26

will result in a exing element that is centered and

parallel to its mating ange faces. Move the con-

nected equipment to accomplish the above.

NOTE: The disc pack is designed to an optimal thick-

ness and is not to be used for axial adjustments.

See documentation that came with the coupling for

complete specications.

3. Angular Alignment. Rigidly mount a dial indicator

on one hub or shaft, reading the face of the other

hub ange, as shown on next page. Rotate both

shafts together, making sure the shaft axial spacing

remains constant. Adjust the equipment by shim-

ming and/or moving so that the indicator reading

is within .002 inch per inch of coupling ange.

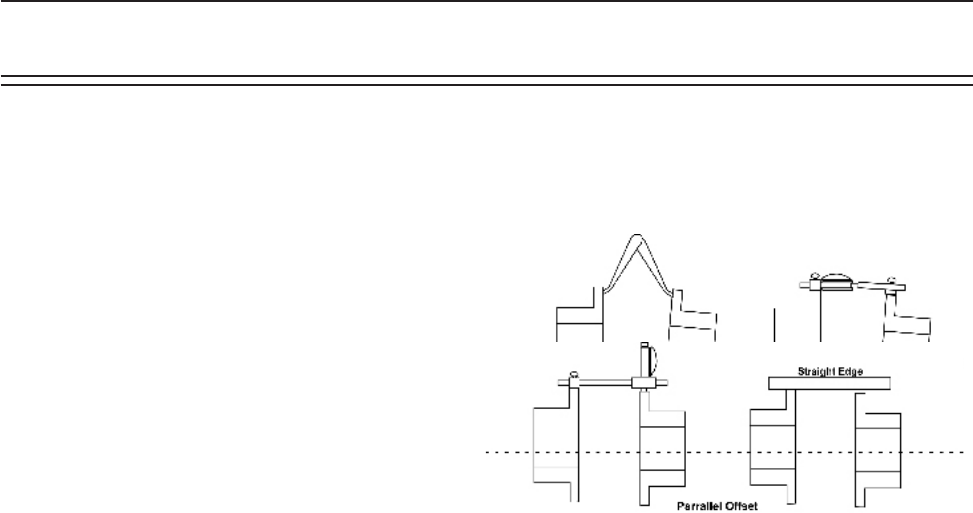

4. Parallel Offset. Rigidly mount a dial indicator on

one hub or shaft, reading the other hub ange out-

side diameter, as shown in Figure 3. Indicator set-up

sag must be compensated for. Rotate both shafts

together. Adjust the equipment by shimming and/

or moving so that the indicator reading is within

.002 inch per inch of the axial length between ex

elements. See drawing below.

Note: If the driver or driven equipment alignment

specication is tighter than these recommendations,

the specication should be used. Also, be sure to

compensate for thermal movement in the equipment.

The coupling is capable of approximately four time

the above shaft alignment tolerances. However, close

alignment at installation will provide longer service

with smoother operation.

E. Final assembly

With the coupling in good alignment the bolts will t

through the holes in the anges and the disc packs

more easily.

1. If the coupling arrived assembled, the disc packs

are still attached to the center ring. Before tak-

ing the discs packs off, rst install one hub bolt

through each disc pack and secure with lock out.

This will help when the pack is reinstalled late. If

the coupling was shipped disassembled, the bolt

through the pack is not required as the discs in the

pack are factory taped together.

2. Remove the long bolts. Mount the disc packs

on the hubs with one bolt through the disc pack

aligned with a clearance hole in the hub. Install

the short bolts through the hub, disc pack, bevel

washer or link, and secure with a lockout.

NOTE: All bolt threads should be lubricated. A clean

motor oil is recommended. On size 226 and larger, a

link must be put on bolt rst. Remove the disc pack

alignment bolt. Proceed to mount the second disc

pack to the other hub in the same way.

3. Position one set of short bolts in each hub on

top. Now slide the center ring down into place

straddling the short bolts with the center ring

bushings. If coupling is dynamically balanced, the

center ring match marks must lineup with both

hub match marks. When one bushing is in-line

with the hole in the disc pack, slide one long bolt

through washer or link, disc pack, center ring,

disc pack, washer or link, and then secure with a

locknut. On size 226 and larger a link must be put

on the bolt rst. Now install the rest of the long

bolts in the same manner.

4. Torque the long bolt locknuts at this time.

Note: Alignment of C-Flange Units should be

checked when compressor or motor are replaced.

Installation