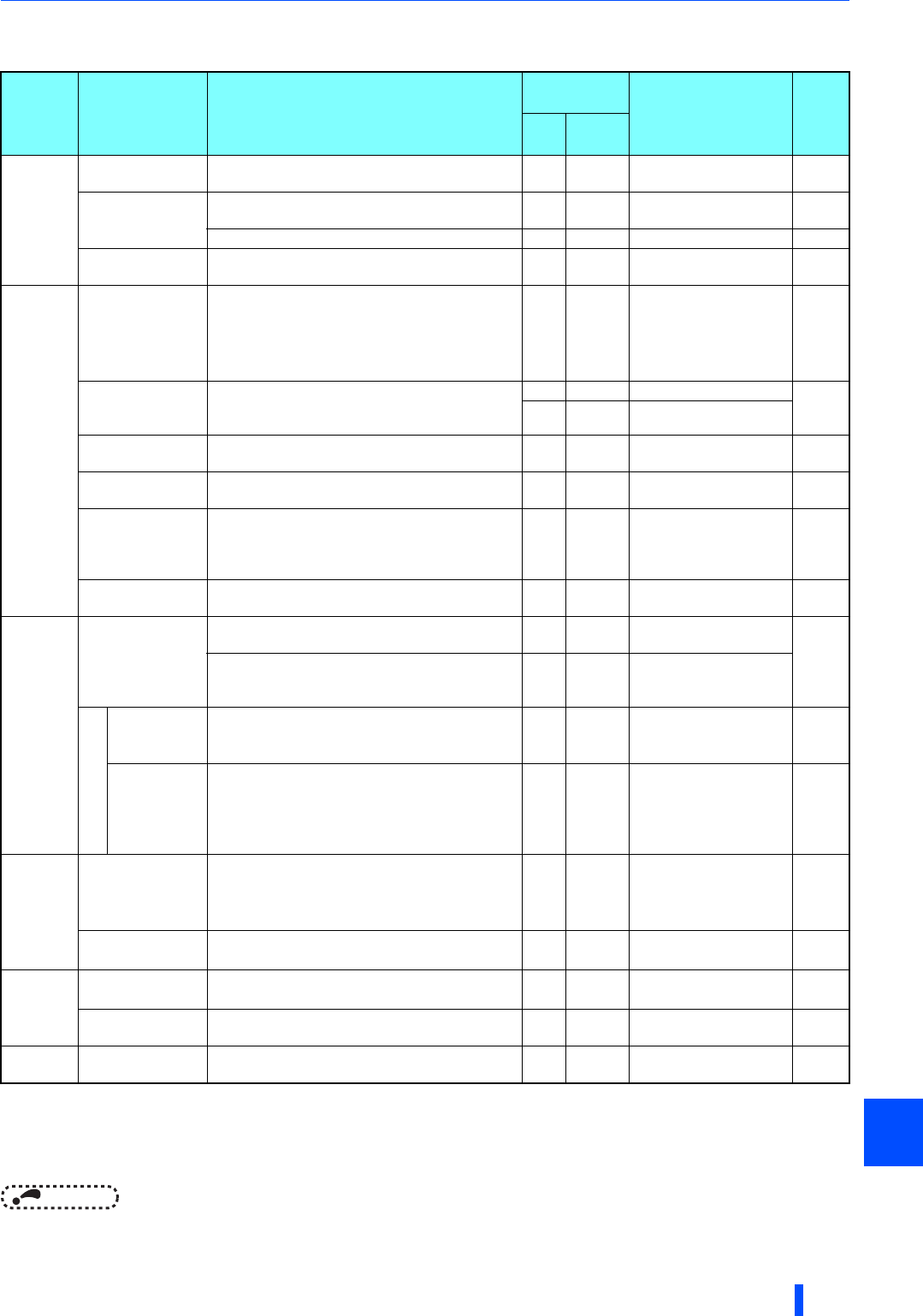

Inspection item

PRECAUTIONS FOR MAINTENANCE AND INSPECTION

87

5

5.1.3 Daily and periodic inspection

Oil component of the heat dissipation grease used inside the inverter may leak out. The oil component, however, is not flammable, corrosive, nor

conductive and is not harmful to humans. Wipe off such oil component.

It is recommended to install a voltage monitoring device for checking the voltage of the power supplied to the inverter.

One to two years of periodic inspection cycle is recommended. However, it differs according to the installation environment.

Consult us for periodic inspection.

NOTE

• Continuous use of a leaked, deformed, or degraded smoothing aluminum electrolytic capacitor (as shown in the table above)

may lead to a burst, breakage or fire. Replace such capacitor without delay.

Area of

inspection

Inspection item Description

Inspection

interval

Corrective action at

fault occurrence

Check

by the

user

Daily

Periodic

General

Surrounding

environment

Check the surrounding air temperature, humidity,

dirt, corrosive gas, oil mist, etc.

Improve the environment.

Overall unit

Check for unusual vibration and noise.

Check fault location and

retighten.

Check for dirt, oil, and other foreign material.

Clean.

Power supply

voltage

Check that the main circuit voltages and control

voltages are normal.

Inspect the power supply.

Main circuit

General

(1) Check with megger (across main circuit

terminals and earth (ground) terminal).

Contact the manufacturer.

(2) Check for loose screws and bolts. Retighten.

(3) Check for overheat traces on the parts. Contact the manufacturer.

(4) Check for stain. Clean.

Conductors, cables

(1) Check conductors for distortion.

(2) Check cable sheaths for breakage and

deterioration (crack, discoloration, etc.).

Contact the manufacturer.

Contact the manufacturer.

Transformer/

reactor

Check for unusual odor and abnormal increase of

whining sound.

Stop the equipment and

contact the manufacturer.

Terminal block Check for a damage.

Stop the equipment and

contact the manufacturer.

Smoothing

aluminum

electrolytic

capacitor

(1) Check for liquid leakage. Contact the manufacturer.

(2) Check for safety valve projection and bulge. Contact the manufacturer.

(3) Judge by visual check

Relay/contactor

Check that the operation is normal and no

chattering sound is heard.

Contact the manufacturer.

Control

circuit,

protective

circuit

Operation check

(1) Check that the output voltages across phases

are balanced while operating the inverter alone.

Contact the manufacturer.

(2) Check that no fault is found in protective and

display circuits in a sequence protective

operation test.

Contact the manufacturer.

Components check

Overall

(1) Check for unusual odor and discoloration.

Stop the equipment and

contact the manufacturer.

(2) Check for serious rust development. Contact the manufacturer.

Aluminum

electrolytic

capacitor

(1) Check for liquid leakage in a capacitor and

deformation trace.

Contact the manufacturer.

(2) Visual check and judge by the life check of the

control circuit capacitor. (Refer to the FR-A800

Instruction Manual (Detailed)).

Cooling

system

Cooling fan

(1) Check for unusual vibration and noise. Replace the fan.

(2) Check for loose screws and bolts.

Fix with the fan cover

fixing screws

(3) Check for stain. Clean.

Heatsink

(1) Check for clogging. Clean.

(2) Check for stain. Clean.

Display

Indication

(1) Check that display is normal. Contact the manufacturer.

(2) Check for stain. Clean.

Meter Check that reading is normal.

Stop the equipment and

contact the manufacturer.

Load

motor

Operation check

Check for vibration and abnormal increase in

operation noise.

Stop the equipment and

contact the manufacturer.