Connection of motor with encoder (vector control)

INSTALLATION AND WIRING

55

2

Instructions for encoder cable wiring

• Use shielded twisted pair cables (0.2 mm

2

or larger) to connect the FR-A8AP. For the wiring to the terminals PG and SD,

use several cables in parallel or use a thick cable, according to the wiring length.

To protect the cables from noise, run them away from any source of noise (such as the main circuit and power supply

voltage).

When differential line driver is set and a wiring length is 30 m or more.

The wiring length can be extended to 100 m by increasing the 5 V power supply (approximately to 5.5 V) while using six or more 0.2 mm

2

gauge

cables in parallel or a 1.25 mm

2

or larger gauge cable. The voltage applied must be within power supply specifications of encoder.

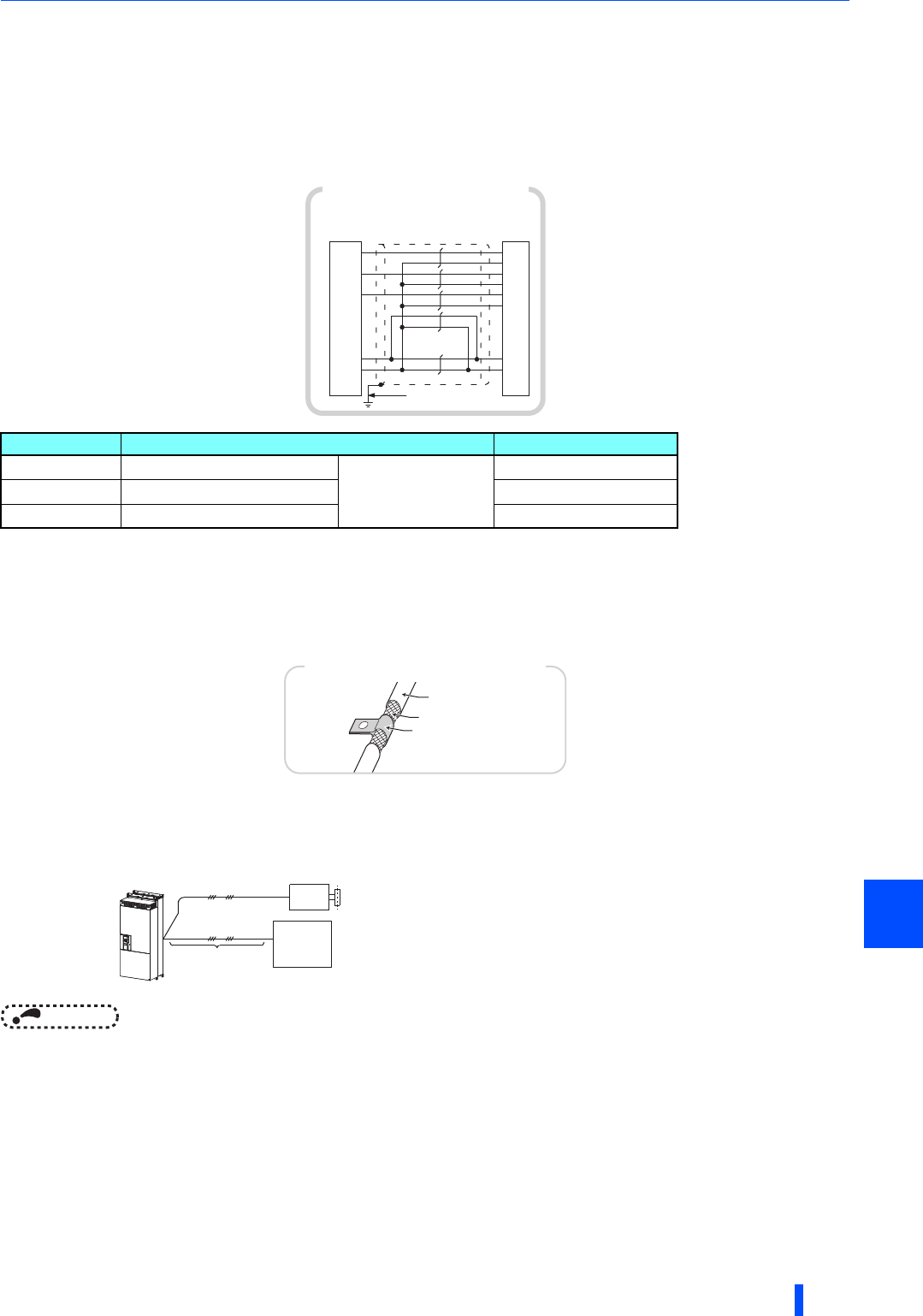

• To reduce noise of the encoder cable, earth (ground) the encoder's shielded cable to the enclosure

(as close as possible to the inverter) with a P-clip or U-clip made of metal.

• When one encoder is shared between FR-A8AP and CNC (computerized numerical controller), its output signal should be

connected as shown below. In this case, the wiring length between FR-A8AP and CNC should be as short as possible,

within 5 m.

NOTE

• For the details of the optional encoder dedicated cable (FR-JCBL/FR-V7CBL), refer to page 52.

• The FR-V7CBL is provided with a P-clip for earthing (grounding) shielded cables.

Wiring length Parallel connection Larger-size cable

Within 10 m At least two cables in parallel

Cable gauge 0.2 mm

2

0.4 mm

2

or larger

Within 20 m At least four cables in parallel

0.75 mm

2

or larger

Within 100 m

At least six cables in parallel

1.25 mm

2

or larger

PZ2

PZ1

PA1

PA2

FB1

FB2

SD

PG

G

F

D

C

B

A

R

S

Encoder

2 mm

2

FR-A800

(FR-A8AP)

Example of parallel connection

with two cables

(with complementary encoder output)

Encoder cable

Shield

P-clip

Earthing (grounding) example using a P-clip

NC

Maximum 5 m

(two parallel cables)

Inverter

(FR-A8AP)

Encoder