stepto

test thetightness.Adjustitsothe bearing turns

even againstresistancewhen the carriage is

moved - but notso much thatthe carriage isdifficult

to moveand returnitto its rear position.

• Repeat for theleft rear bearing.

Note: Adjustbearings on the leftside only. Bearings

on the rightsidedo not adjust.

• Replace the carriage cover,carriage cover screws,

and cardage lock knob.

9/16in.

ECCENTRICSCREW WRENCH

GRASPANDHOLD

CARRIAGEBEARING Fig. 21A

WRENCH

Fig. 21B

C|Al_Nlnr RADIALSAW315.220381 30