42

A. Screw Compressor Control And Operation

1. Starting, Stopping and Restarting the Com-

pressor.

Before the screw compressor unit is started,

certain conditions must be met. All of the

safety setpoints must be in a normal condition,

and the suction pressure must be above the

low suction pressure setpoint to assure that a

load is present. When the “On-Off” switch or

“Manual-Auto” button is pressed, the oil pump

will start. When sufficient oil pressure is built

up and the compressor capacity control and

volume ratio slide valves are at or below 10%,

the compressor unit will start.

If the compressor is in the automatic mode, it

will now load and unload and vary the volume

ratio in response to the system demands.

Stopping the compressor unit can be accom-

plished a number of ways. Any of the safety

setpoints will stop the compressor unit if an

abnormal operating condition exists. The com-

pressor unit “On-Off” or stop button will turn

the compressor unit off as will the low pressure

setpoint. If any of these conditions turns the

compressor unit off, the slide valve motors will

immediately energize to drive the slide valves

back to 5% limit. The control motors will be

de-energized when the respective slide valve

moves back below 5%. If there is a power failure,

the compressor unit will stop. If the manual

start on power failure option is selected (see ap-

propriate Microprocessor Instruction Manual),

restarting from this condition is accomplished

by pushing the reset button to insure positive

operator control. If the auto start on power fail-

ure option is selected (see appropriate Micro-

processor Instruction Manual), the compressor

unit will start up after a waiting period. With

both options, the compressor slide valves must

return below their respective 5% limits before

the compressor unit can be restarted.

2. Slide Valve Control Actuators

Capacity and volume ratio control of the screw

compressor is achieved by movement of the

respective slide valves, actuated by electric

motors.

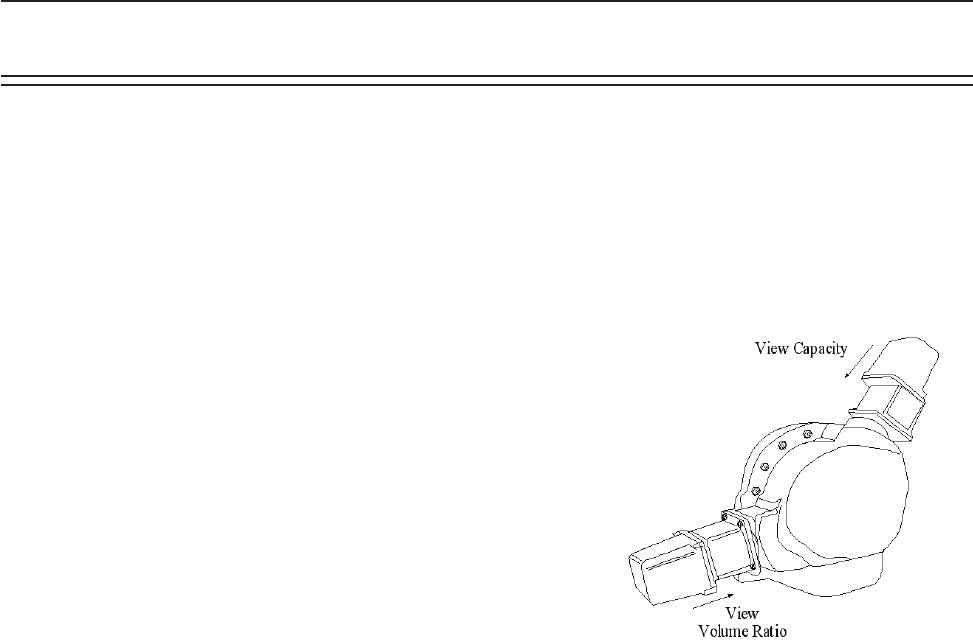

FIGURE 4.

SLIDE VALVE MOTOR LOCATION

When viewing the compressor from the dis-

charge end (opposite the drive end), the upper

motor is for capacity control. The command

shaft turns (see Table 1) to decrease the capac-

ity to 10% and reverses to increase the capacity

to 100%. The lower motor is for volume ratio

control. The command shaft turns to reduce the

volume ratio to 2.0, and reverses to increase the

volume ratio to 5.0.

Actuation of the electric motors can be done

manually or automatically. To actuate the mo-

tors manually, place the desired mode selector

in the manual position and push the manual

Increase or Decrease buttons. In the automatic

mode, the microprocessor determines the direc-

tion to actuate the electric motors. However,

in the automatic mode, there is an “On” and

“Off” time for the capacity control motor. The

“On” time is the time in which the slide valve

moves, and the “Off” time is the time in which

the system is allowed to stabilize before another

change in slide valve position.

Operation

Note:

Optical Actuators CAN NOT

be manually rotated.

(The VSM 501-701 models

will have motor locations

oppositeofgure#6)