Installation of the inverter and enclosure design

INSTALLATION AND WIRING

19

2

2.3.2 Cooling system types for inverter enclosure

From the enclosure that contains the inverter, the heat of the inverter and other equipment (transformers, lamps, resistors,

etc.) and the incoming heat such as direct sunlight must be dissipated to keep the in-enclosure temperature lower than the

permissible temperatures of the in-enclosure equipment including the inverter.

The cooling systems are classified as follows in terms of the cooling calculation method.

(a) Cooling by natural heat dissipation from the enclosure surface (totally enclosed type)

(b) Cooling by heatsink (aluminum fin, etc.)

(c) Cooling by ventilation (forced ventilation type, pipe ventilation type)

(d) Cooling by heat exchanger or cooler (heat pipe, cooler, etc.)

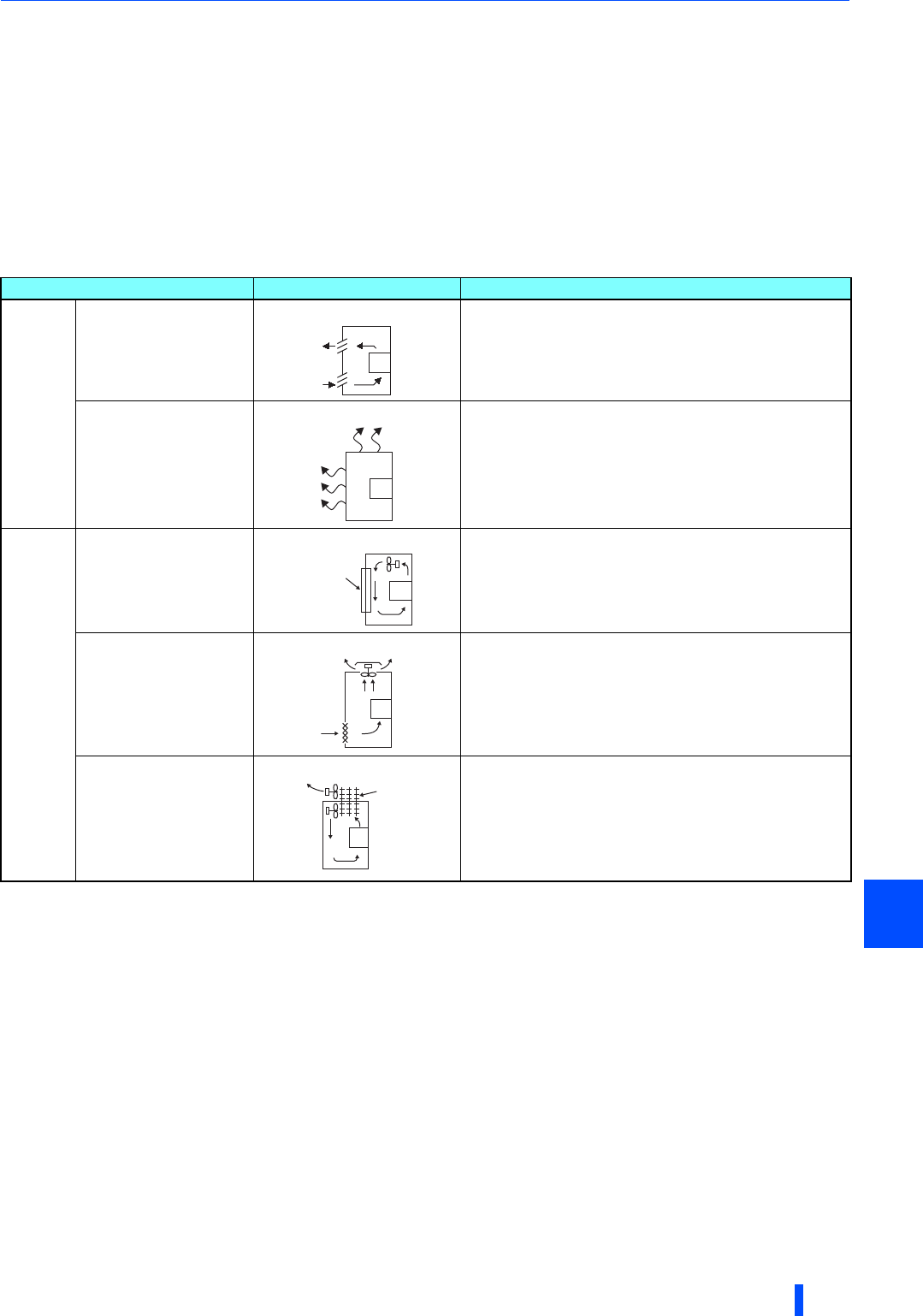

Cooling system Enclosure structure Comment

Natural

cooling

Natural ventilation

(enclosed, open type)

This system is low in cost and generally used, but the

enclosure size increases as the inverter capacity increases.

This system is for relatively small capacities.

Natural ventilation (totally

enclosed type)

Being a totally enclosed type, this system is the most

appropriate for hostile environment having dust, dirt, oil mist,

etc. The enclosure size increases depending on the inverter

capacity.

Forced

cooling

Heatsink cooling

This system has restrictions on the heatsink mounting position

and area. This system is for relatively small capacities.

Forced ventilation

This system is for general indoor installation. This is

appropriate for enclosure downsizing and cost reduction, and

often used.

Heat pipe This is a totally enclosed for enclosure downsizing.

INV

INV

INV

Heatsink

INV

INV

Heat

pipe