Teledyne API - T100H Addendum to T100 Operation Manual Theory Of Operation

41

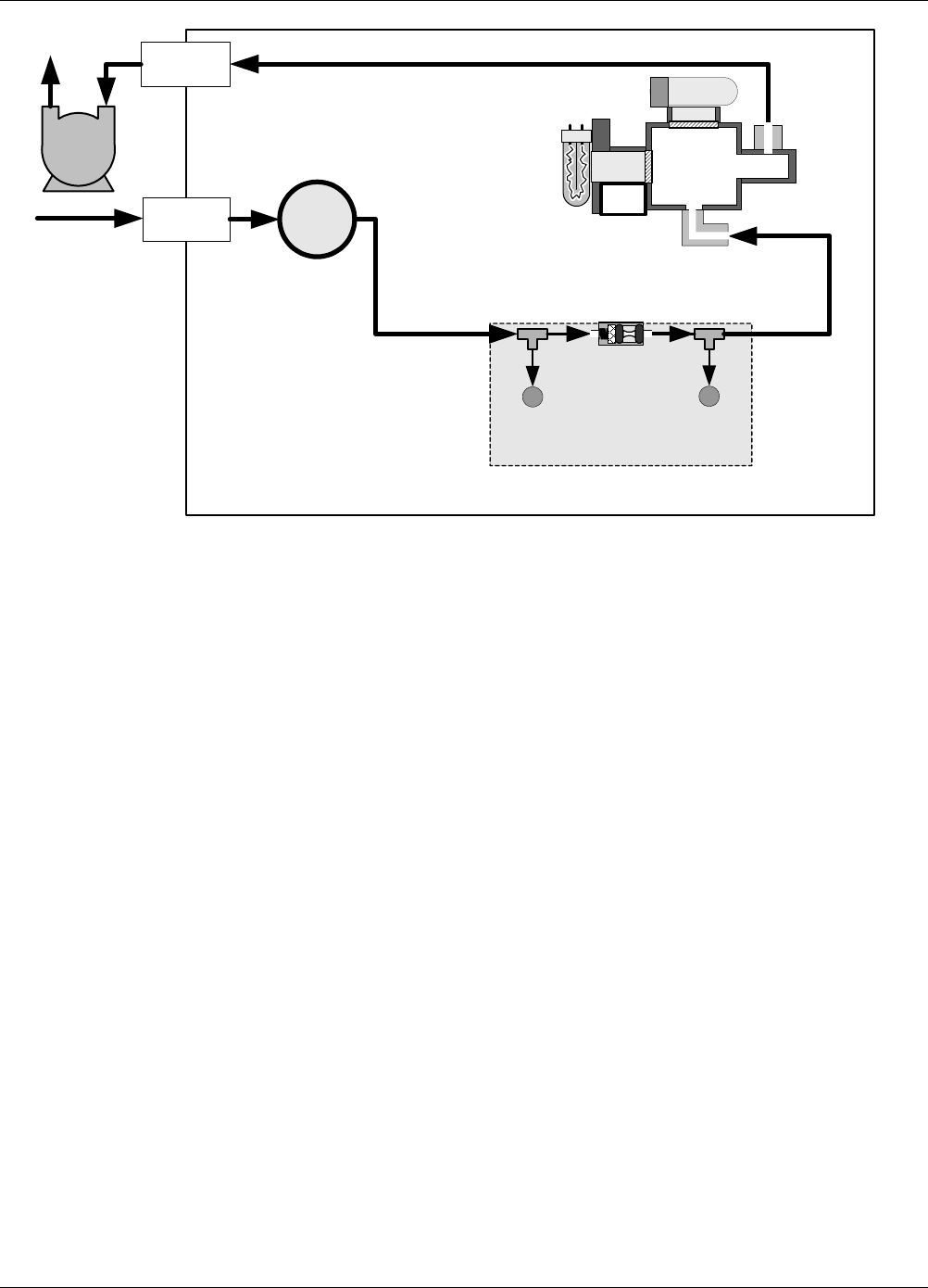

FLOW CONTROL &

PRESSURE SENSOR

VACUUM

PRESSURE

SENSOR

SAMPLE

PRESSURE

SENSOR

CRITICAL

FLOW ORIFICE

700 cm

3

/min

@ 7 In-Hg-A

Particulate

Filter

PUMP

EXHAUST

GAS OUTLET

SAMPLE

GAS INLET

INSTRUMENT CHASSIS

UV

LAMP

PMT

REACTION

CELL

UV

Detector

Figure 9-2: Pneumatic Diagram of the T100H – Base Configuration

9.2.2. Pneumatic Sensors

The T100H uses two pneumatic sensors to verify gas flow. These sensors are located on a printed circuit

assembly, called the pneumatic pressure/flow sensor board. This PCA is attached to a manifold containing the

critical flow orifice that sets the instrument flow rate.

9.2.2.1. Sample Pressure Sensor

An absolute pressure transducer plumbed to the input of the analyzer’s sample chamber is used to measure the

pressure of the sample gas before it passes through the critical flow orifice. This is used to validate the critical

flow condition (2:1 pressure ratio) through the instrument’s critical flow orifice.

The actual sample gas pressure measurement is viewable through the analyzer’s front panel display as the test

function PRES

9.2.2.2. Vacuum Pressure Sensor

An absolute pressure transducer measures the pressure on the vacuum side of the critical flow orifice and is

used to measure the sample gas pressure in the reaction cell. If the vacuum pressure is not in the correct

range, a warning will be displayed by the software. Also, if the temperature/pressure compensation (TPC)

feature is turned on, the output of this sensor is also used to supply pressure data for that calculation.

The actual pressure of the gas downstream from the critical flow orifice (including the gas inside the reaction

cell) viewable through the analyzer’s front panel display as the test function VAC

07265A DCN6038