RIP CUT HAZARDS AND PRECAUTIONS

Two hazards are specificallyassociated with rip

cutting:outfeed zone and wrong way feed,

In the ouffeedzone (behind the blade), the blade

teeth pointdown. The slightestcontact whilethe blade

is stillspinningcan snag clothing,jewelry, the work-

piece, or even skin, causing seriouspersonal injury.

Wrongway feed occurswhen the workpiececontacts

the blade from the ouffeedside. It is very hazardous

and willjerk the workpiece violently.You could be cut

ifyou are holdingthe workpiece.

,_k WARNING: Failure to observe any ofthese

precautionscan result inserious injury.

• The first precaution is, ofcourse, simplyto stay

completely away from the ouffeed zone. Keep

handsaway from the outfeed zone.

• Pointthe anti-kickback pawls away from the blade

teeth to snag a workpiece ifthe blade grabs. They

should be positionedto rest lightlyon the

workpiece.The flat side of the pawls should be

level and horizontal.

• Set the rivingknifeto just clear the table.

• Set the hold downin front ofthe bladeto just clear

the workpiece.

• Start and finish yourcut from the infeed side.

• Push the workpiece past the pawls with push-

blocksand pushstickstofinish the cut.

• If the blade jams, turnthe saw offwith the switch

on the arm, remove the yellow key, and waitfor the

blade to fullystop beforefreeing it.

• Make sure the blade is parallelto the fence and the

workpiece is not warped or twisted.

• Make sure no pressure isapplied to the workpiece

on the ouffeedside.

• Make sure the blade guard is lowered and is

workingproperly.

• Alwaysset up the workpiece so the wider part of

the wood is between the blade and the fence. This

stabilizesthe workpiece better.

• Do not release the workpiece until ithas moved

pastthe pawls. Keep pushsticksfirmly in place.

• Use pushsUcksand pushblocks,not yourhands,

when the trailing edge of the workpiece iswithin

3 in. ofthe blade. Ifthe blade isset 2 in. or more

from the fence, use a pushstiok.Use a pushblock

and auxiliaryfence when the blade is between 2 in.

and 1/2 in.from the fence. (If the cut isnarrower

than 1/2 in., use a different saw.) For large panel

ripcuts, use a featherboard instead of pushblocks

or pushsticks.See the sectionon CuttingAids.

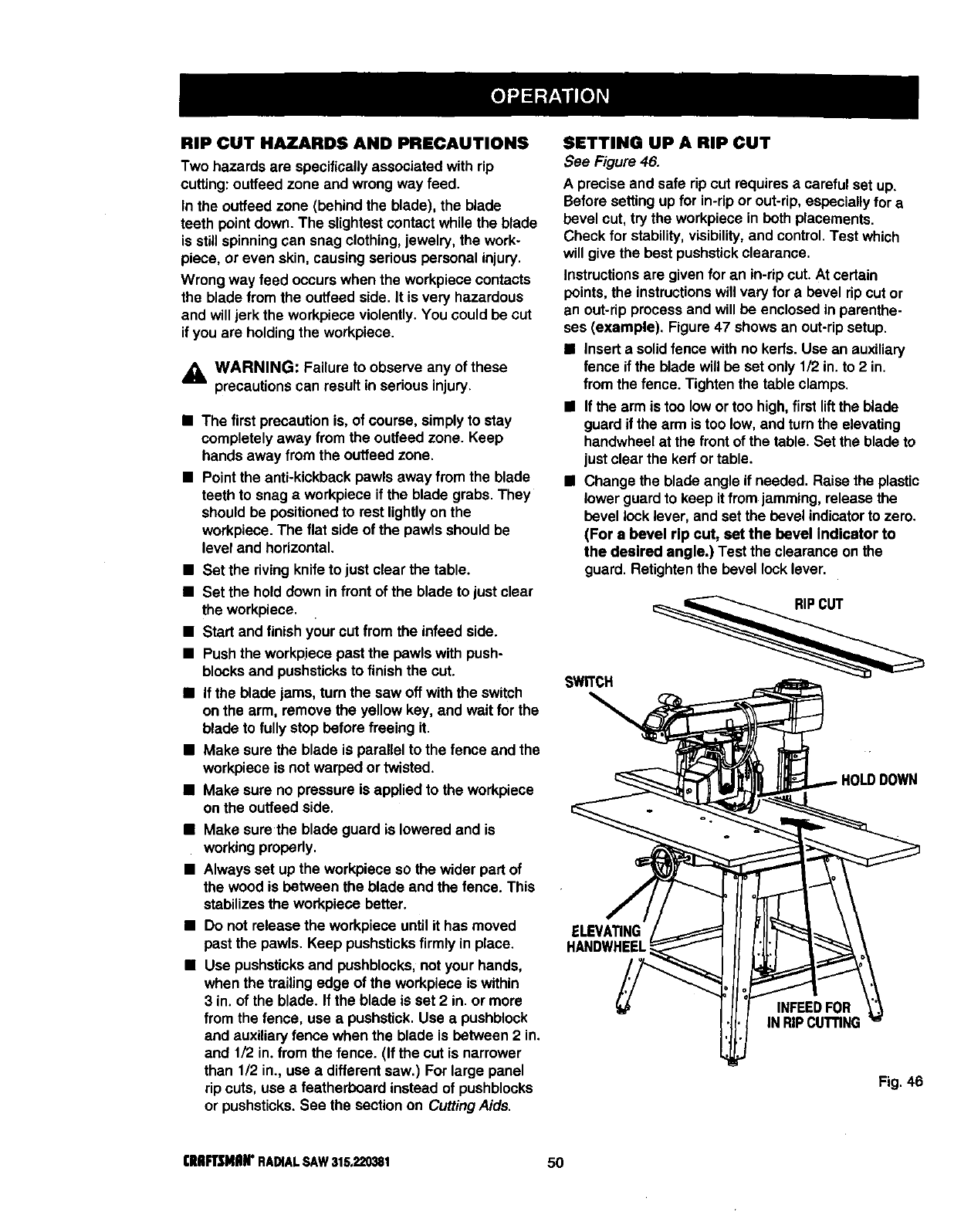

SETTING UP A RIP CUT

See Figure 46.

A preciseand safe ripcutrequires a careful set up.

Beforesettingup for in-ripor out-rip, especiallyfor a

bevel cut, trythe workpiece in both placements.

Check for stability,visibility,and control.Test which

willgive the best pushstickclearance.

Instructionsare givenfor an in-ripcut. At certain

points,the instructionswillvary for a bevel ripcut or

an out-ripprocessand will be enclosed in parenthe-

ses (example), Figure47 shows an out-ripsetup.

• Inserta solidfence withno kerfs. Use an auxiliary

fenceif the bladewillbe set only 1/2 in.to2 in.

from the fence. Tighten the table clamps,

• Ifthe armis too lowor too high,firstliftthe blade

guard ifthe arm istoo low, and turnthe elevating

handwheelat thefrontof the table. Set the bladeto

justclear the kerf or table.

• Change the bladeangle if needed. Raise the plastic

lowerguard to keep itfromjamming, release the

bevel lock lever,and set the bevel indicatorto zero.

(For a bevel rip cut, set the bevel Indicator to

the desired angle.) Test the clearance on the

guard. Retightenthe bevel lock lever.

ELEVATING

HANDWHEEL

INFEEDFOR

IN RIPCUTTING

Fig. 46

I'IIIIFTSMIIIP RADIALSAW315.220381 50