Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

LN-7 GMA WIRE FEEDER

OPERATIONB-14

MAKING A WELD

1. Inch the electrode through the gun and cable. For

solid wire, cut the electrode within approximately

3/8 in. of the end of the contact tip. If using cored

wire, cut the electrode within 3/4 in. of the

extension guide.

2. Connect the work cable to the metal to be welded.

The work cable must make good electrical contact

with the work. The work must also be grounded.

When using an open arc process, it is necessary to

use correct eye, head, and body protection.

3. Position the electrode over the joint. The end of

the electrode may be lightly touching the work.

4. Lower your welding helmet. Close the gun trigger

and begin welding. Hold the gun so the contact tip

to work distance gives the correct electrical

stickout as required for the procedure being used.

5. To stop welding, release the gun trigger and then pull

the gun away from the work after the arc goes out.

WIRE REEL CHANGING

At the end of a coil, remove the last of the old electrode

from the conductor cable. Either pull it out at the

nozzle, or use the following procedure.

1. Cut off the end of the electrode at the gun end. Do

not break it off by hand. Breaking by hand puts a

slight bend in the wire, making it difficult to pull it

back through the nozzle.

2. Uncouple the gun conductor cable from the

conductor block on the wire feeder drive unit and

lay the gun cable out straight.

3. Using pliers, grip the wire and pull it out of the

cable from the connector end.

4. After the electrode has been removed, connect

the gun conductor back to the wire feeder.

5. Load a new reel of electrode per the instructions

for the specific reel type given previously in this

section.

OPTIONAL K416 ANALOG AND

K417 DIGITAL VOLTMETER KITS

Lincoln Specified Procedures give voltmeter readings

taken between the work and the gun cable brass

connection block inside the LN-7 GMA. To match these

voltage readings, the #21 lead should be extended

directly to the work per the instructions on the wire

feeder to power source connection diagrams given in

the Installation Section.

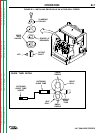

To read volts, set the “Electrode Polarity” switch, Figure

B.9, to the same polarity as the electrode lead

connection to the power source.

The K417 Digital Voltmeter Kit has a hold feature that

will freeze the last arc voltage reading at the moment

the trigger is released to stop welding. This feature

allows the welding operator to easily check the arc

voltage and make adjustments if necessary to match

procedures. For accuracy, it is important to release

the gun trigger and the lift the gun away from the

work.

The hold circuit automatically releases about six

seconds after the gun trigger is released. It is also

released when the trigger is closed again to begin

welding.

FIGURE B.9 – ELECTRODE POLARITY SWITCH.

ELECTRODE

POLARITY

SWITCH

WARNING