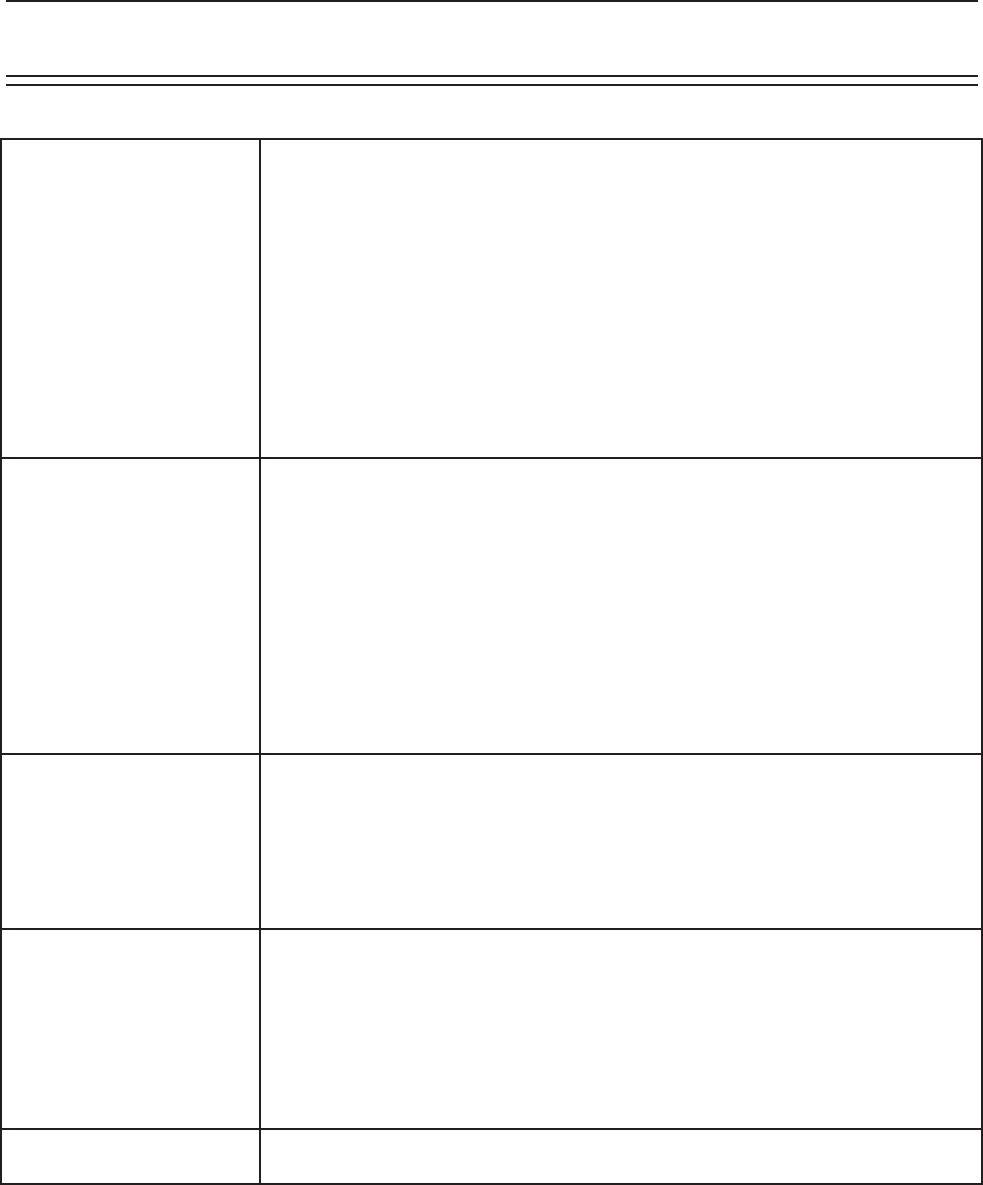

35

Note 1: TP1 and TP2 are plated-thru holes located close to the slotted optocouplers on the board. They are clearly

marked on the board silkscreen legend.

Note 2: The TS1 wire pads are where the motor thermal switch leads solder into the circuit board. They are clearly

marked on the board silkscreen legend and are oriented at a 45 degree angle.

*__________________ This indicates a skipped state in the patterns generated by the optocouplers as the

motor moves. This error means that the slide valve actuator is no longer transmit-

ting accurate position information. The actuator should be recalibrated as soon as

possible. This code will not clear until the actuator is recalibrated.

This code can be caused by:

1. The motor speed exceeding the position sensors ability to measure it at some

time during operation. A non-functioning motor brake is usually to blame.

2. The actuator is being operated where strong infrared light can falsely trigger

the slotted optocouplers, such as direct sunlight. Shade the actuator when the

cover is off for service and calibration. Do not operate the actuator with the

cover off.

*__*__*____________ The motor has overheated. The actuator motor will not run until it cools. Once the

motor cools, the actuator will resume normal operation.

Motor overheating is sometimes a problem in hot and humid environments when

process conditions demand that the slide valve reposition often. Solutions are

available; consult your Vilter authorized distributor for details.

Another possible cause for this error is a stuck motor thermal switch. The ther-

mal switch can be tested by measuring the DC voltage with a digital multi-meter

between the two TS1 wire pads (see Note 2). If the switch is closed (normal opera-

tion) you will measure 0 Volts.

******************** The 24V supply is voltage is low. This will occur momentarily when the actuator is

powered up and on power down.

If the problem persists, measure the voltage using a digital multi-meter between

terminals 3 and 4 of the small terminal block. If the voltage is >= 24V, replace the

actuator.

_******************* The EEPROM data is bad. This is usually caused by loss of 24V power before the

calibration procedure was completed. The actuator will not move while this error

code is displayed. To clear the error, calibrate the actuator. If this error has oc-

curred and the cause was not the loss of 24V power during calibration, possible

causes are:

1. The EEPROM memory in the micro-controller is bad.

2. The large blue capacitor is bad or has a cracked lead.

*****____*__________ Micro-controller program failure. Replace the actuator.

Slide Valve Actuator Trouble Shooting Guide