45

10. TROUBLESHOOTING & REPAIR

For the most part the information contained in Section 11 of the T100 Manual (P/N 06807) is also applicable to

the T100H. There are a few exceptions however.

10.1.1. Fault Diagnosis with Warning Messages

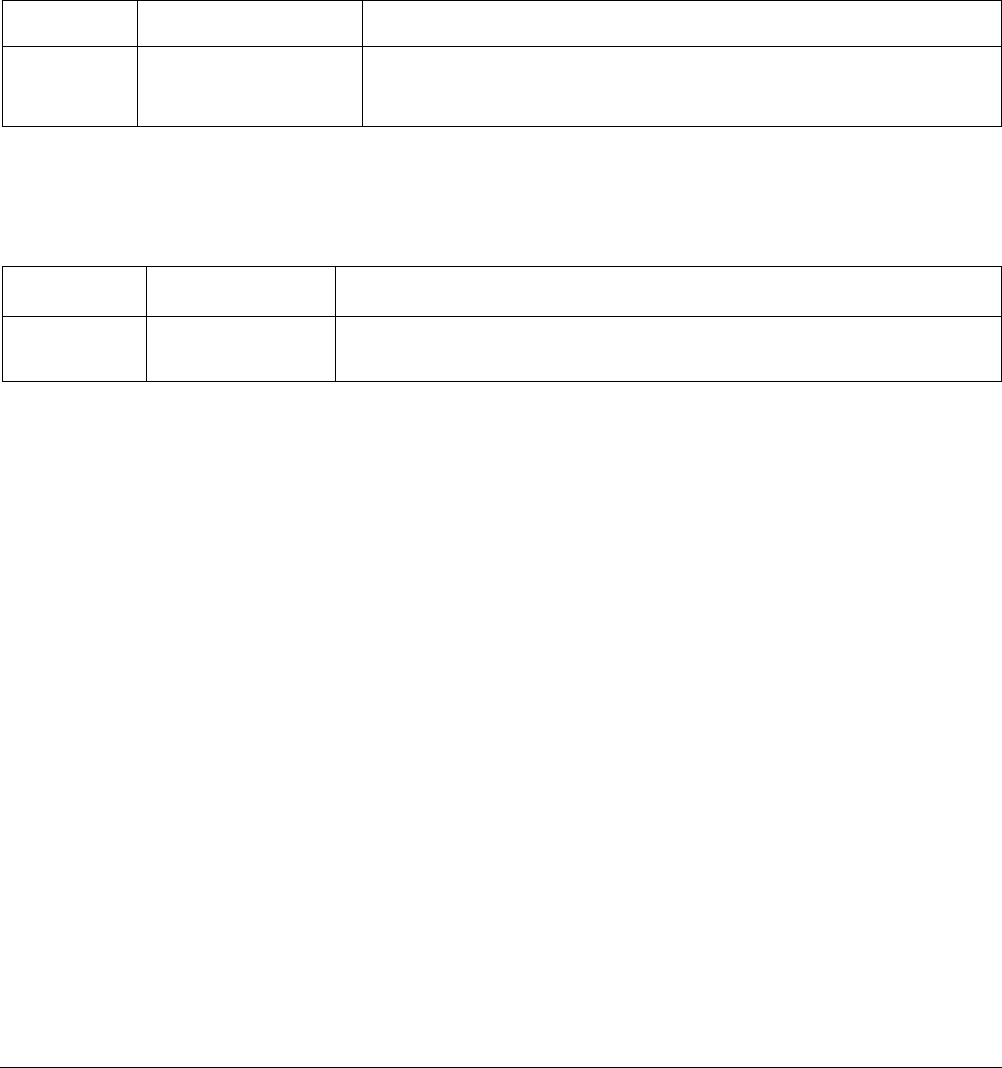

Table 10-1: Warning Messages - Indicated Failures

WARNING

MESSAGE

FAULT CONDITION POSSIBLE CAUSES

VACUUM

PRESS

WARN

Gas pressure inside the

reaction cell outside of

warning limits.

If sample pressure is > 10 in-Hg:

o Pneumatic Leak

o Bad Pump Rebuild Pump

o Failed pressure sensor/circuitry

10.1.2. Fault Diagnosis with Test Functions

Table 10-2: Test Functions - Possible Causes for Out-Of-Range Values

TEST

FUNCTION

NOMINAL

VALUE(S)

POSSIBLE CAUSE(S)

VAC

<9.1 IN-HG-A

Incorrect sample gas pressure could be due to: pneumatic leak; malfunctioning valve;

malfunctioning pump; clogged flow orifices; sample inlet overpressure; faulty pressure

sensor

10.2. Subsystem Checkout

10.2.1. Pneumatic Sensor Assembly

The pneumatic sensor assembly of the T100H differs from that of the T100 in that there is no flow sensor.

Instead the assembly includes two pressure sensors located on either side of a critical flow orifice. The T100H

software infers the gas flow rate by mathematically comparing the two pressure readings.

If you suspect that one of the two pressure sensors is failing:

1. Cap the sample inlet.

2. After a few seconds, check the VAC and PRES test functions and verify that:

The VAC value matches the PRES value to within 1 In-Hg-A, and;

Both are less than 10 in-Hg-A (i.e. under vacuum).

3. Uncap the sample inlet and unplug the pump.

4. After a few minutes, the value VAC and PRES should match within 1 In-Hg-A, and read atmospheric

pressure.

If the two sensors do not match or are significantly different from ambient atmospheric pressure, call

Teledyne Instruments customer service.

07265A DCN6038