OPERATION

BB-10 BB-10

V160-S & -T

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

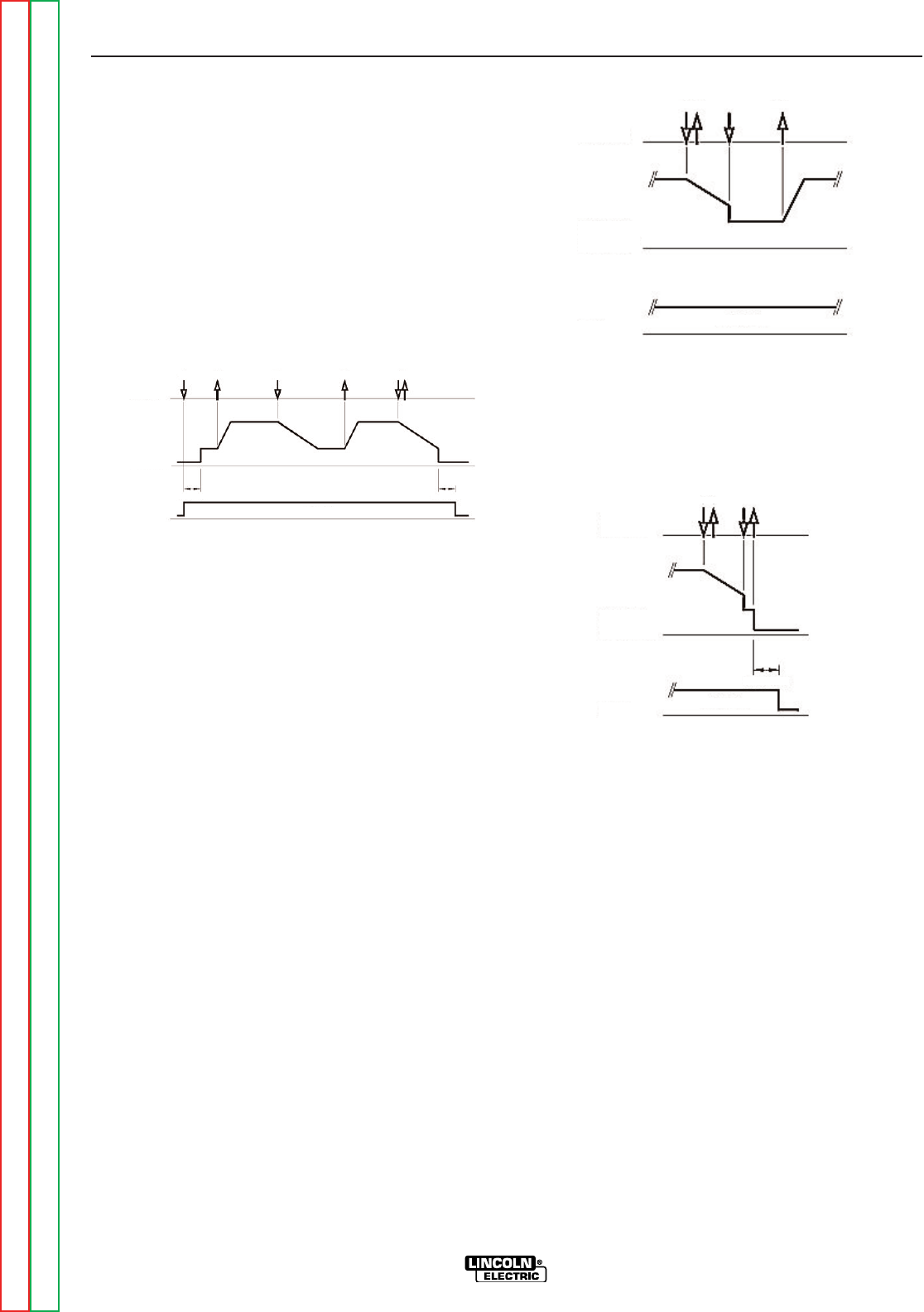

4-Step Restart Enabled (DIP Switch 4 = ON)

Same as step 1.

Same as step 2.

3. Press and hold the TIG torch trigger when the main

part of the weld is complete. The machine will now

decrease the output current at a controlled rate

(downslope), until the Start/Crater current is

reached. This Start/Crater current can be main-

tained as long or as short as necessary.

FIGURE BB.10

This sequence has an automatic restart so welding

will continue after this step. If the weld is complete-

ly finished, use the following sequence instead of

step 3 described above.

3A. Quickly press and release the TIG torch trigger.

The machine will now decrease the output current

at a controlled rate (downslope), until the

Start/Crater current is reached and the output of

the machine is turned OFF. After the arc is turned

OFF the postflow time will start.

4. Release the TIG torch trigger. The output current

will again increase (upslope) to the welding current,

like in step 2, to continue welding. When the main

part of the weld is complete go to step 3.

As shown in figure BB.11, after the TIG torch trigger

is quickly pressed and released from step 3A, it is

possible to press and hold the TIG torch trigger

another time to end the downslope time and main-

tain the output current at the Start/Crater current.

When the TIG torch trigger is released the output

will again increase (upslope) to the welding current,

like in step 4, to continue welding. When the main

part of the weld is complete go to step 3.

FIGURE BB.11

As shown in figure BB.12, again after the TIG torch

trigger is quickly pressed and released from step 3A,

it is possible to quickly press and release the TIG

torch trigger a second time to end the downslope

time and stop welding.

FIGURE BB.12

TORCH

BUTTON

OUTPUT

CURRENT

G

AS

––GAS ON––

P

OST-FLOW

POST-FLOW

(1) (3A)

(4)

(3)

(2)

TORCH

B

UTTON

O

UTPUT

CURRENT

GAS

––GAS ON––

(3A)

(

4)

TORCH

BUTTON

OUTPUT

CURRENT

GAS

––GAS ON––

(3A)

POST-FLOW