OPERATION

BB-12 BB-12

V160-S & -T

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

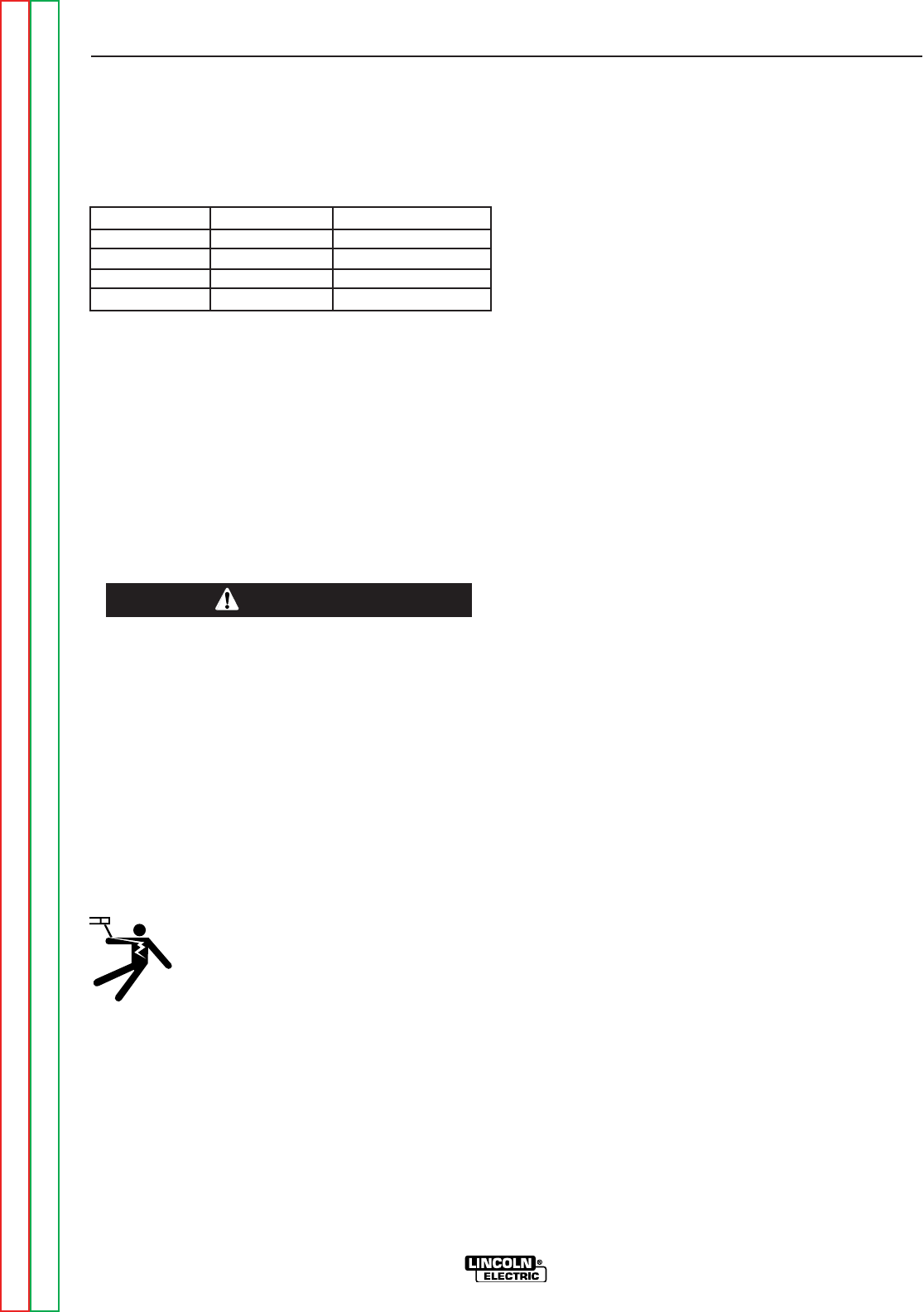

DIP Switch 7 & 8: Upslope Timer

These control the upslope timer for TIG welding (used

only on "T" type machines). The following table

shows the DIP Switch settings and selected upslope

time.

DIP Switch 7 DIP Switch 8 Upslope Time

ON ON 0.1 seconds

OFF OFF 0.5 seconds

ON OFF 1 second

OFF ON 4 seconds

Start/Crater Current Adjustment

The start/crater current of a "T" type machine can be

changed if necessary. The values are set from the fac-

tory.

European Machines:

20% (160A welding current = 32A start/crater current)

USA Machines:

10% (160A welding current = 16A start/crater current)

Be sure that all installation, operation, mainte-

nance and repair procedures are performed only

by qualified individuals. Lincoln Electric is not

responsible for damages caused by improper

installation, improper care or abnormal operation.

This adjustment procedure must be performed

only by Lincoln trained service technicians. The

machine will be operating with the cover removed

where it is possible to come in contact with high

voltages. Read all the following instructions

before starting the procedure.

ELECTRIC SHOCK CAN KILL:

• Welding equipment generates high

voltages.

• Do not touch the live parts of the

machine, the electrode, the work

clamp, or connected work pieces

when this equipment is on.

• Insulate yourself from live electrical connec-

tions, the electrode, the work clamp, and the

connected work pieces.

-----------------------------------------------------------------------

1. Remove the cover of the machine to access the

control Printed Circuit Boards on the case front.

2. To adjust the start/crater current, output current from

the machine must flow through a load bank or a TIG

arc. Connect the necessary equipment. In both

cases, load bank or TIG arc, a trigger must be con-

nected to the machine. If a load bank is used, it must

be setup for 160A and approximately 25V.

3. Make sure all electrical connections are free from

contact with other parts of the machine. Reconnect

the case back if necessary. Turn ON the machine.

4. On the control panel of the machine, select the fol-

lowing:

• Mode Switch: LIFT TIG (Do not use HF TIG or dam-

age to measuring equipment will occur.)

• Trigger Mode: 4 Step

• Pulsing: OFF

• Output Current: Maximum (160A)

5. Activate the trigger of the machine to achieve the

start or crater current portion of the welding

sequence. Refer to the trigger sequences explained

above if more information is needed.

6. In this condition, measure the output current of the

machine and adjust the start/crater current as nec-

essary. The calibration trimmer for the start/crater

current is located on the left side of the machine (as

viewed from the front) on the display board. The

access hole for this trimmer is the higher one on the

display board. (Do not adjust the lower trimmer on

the display board; this is the output current calibra-

tion.)

The output current is set to 160A, therefore the

start/crater current calibration will be a percentage

of this 160A setting. Use the following equation for

determining the desired start/crater current calibra-

tion:

Desired start/crater current percentage multiplied

by 160 = calibration current.

For example, to calibrate the machine for 15%

start/crater current, multiply this by 160 to get the

calibration current ( 0.15 x 160 = 24).

7. Release the trigger to turn off the output of the

machine. Turn OFF the machine and disconnect it

from the input source. Reassemble the machine

making sure the ground wire to the cover is con-

nected.

WARNING