65

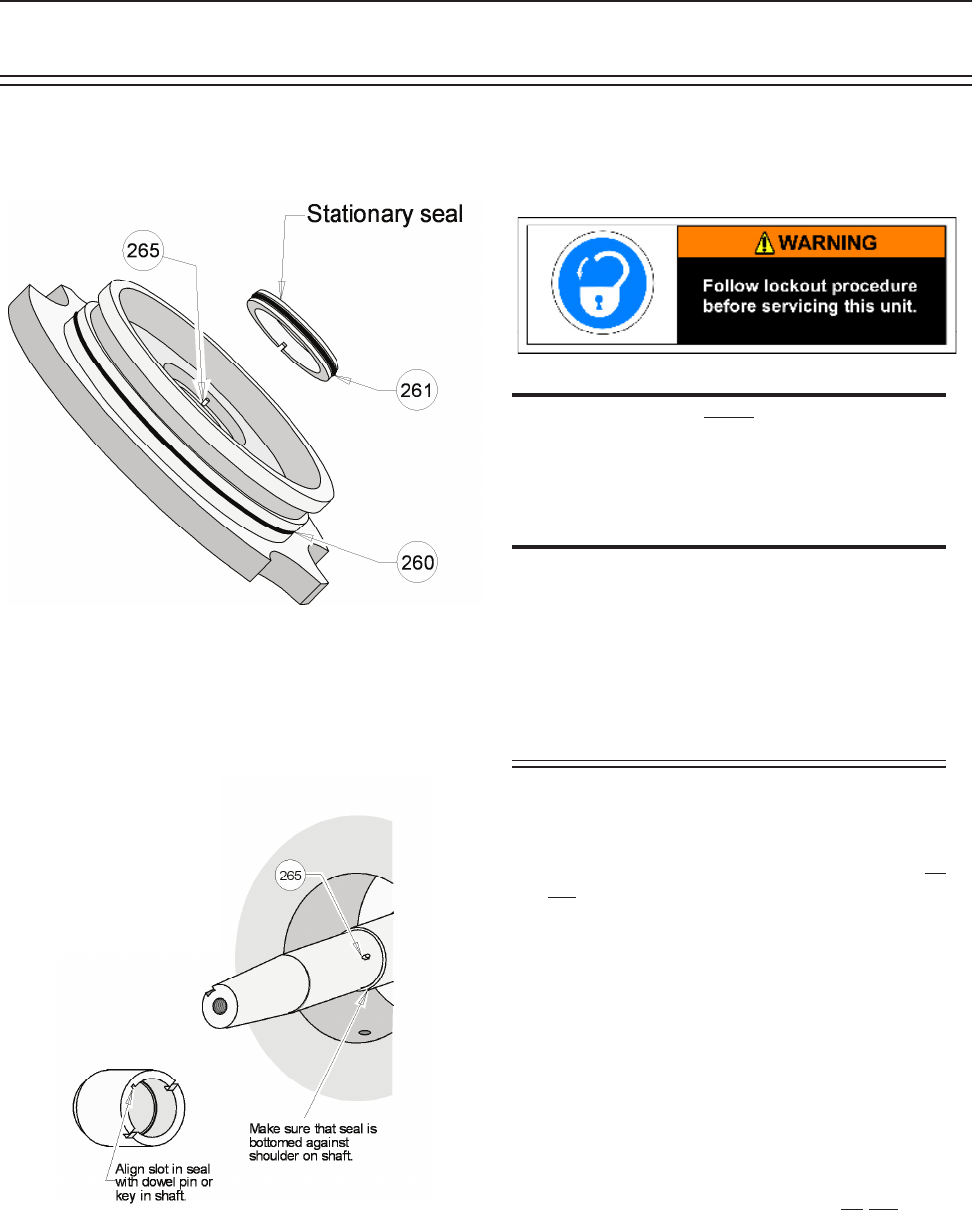

COMPRESSOR SEAL INSTALLATION

NOTE:

When replacing the stationary members of the seal

on the VSS 451 thru VSS 601 the roll pin in the cover

is used only with the seal assembly having a station-

ary mirror face. If a seal assembly with a stationary

carbon face is installed, the roll pin must be removed.

A) Install new oil seal in cover.

CAUTION

Care must be taken when handling the shaft seal and

mirror face so it is not damaged. Do not touch the

carbon or mirror face as body oil and sweat will cause

the mirror face to corrode.

B) To install the carbon cartridge part of the seal

in the seal cover; clean the seal cover, remove

protective plastic from the carbon cartridge, do

not wipe or touch the carbon face. Lubricate the

sealing O-ring with clean compressor lubricating

oil. If applicable, align the hole on the back of

the carbon cartridge with the dowel pin in the

seal cover. Install cartridge using seal installation

tool or similar (see tool lists).

C) Wipe clean, the compressor input shaft and the

shaft seal cavity in the compressor housing. Ap-

ply clean compressor oil to the shaft seal seating

area on input shaft.

D) Lubricate the inside area of the rotating seal with

clean compressor lubricating oil, do not wipe

or touch the face of the rotating portion of the

seal. Align the slot in the rotating seal with the

drive pin on the compressor input shaft. Care-

fully push the seal on, holding onto the outside

area of the seal until the seal seats against the

Service