70

C) The command shaft bearing (435) is a press

t on the command shaft (413). Remove the

command shaft bearing with a suitable press.

D) Remove the O-ring seal (445) from the com-

mand shaft housing. The command shaft bush-

ing (433 and 436) might have to be removed to

gain access to o-rings. Replace bushing if the

bore is deeply scored or excessively worn.

COMMAND SHAFT BEARING AND O-RING

SEAL REASSEMBLY

A) Install new O-ring seal in housing and lubricate

the O-ring with clean compressor oil. A vent

hole is provided in the command shaft bearing

housing to allow any refrigerant and oil that may

leak past the O-ring seal to vent to atmosphere

and not into the slide valve motor housing.

Install snap ring retainer and washer on the

command shaft.

B) Remove any burrs from the command shaft to

prevent damage to the O-ring when assembling.

Press the command shaft bearing onto the

command shaft. Insert the command shaft into

the housing applying pressure on outer race of

bearing. Make sure the bearing is fully seated

in the command shaft housing. Install the snap

ring retainer in the command shaft housing.

C) Install command shaft assembly.

Reference “Parts

Section” for current

Housing

436

445

Ven t hole.

Service

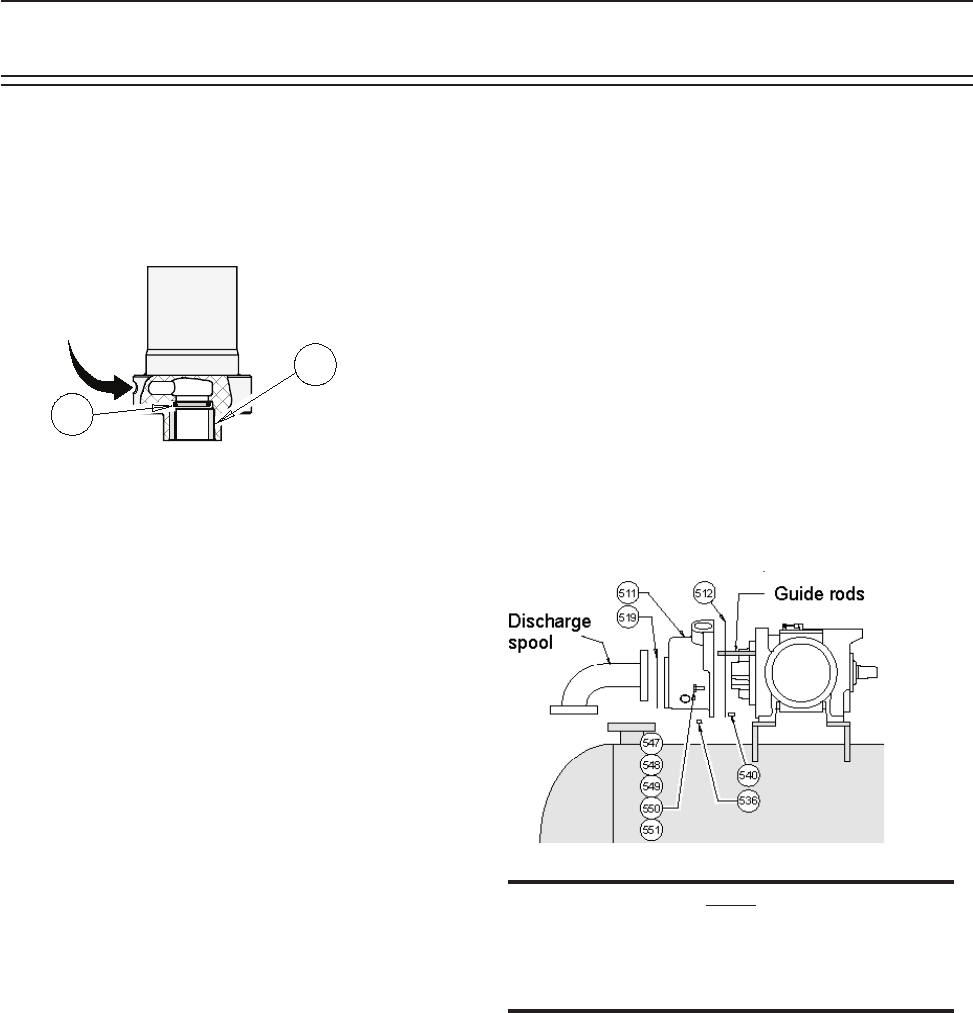

DISCHARGE MANIFOLD REMOVAL

A) Remove both control actuators and command

shaft assemblies.

B) On VSS 451-3001 compressors, remove the dis-

charge spool between the manifold and separator.

Remove one bolt from each side of the discharge

manifold and install (2) guide rods approximately

6” long, to support the manifold. Remove the

remaining bolts (note length and location of bolts)

and take off the discharge manifold.

Note: Mainfold has dowel pins to locate it on the

compressor housing. Therefore, remove manifold

straight back approximately 1” as not to break

dowel pins.

NOTE:

When removing the discharge manifold on VSG 301-701

compressor the compressor must be properly supported

to keep the compressor from moving when the manifold

is removed.

C) On VSM 301-701 compressors unbolt the dis-

charge ange from the discharge manifold.

D) Remove one bolt from each side of the discharge

manifold and install (2) guide rods approximately

6” long, to support the manifold. Remove the

remaining bolts (note length and location of bolts)

and take off the discharge manifold.