OPERATION

B-4 B-4

V160-S & -T

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

7. Remote LED: This indicator will turn on when a

remote control is connected to the machine via the

remote control connector. Using a remote control

will change the function of the output current control,

refer to the output current control section below.

8. Output LED: This indicator turns on when the output

of the machine is on.

• In stick welding mode, the output of the machine is

automatically turned ON.

• In Lift TIG welding mode without a remote control,

the output of the machine is automatically turned

ON. In this condition a triggering device is not need-

ed.

• In Lift TIG welding mode with a remote control, the

output of the machine is turned ON and OFF by the

remote device (i.e. hand or foot amptrol) connected

to the remote connector on the front of the machine.

Output must be triggered ON (output LED lit) to

enable Lift TIG starting. After machine output is trig-

gered ON, the arc must be started within 6.5 sec-

onds or output will turn OFF and trigger sequence

must be restarted. (Note: Any remote control device

with trigger-only circuit, such as the K814 Arc Start

Switch, will not be sensed by the V160-S remote

control connection, and therefore will not allow con-

trol of the output).

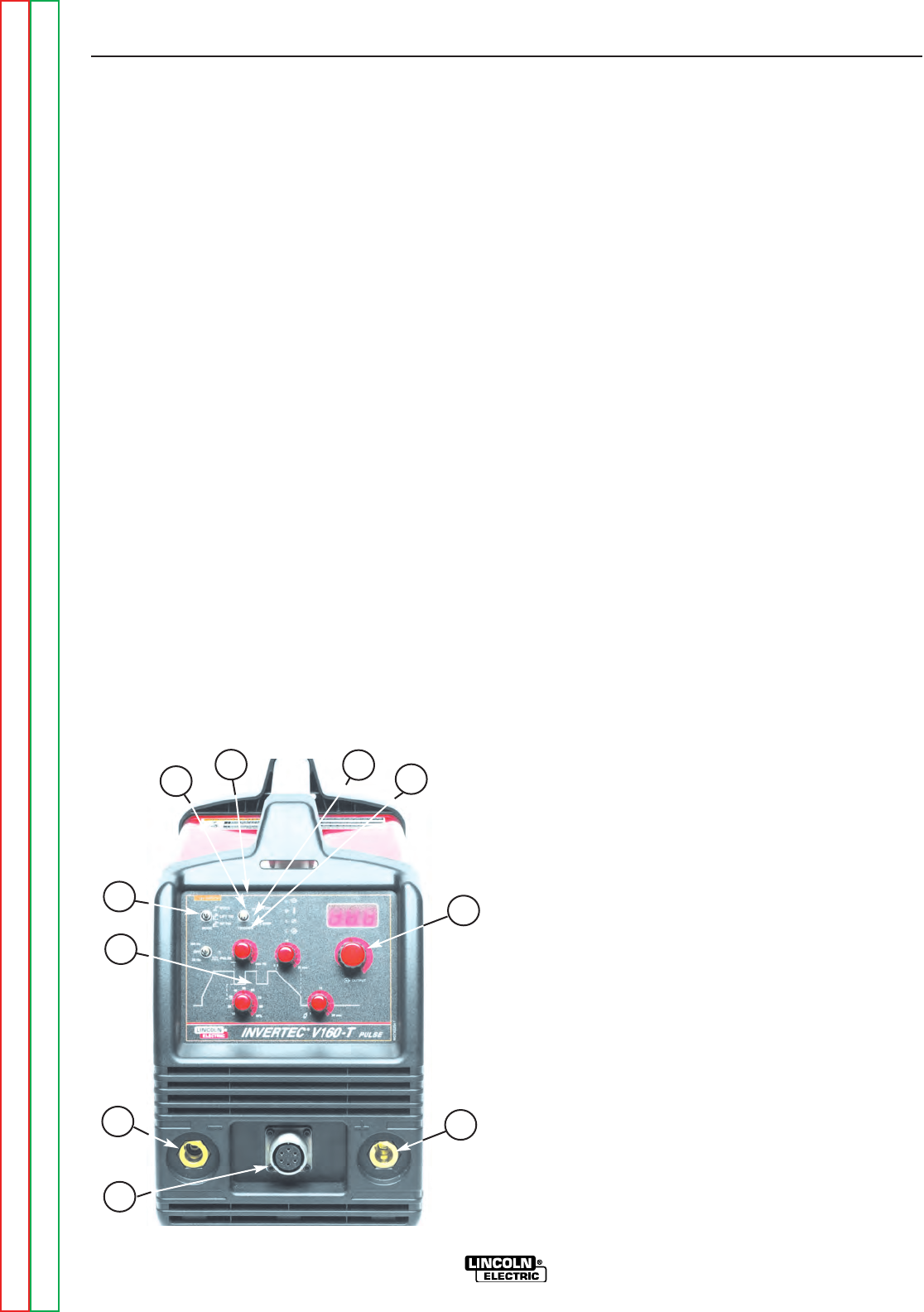

3. Mode Switch

4. Arc Control

5. Power LED

6. Thermal LED

7 Remote LED

8. Output LED

9. Output Current Control

10. Electrode Connection (Negative)

11. Remote Control Connector

12. Electrode Connection (Positive)

9. Output Current Control: This controls the output or

welding current of the machine.

The function of this control knob is changed if a

remote control is connected. If the Remote LED is

ON, this indicates that a remote control is connected

and the function of the output current control will be:

• Stick Welding Mode: The remote control will adjust

the output current of the machine from 5 to 160A.

The output current control knob on the display panel

is not used.

• TIG Welding Modes: The maximum output current of

the machine is set by the output current control knob.

The remote control then adjusts the output current

from the minimum output (5A) to the value set by the

output current control knob. For example, if the out-

put current control knob on the machine is set to

100A then the remote control will adjust the output

current from a minimum of 5A to a maximum of

100A.

10. “Twist-Mate” Connection (Negative):

11. Remote Control Connector:

12. “Twist-Mate” Connection (Positive):

FIGURE B.2

4

3

5

7

8

9

12

10

11

6