MAINTENANCE

D-2 D-2

POWER WAVE 355/405

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Have qualified personnel do the maintenance

work. Always use the greatest care when

working near moving parts.

Do not put your hands near the cooling blower

fan. If a problem cannot be corrected by

following the instructions, take the machine to

the nearest Lincoln Field Service Shop.

-----------------------------------------------------------------------

WARNING

VISUAL INSPECTION

Clean interior of machine with a low pressure air

stream. Make a thorough inspection of all compo-

nents. Look for signs of overheating, broken leads or

other obvious problems. Many problems can be

uncovered with a good visual inspection.

ROUTINE MAINTENANCE

1. Every 6 months or so the machine should be

cleaned with a low pressure airstream. Keeping

the machine clean will result in cooler operation

and higher reliability. Be sure to clean these

areas:

• All printed circuit boards

• Power switch

• Main transformer

• Input rectifier

• Auxiliary Transformer

• Reconnect Switch Area

• Fan (Blow air through the rear louvers)

2. Examine the sheet metal case for dents or breakage.

Repair the case as required. Keep the case in good

condition to insure that high voltage parts are protected

and correct spacings are maintained. All external sheet

metal screws must be in place to insure case strength

and electrical ground continuity.

PERIODIC MAINTENANCE

Calibration of the POWER WAVE 355/405 is critical to

its operation. Generally speaking the calibration will

not need adjustment. However, neglected or improper-

ly calibrated machines may not yield satisfactory weld

performance. To ensure optimal performance, the cali-

bration of output Voltage and Current should be

checked yearly.

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground

• Always wear dry insulating gloves.

------------------------------------------------------------------------

EXPLODING PARTS can cause

injury.

•

Failed parts can explode or cause other

parts to explode when power is applied.

•

Always wear a face shield and long

sleeves when servicing.

------------------------------------------------------------------------

See additional warning information

throughout this Manual.

------------------------------------------------------------------------

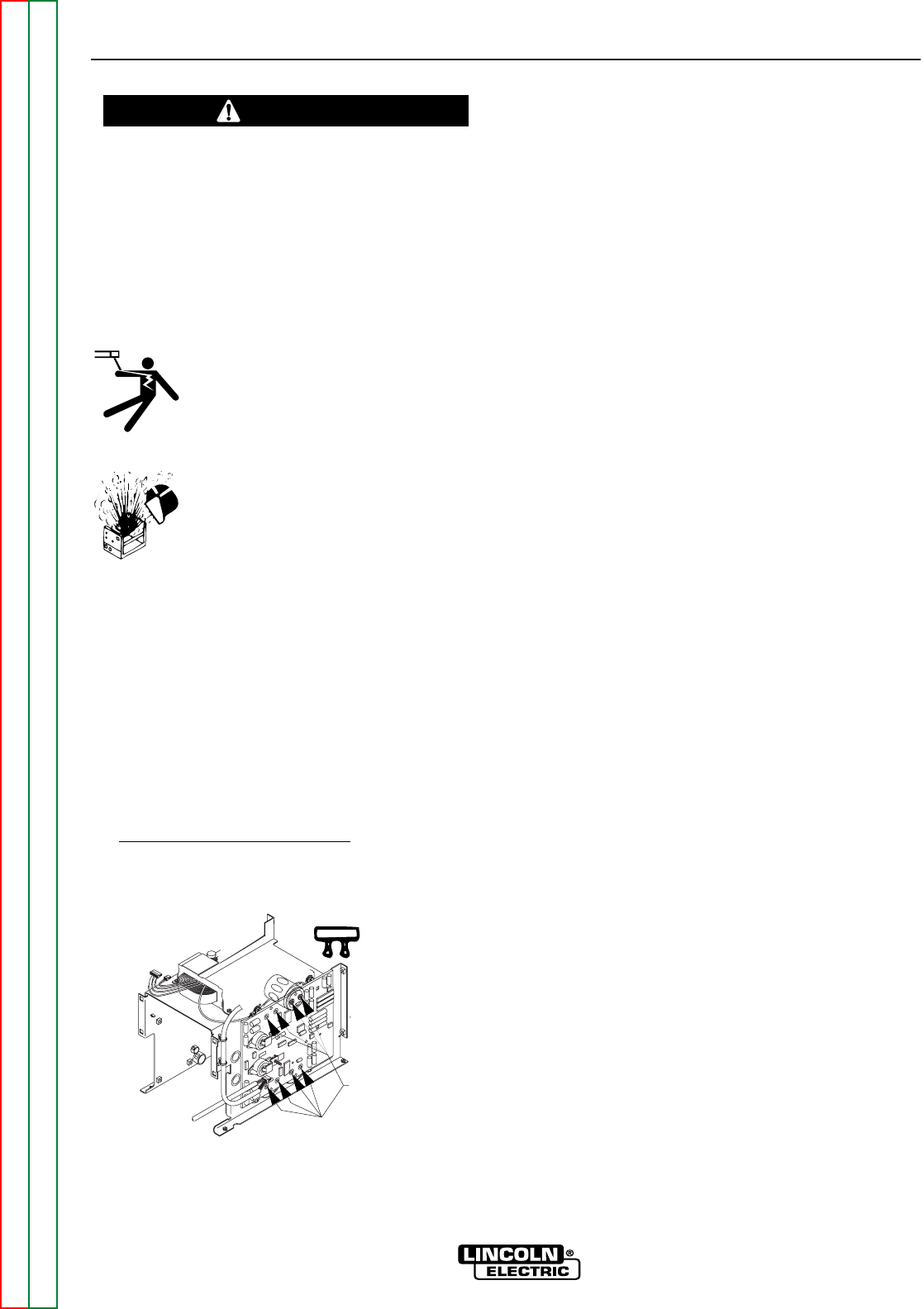

CAPACITOR DISCHARGE PROCEDURE

1. Obtain a power resistor (25 ohms, 25 watts).

2. Hold resistor body with electrically insulated glove.

DO

NOT TOUCH TERMINALS. Connect the resis-

tor terminals across the two studs in the position

shown. Hold in each position for 1 second.

Repeat for all four capacitors.

3. Use a DC voltmeter to check that voltage is not

present across the terminals on all four capaci-

tors.

CAPACITOR

TERMINALS

RESISTOR