APPENDIX

111

Appendix4 Instructions for UL and cUL

(Standard to comply with: UL 508C, CSA C22.2 No.14)

General Precaution

CAUTION - Risk of Electric Shock -

The bus capacitor discharge time is 10 minutes. Before starting wiring or inspection, switch power off, wait for more than 10 minutes, and check for residual

voltage between terminal P/+ and N/- with a meter etc., to avoid a hazard of electrical shock.

ATTENTION - Risque de choc électrique -

La durée de décharge du condensateur de bus est de 10 minutes. Avant de commencer le câblage ou l’inspection, mettez l’appareil hors tension et attendez plus

de 10 minutes.

Installation

The FR-A802 inverters with the below types of converter unit have been approved as products for use in enclosure.

Design the enclosure so that the surrounding air temperature, humidity and ambience of the inverter will satisfy the above specifications. (Refer to page 17.)

Wiring protection

For installation in the United States, Class T, Class J, Class CC, or Class L fuse must be provided, in accordance with the National Electrical Code and any

applicable local codes.

For installation in Canada, Class T, Class J, Class CC, or Class L fuse must be provided, in accordance with the Canadian Electrical Code and any applicable

local codes.

Maximum allowable rating by US National Electrical Code. Exact size must be chosen for each installation.

Wiring to the power supply and the motor

For wiring the input (R/L1, S/L2, T/L3) terminals of the converter unit and output (U, V, W) terminals of the inverter, use the UL listed copper, stranded wires (rated

at 75°C) and round crimping terminals. Crimp the crimping terminals with the crimping tool recommended by the terminal maker.

Short circuit ratings

Suitable For Use in A Circuit Capable of Delivering Not More Than 100 kA rms Symmetrical Amperes, 550 V or 600 V Maximum.

Motor overload protection

When using the electronic thermal relay function as motor overload protection, set the rated motor current in Pr.9 Electronic thermal O/L relay.

NOTE

• The internal accumulated heat value of the electronic thermal relay function is reset by inverter power reset and reset signal input. Avoid unnecessary reset and power-

OFF.

• Install an external thermal relay (OCR) between the inverter and motors to operate several motors, a multi-pole motor or a dedicated motor with one inverter. Note that

the current indicated on the motor rating plate is affected by the line-to-line leakage current (refer to Instruction Manual (Detailed)) when selecting the setting for an

external thermal relay.

• The cooling effect of the motor drops during low-speed operation. Use a thermal protector or a motor with built-in thermistor.

• When the difference between the inverter and motor capacities is large and the setting is small, the protective characteristics of the electronic thermal relay function will

be deteriorated. In such case, use an external thermal relay.

• A dedicated motor cannot be protected by an electronic thermal O/L relay. Use an external thermal relay.

• If the electronic thermal O/L relay is set to 5% or lower of the rated inverter current, the electronic thermal O/L relay may not operate.

• Motor over temperature sensing is not provided by the drive.

FR-CC2-[ ] H315K H355K H400K H450K H500K

Rated fuse voltage (V) 500 V or more

Fuse maximum allowable rating (A)

