Automating Calibration Procedures

You can automate the complete verification and adjustment procedures

outlined in this chapter if you have access to programmable test

equipment. You can program the instrument configurations specified for

each test over the remote interface. You can then enter readback

verification data into a test program and compare the results to the

appropriate test limit values.

You can also enter calibration constants from the remote interface.

Remote operation is similar to the local front-panel procedure. You can

use a computer to perform the adjustment by first selecting the required

setup. The calibration value is sent to the function generator and then

the calibration is initiated over the remote interface. The function

generator must be unsecured prior to initiating the calibration procedure.

For further detailing on programming the function generator, see

chapters 3 and 4 in the Agilent 33120A User’s Guide.

Recommended Test Equipment

The test equipment recommended for the performance verification and

adjustment procedures is listed below. If the exact instrument is not

available, use the accuracy requirements shown to select substitute

calibration standards.

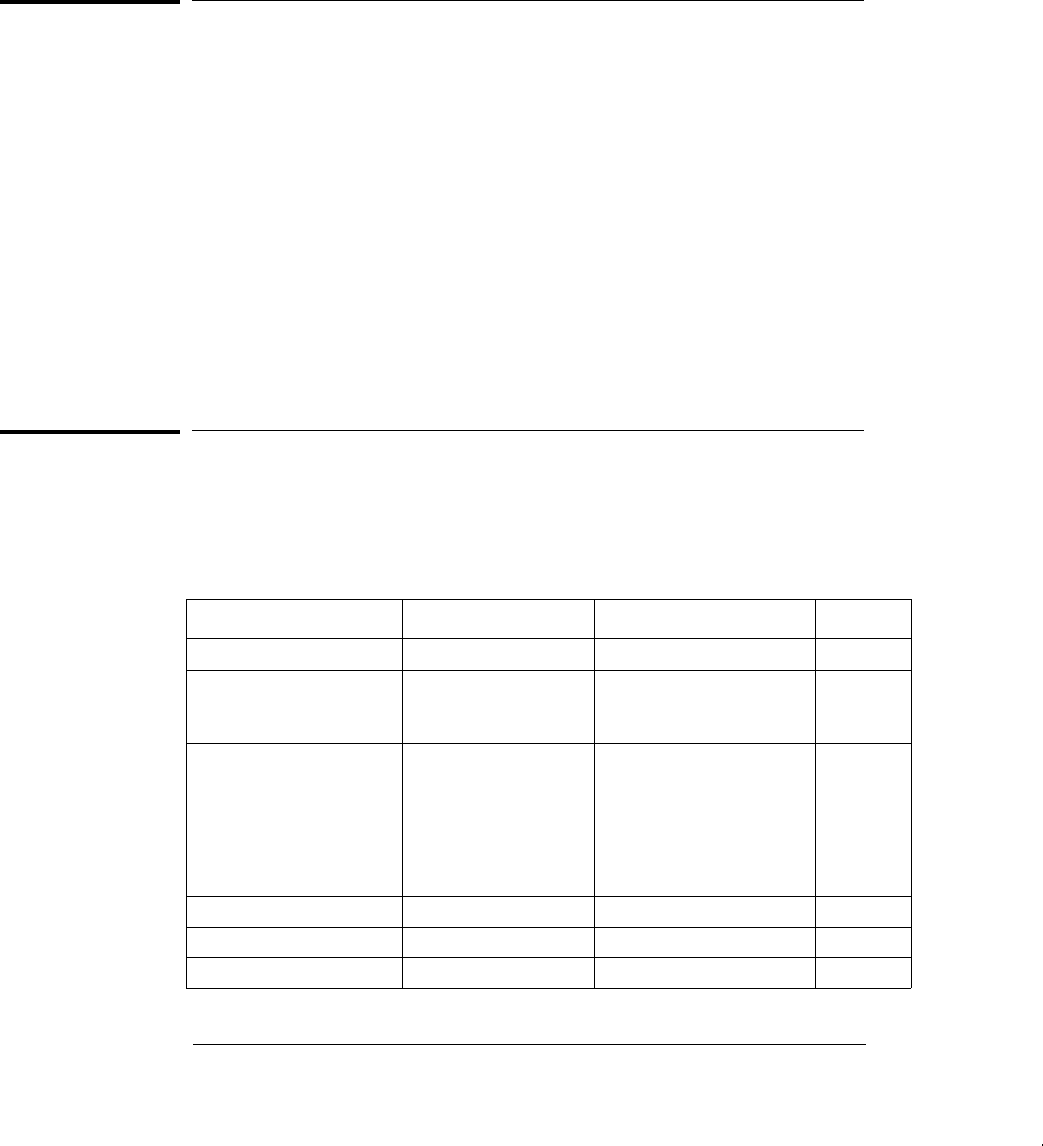

Instrument Requirements Recommended Model Use*

50 W feedthrough load 50 W 0.1 W

Q,P,O,T

6 1/2 digit Digital

Multimeter (DMM)

20 Vdc 0.01%

Integrating ACrms

10 Vacrms 0.1%

Agilent 34401A Q,P,T

Thermal Voltage Converter

(50 W termination type)

or

Power Meter

or

Wideband ACrms Meter

1kHz to 15 MHz

100 kHz to 15 MHz

1 VAC rms 0.5%

1 kHz to 20 MHz

3 Volt

Agilent E4418A with

Agilent 8482A

and 20 dB attenuator

—

Q,P

Frequency Meter 1 ppm accuracy Agilent 53131A Q,P,T

Oscilloscope 100 MHz Agilent 54624A T

Spectrum Analyzer Response to 90 MHz Agilent 8560EC O

* Q = Quick Verification O= Optional Verification Tests

P = Performance Verification Tests T = Troubleshooting

Chapter 4 Calibration Procedures

Automating Calibration Procedures

52