Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

THEORY OF OPERATION

E-4 E-4

V160-S & -T

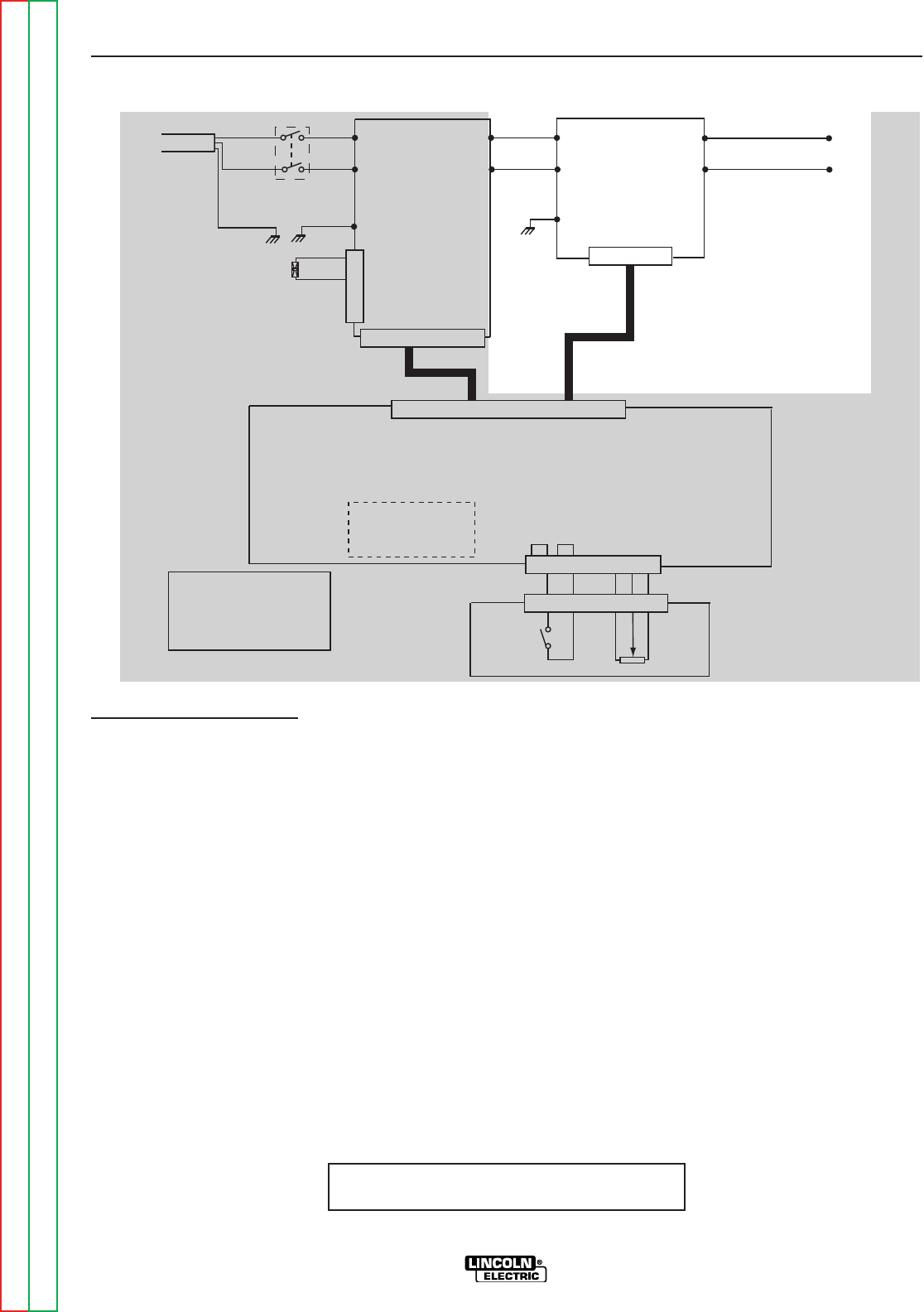

FIGURE E.4 – INVERTER BOARD

INVERTER BOARD

W05X0190

(SCHEMATIC X0190)

GND

DC-

DC+

W1

W2

INPUT BOARD

W05X0250

(SCHEMATIC X0203)

Y/G

BLACK

RED

W1DC-DC-

+

-

JP1

JP1

JP2

GND

AC2

AC1

BROWN

BLUE

BLACK

WHITE

S1

1

3

4

2

DC+

DC-A

115/230/1/50/60

Vac

GREEN

FAN

J1

WELD CONTROLLER

W05X0233

(SCHEMATIC X0233)

DISPLAY BOARD

W05X0245

(SCHEMATIC X0245)

JP1

CW

REMOTE

CONNECTOR

WARNING HIGH VOLTAGE CAN KILL

• Do not operate with coers removed.

• Disconnect input power by unplugging

powercordbefore servicing.

• Do not touch electrically live parts.

• Only qualified persons should install,

use or service this machine

1

2

3

6

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1 2 3 4 5 6 7 8 9 10

26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

1 2 3 4 5 6 7 8

D E C B A

INVERTER BOARD

The inverter board includes the following circuits:

- Inverter circuit: Transforms the DC current at 80KHz

and feeds the main transformer. The current is regu-

lated via Pulse Width Modulation

- Main transformer: It has two functions:

1) gives the correct output voltage for welding

2) Insulates the operator side from the output

line

- Output circuit: The output diodes rectify the output

the current from the main transformer. The choke fil-

ters the output current.The shunt provides output

feedback information to the control board.

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion