25

COUPLING INFORMATION

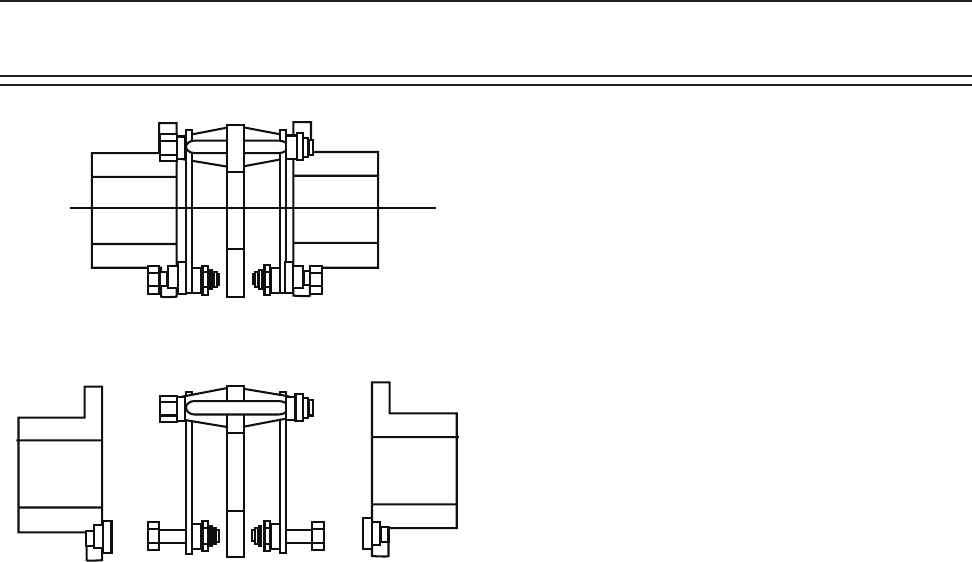

COUPLINGS INSTALLATION AND ALIGNMENT

These instructions are intended to help you to install

and align the coupling. Covered here will be general

information, hub mounting, alignment, assembly,

locknut torquing, discpack replacement, and part

numbers. The coupling as received, may or may not

be assembled.

*If assembled, the locknuts are not torqued.

*If coupling is assembled, remove the bolts that at-

tach the hubs to the disc packs. Remove both hubs.

Leave the disc packs attached to the center member.

A. Hub Mounting:

1. Clean hub bores and shafts. Remove any nicks

or burrs. If bore is tapered, check for good contact

pattern. If the bore is straight, measure the bore

and shaft diameters to assure proper t. The key(s)

should have a snug side-to-side t with a small

clearance over the top.

NOTE: If the hub position on the shaft does not allow

enough room to install the short bolts in the hub after

hub mounting, install the bolts and disc pack before

mounting hub on shaft.

B. Straight Bore:

1. Install key(s) in the shaft. If the hub is an interfer-

ence t, heat the hub in an oil bath or oven until

bore is sufciently larger than the shaft. 350º F.

is usually sufcient. An open ame is not recom-

mended. However, if ame heating is necessary,

use a very large rose bud tip to give even heat

distribution. A thermal heat stick will help deter-

mine hub temperature. DO NOT SPOT HEAT THE

HUB OR DISTORTION MAY OCCUR. With the hubs

expanded, slide it up the shaft to the desired axial

position. A pre-set axial stop device can be helpful.

C. Taper Bore:

1. Put the hub on the shaft without key(s) in place.

Lightly tap hub up the shaft with a soft hammer.

This will assure a metal-to-metal t between shaft

and hub. This is the starting point for the axial

draw. Record this position between shaft and hub

face with a depth micrometer. Mount a dial indica-

tor to read axial hub movement. Set the indicator

to “0”. Remove hub and install key(s). Remount

hub, drawing it up the shaft to the “0” set point.

Continue to advance hub up the taper to the de-

sired axial position. Use the indicator as a guide

only. A pre-set axial stop device can be helpful.

Check the nal results with a depth micrometer.

The hub may have to be heated in order to reach

the desired position on the shaft. DO NOT SPOT

HEAT THE HUB OR DISTORTION MAY OCCUR.

Install shaft locknut to hold hub in place.

D. Shaft Alignment.

Move equipment into place.

1. Soft Foot. The equipment must sit at on its

base (+/- 0.002 inches). Any soft foot must be

corrected now.

2. Axial Spacing. The axial spacing of the shafts

should be positioned so that the disc packs (ex-

ing elements) are flat when the equipment is

running under normal operating conditions. This

means there is a minimal amount of waviness in

the disc pack when viewed from the side. This

Coupling Installation