58

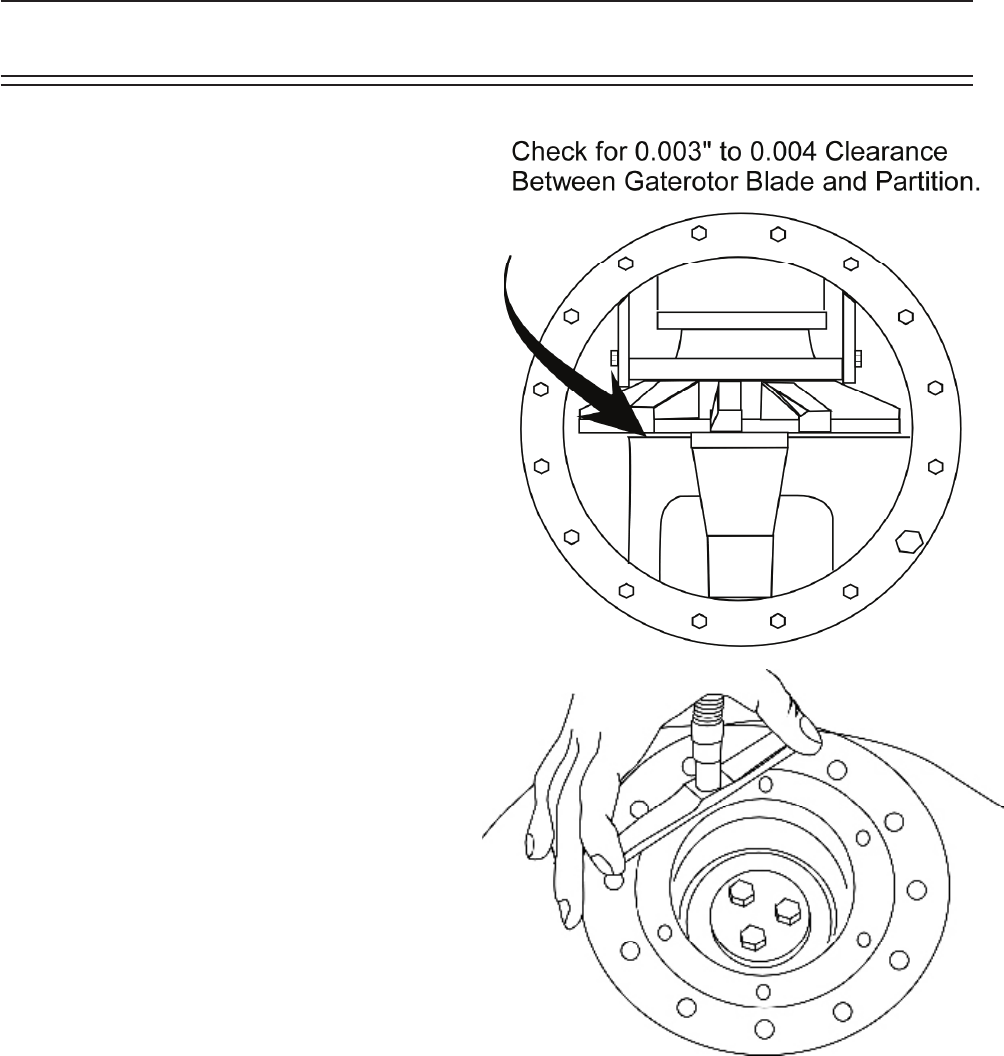

D) Set the clearance between the gate rotor blade

and the shelf.

1. Place a piece of 0.003”-0.004” shim stock

between the gate rotor blade and the shelf.

2. Measure the depth from the top of the com-

pressor case to the top of the thrust bearing

housing. This determines the amount of

shims needed for the correct clearance.

3. Use factory installed shim pack (106) and

bearing housing cover (116) without the O-

ring (143). Check the clearance between the

entire gate rotor blade and the shelf, rotate

the gate rotor to nd the tightest spot. It

should be between 0.003”-0.004”. Make

adjustments, if necessary. It is preferable to

shim the gate rotor blade looser rather than

tighter against the shelf.

Note: Replacement blades are precisely the same

dimensionally as blades installed originally at fac-

tory: Therefore, the same amount of shims will be

required for replacement blades.

E) After clearance has been set install a new O-ring

(143) on bearing housing cover, install cover and

tighten the bolts to the recommended torque

value.

F) Install side cover with a new gasket. Tighten the

bolts to the recommended torque value. The

unit can then be evacuated and leak checked as

outlined in section 0.03.

Service