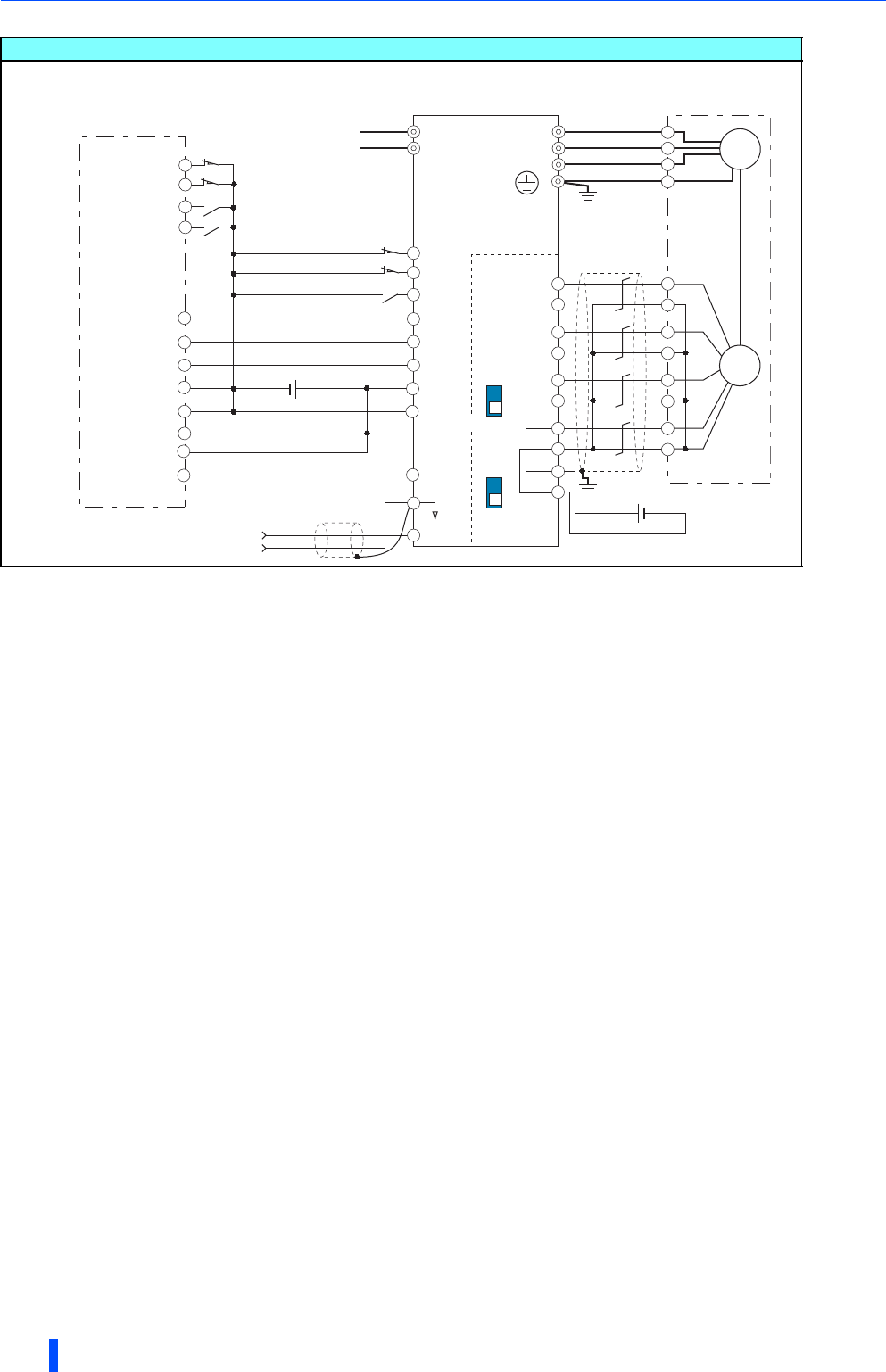

Connection of motor with encoder (vector control)

54

INSTALLATION AND WIRING

• Position control

Vector control dedicated motor, 12 V complementary

The pin number differs according to the encoder used.

Speed, control, torque control, and position control by pulse train input are available with or without the Z-phase being

connected.

Connect the encoder so that there is no looseness between the motor and motor shaft. Speed ratio must be 1:1.

Earth (ground) the shield of the encoder cable to the enclosure using a tool such as a P-clip. (Refer to page 55.)

For the complementary, set the terminating resistor selection switch to OFF position. (Refer to page 51.)

A separate power supply of 5 V / 12 V / 15 V / 24 V is necessary according to the encoder power specification.

When the encoder output is the differential line driver type, only 5 V can be input.

Make the voltage of the external power supply the same as the encoder output voltage, and connect the external

power supply between PG and SD.

For terminal compatibility of the FR-JCBL, FR-V7CBL, and FR-A8AP, refer to page 53.

Assign the function using Pr.178 to Pr.184, Pr.187 to Pr.189 (input terminal function selection).

When position control is selected, terminal JOG function is invalid and simple position pulse train input terminal

becomes valid.

Assign the function using Pr.190 to Pr.194 (output terminal function selection).

Vector control

dedicated motor

Torque limit command

(±10V)

1

5

(+)

(-)

∗4 ∗6

∗3

PA1

FR-A8AP

PA2

PB1

PB2

PZ1

PZ2

PG

PG

SD

SD

Forward stroke end

Reverse stroke end

Pre-excitation/servo on

Clear signal

Pulse train

Sign signal

Preparation ready signal

STF

STR

LX

∗7

CLR ∗7

CLEAR

JOG

∗8

NP ∗7

∗1

Differential

line driver

Terminating

resistor

ON

OFF

U

V

W

U

V

W

E

A

Earth

(ground)

∗2

B

C

D

F

G

S

R

IM

PLG

Inverter

Positioning unit

MELSEC-Q QD75P[]N/QD75P[]

MELSEC-L LD75P[]

12VDC

power supply

(+)

(-)

∗5

PULSE F

PULSE R

PULSE COM

CLRCOM

RDYCOM

READY

PC

RDY ∗9

SE

FLS

RLS

DOG

STOP

COM

24VDC power supply

Complementary

P/+

N/-

To converter unit