44

Operation

4. Manually open the oil isolating valve at the oil

separator outlet connection.

5. Open the isolating valve(s) before and after the

oil filter housings.

6. Manually open the stop valve on the oil bleed

return line from the element section and open

the expansion valve 1/2 of a turn.

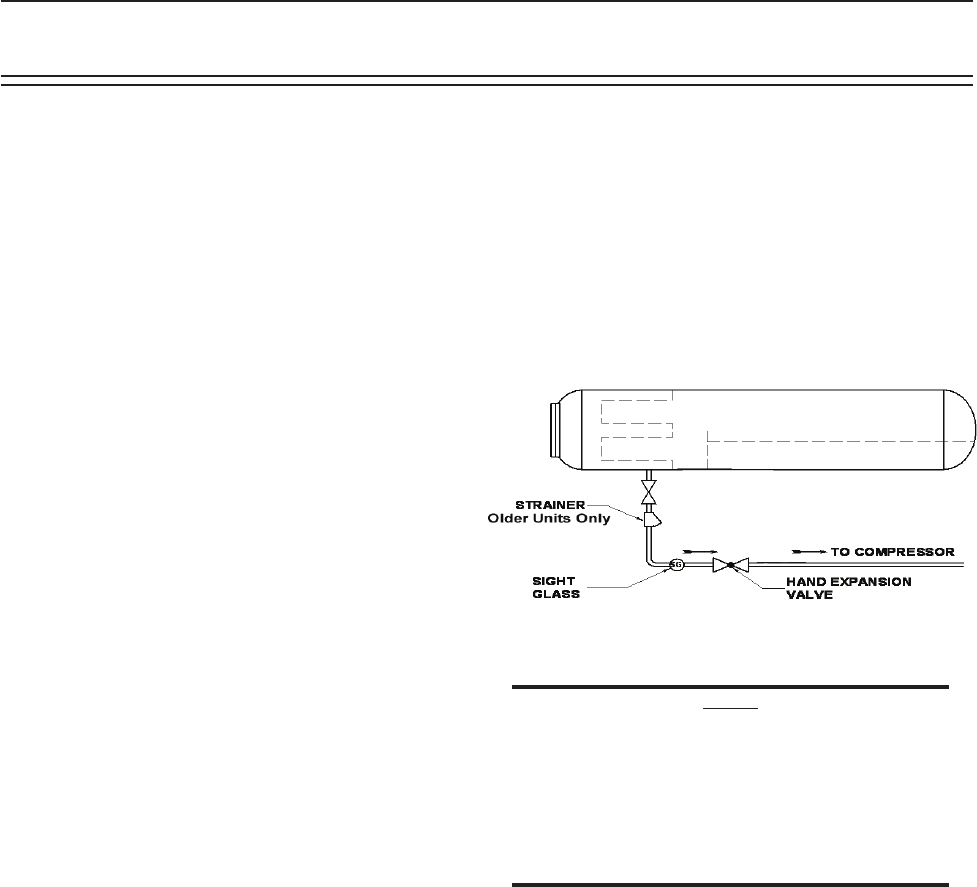

FIGURE 5.

OIL SEPARATOR BLEED LINE

NOTE:

The purpose of the oil bleed return assembly is to

collect any oil that passes through the oil separat-

ing element and returns that oil to the compres-

sor. The hand expansion valve should be adjusted

to prevent an oil level from forming in the sight

glass when the compressor is at 100% capacity.

Generally 1/2 to 1 turn open is satisfactory.

7. Open 1/4” high pressure gas line

valve piped to oil injection line just

enough to quiet compressor at 100%

capacity.

E. Compressor Pre Start-Up Check List

Before proceeding with actual starting of the

compressor, the items listed on the “Pre Start-Up

Check List” must be verified. Time and money will

be saved before the Vilter start-up technician ar-

rives. (See next page.)

3. Suction Pressure

Low suction pressure cutout stops the compres-

sor unit when the suction pressure drops below

the setpoint.

4. Oil Filter Differential

High oil filter differential cutout stops the com-

pressor unit when the difference between the

outlet and inlet of the filter exceeds the setpoint.

5. Oil Temperature

The oil temperature cutout stops the compres-

sor unit when the oil temperature is too high

or too low.

6. Discharge Temperature

The high discharge temperature cutout stops

the compressor unit when the discharge tem-

perature exceeds the setpoint.

INITIAL START-UP

A. Setting of Controls

(Refer to the appropriate microprocessor manual

for a list of initial settings.)

B. Valve Settings

1. The suction line uses separate stop and check

valves. Ensure the suction stop valve is open

prior to starting.

2. The ¼” suction equalization valve should be

closed during operation. The valve enables the

unit to slowly equalize to low side pressure dur-

ing off periods. This valve must be adjusted to

minimize oil loss when compressor stops.

3. The discharge line uses separate stop and check

valves. Ensure the discharge valve is open prior

to starting.