Appendix B Accessories|VFD-S Series

Revision August 2006, SE08, SW V2.61 B-3

B.2 EMI Filters

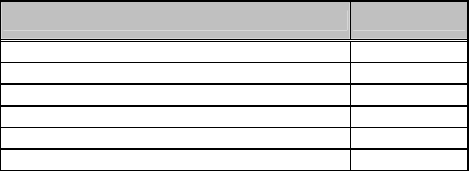

The DELTA VFD-S Series 0.25-3HP, 115V, 230V, 460V AC drive uses DELTA EMI Filter. Use the

table below to find the appropriate filter for your DELTA VFD-S drive.

Model of AC Motor Drive EMI Filter

VFD002S21A/B, VFD004S21A/B, VFD007S21A/B RF007S21AA

VFD015S21D/U, VFD022S21D/U RF022S21BA

VFD004S43A/B, VFD007S43A/B RF007S43AA

VFD002S11A/B, VFD004S11A/B 12DKT1W3S

VFD002S23A, VFD004S23A, VFD007S23A 08TDT1W4S

VFD007S11A/B 22DRT1W3S

Installation

All electrical equipment, including AC motor drives, will generate high-frequency/low-frequency noise

and will interfere with peripheral equipment by radiation or conduction when in operation. By using

an EMI filter with correct installation, much interference can be eliminated. It is recommended to use

DELTA EMI filter to have the best interference elimination performance.

We assure that it can comply with following rules when AC motor drive and EMI filter are installed

and wired according to user manual:

EN61000-6-4

EN61800-3: 1996 + A11: 2000

EN55011 (1991) Class A Group 1 (1

st

Environment, restricted distribution)

General precaution

1. EMI filter and AC motor drive should be installed on the same metal plate.

2. Please install AC motor drive on footprint EMI filter or install EMI filter as close as possible

to the AC motor drive.

3. Please wire as short as possible.

4. Metal plate should be grounded.

5. The cover of EMI filter and AC motor drive or grounding should be fixed on the metal plate

and the contact area should be as large as possible.

Choose suitable motor cable and precautions

Improper installation and choice of motor cable will affect the performance of EMI filter. Be sure to

observe the following precautions when selecting motor cable.