1100 1200 1350 1500 1800

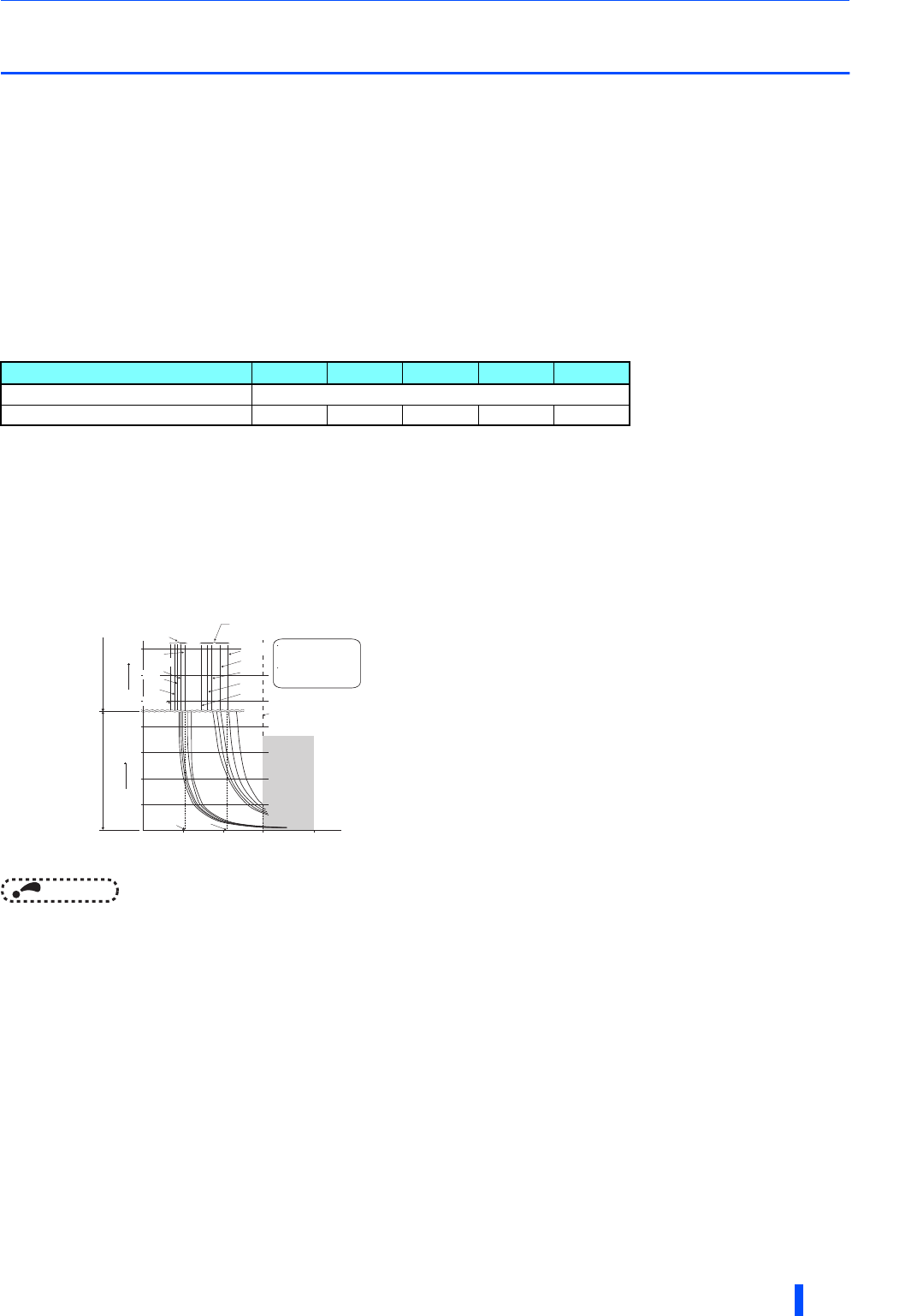

Operation characteristics of electronic thermal relay function

This function detects the overload (overheat) of the motor and trips the

inverter by stopping the operation of the transistor at the inverter output side.

(The operation characteristic is shown on the left.)

• Mitsubishi constant-torque motor

(1) Set one of "1", "13" to "16" in Pr.71. (This setting will enable the 100%

constant-torque characteristic in the low-speed range.)

(2) Set the rated current of the motor in Pr.9.

When a value 50% of the inverter rated output current (current value)

is set in Pr.9

The % value denotes the percentage to the rated inverter current. It is

not the percentage to the rated motor current.

When you set the electronic thermal relay function dedicated to the

Mitsubishi constant-torque motor, this characteristic curve applies to

operation at 6 Hz or higher.

Transistor protection is activated depending on the temperature of the

heatsink. The protection may be activated even with less than 150%

depending on the operating conditions.

230

52.5%

105%

50

100

150

60

120

180

240

50

60

70

Pr.9 = 50% setting

of inverter rating

∗1, 2

Pr.9 = 100% setting

of inverter rating

∗2

6Hz

20Hz

10Hz

6Hz

0.5Hz

30Hz

or more

∗3

30Hz

or more

∗3

20Hz

10Hz

0.5Hz

Range for

the transistor

protection

∗4

(s) unit display in this region

(min) unit display in

this region

Operation time (min)Operation time (s)

Characteristic when

electronic thermal relay

function for motor

protection is turned off

(When

Pr.9

setting is 0(A))

Inverter output power (%)

(% to the inverter rated current)

Operation region

Region on the right of

characteristic curve

Non-operation region

Region on the left of

characteristic curve