37

8. INSTRUMENT MAINTENANCE

8.1. Maintenance Schedule

There is no Internal IZS offered for the T100H.

8.2. Predictive Diagnostics

Because the T100H’s internal pneumatics are monitored in a different manner than those of the T100 there are

some differences in how the instrument’s test functions are used as predictive diagnostics. Table 8-1 of this

addendum supersedes Table 9-2 of the T100 Manual

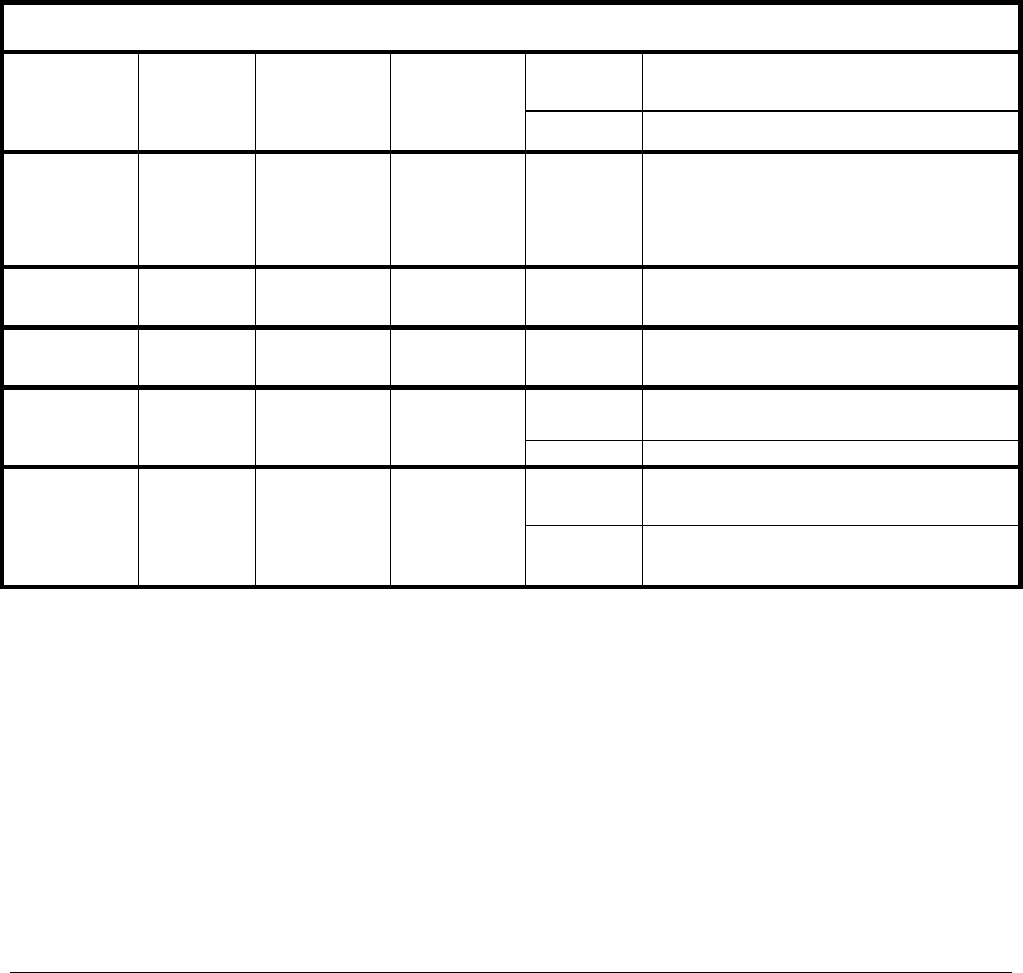

Table 8-1: Predictive Uses for Test Functions

BEHAVIOR TEST

FUNCTION

DAS

FUNCTION

CONDITION

EXPECTED ACTUAL

INTERPRETATION

Slowly

increasing

Flow path is clogging up.

- Check critical flow orifice & sintered filter.

- Replace particulate filter

PRES SMPPRS

Sample gas

pressure

upstream of the

critical flow

orifice.

Constant within

atmospheric

changes

Slowly

decreasing

Developing leak in pneumatic system to vacuum

(developing valve failure)

VAC VACUUM

Gas pressure

downstream of

the critical flow

orifice (e.g.

inside reaction

cell.

Constant within

atmospheric

changes

Fluctuating

Developing leak in pneumatic system

SAMP FL SMPFLW

Standard

Operation

Stable

Slowly

Decreasing

Flow path is clogging up.

- Check critical flow orifice & sintered filter.

- Replace particulate filter

DRK PMT DRKPMT

PMT output

when UV Lamp

pulses off

Constant within

±20 of check-

out value

Significantly

increasing

PMT cooler failure

Decreasing

over time

Drift of instrument response; UV Lamp output is

excessively low.

SO

2

Concentration

CONC1

Standard

configuration at

span

stable for

constant

concentration

Fluctuating

Leak in gas flow path.

Fluctuating

or Slowly

increasing

UV detector wearing out

UV source Filter developing pin holes

LAMP RATIO LAMPR

Standard

Operation

Stable and near

100%

Slowly

deceasing

UV detector wearing out

Opaque oxides building up on UV source Filter

UV lamp aging

07265A DCN6038