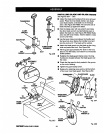

PARALLELING BLADE TO TABLE

See Figures 32A-32C.

This procedure squares the blade to the table at 90"

bevel so horizontalcutswill be accurate. This also

reduces kickback,as well as splinteringand burning

of the cut edges of the workpiece. If the blade is not at

90" bevel, follow the stepsto rotate the blade unit

slightly.You willneed a framing square and a flat

blade screwdriver.

_k WARNING: The blade mustbe perfectlyparallel

to thetable at the 90" reading on the bevel scale,

If not, kickbackcould result,as well as splinter-

ingor burningthe cut. Kickbackcan resultin

serious personal injuryas the workpiece can be

thrown at the operator.

• Use the arm lock knobto lock thearm in 0° miter

position(straightforward).

• Turn the elevating handwheel to raisethe bladeat

least 2 in.above the table.

Release the bevel lock lever belowthe handle. Use

the bevel indexknob, just under the handle, toturn

the motorto 90". The blade willbe horizontal. Lock

the bevel lock lever.

• Placethe framing square withthe shortend hang-

ingdownin frontofthe worktableand the longside

on edge underthe blade.

• Lowerthe arm withthe elevating handwheelsothe

bladesurface restson the square. Turn the blade

slightlyifnecessary sothe face ofthe blade, nota

tooth, lieson the square.

NOADJUSTMENT

NEEDED

FENCE

BEVEL

LEVER

BLADE

FRONTTABLE

FRAMING

SOUARE

Fig. 32A

• Check whetherthe blade isfiat againstthe edge

the entirelengthor whether a gap is visible.Ifyou

can see a gap, adjustthe bladeto be at 90" bevel

tothe table with the followingsteps.

• Unlockthe bevel locklever. Loosenthe rearmotor

mountnut,whichholdsthe motoron the yoke,

Placea flatblade scrawddver inone of the slots,

and rotatethe cam behind the nutto eliminatethe

gap betweenthe bladeand the square.

• Retightenthe nut.

• Tightenthe bevel lock lever. Recheck the blade

and the square forany gaps.

• Raise the bladewith the elevating handwheelto

approximatelyhalfwayup. Index the bladeto a

vertical0° bevel with the bevel index knob. Lockit

with the bevel locklever.

ADJUSTMENT GAP

NEEDED

:=A--

GAP

Fig. 32B

CAM'

Fig. 32C

[RIIFrSMIIIr RADIALSAW315.220381 40