Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

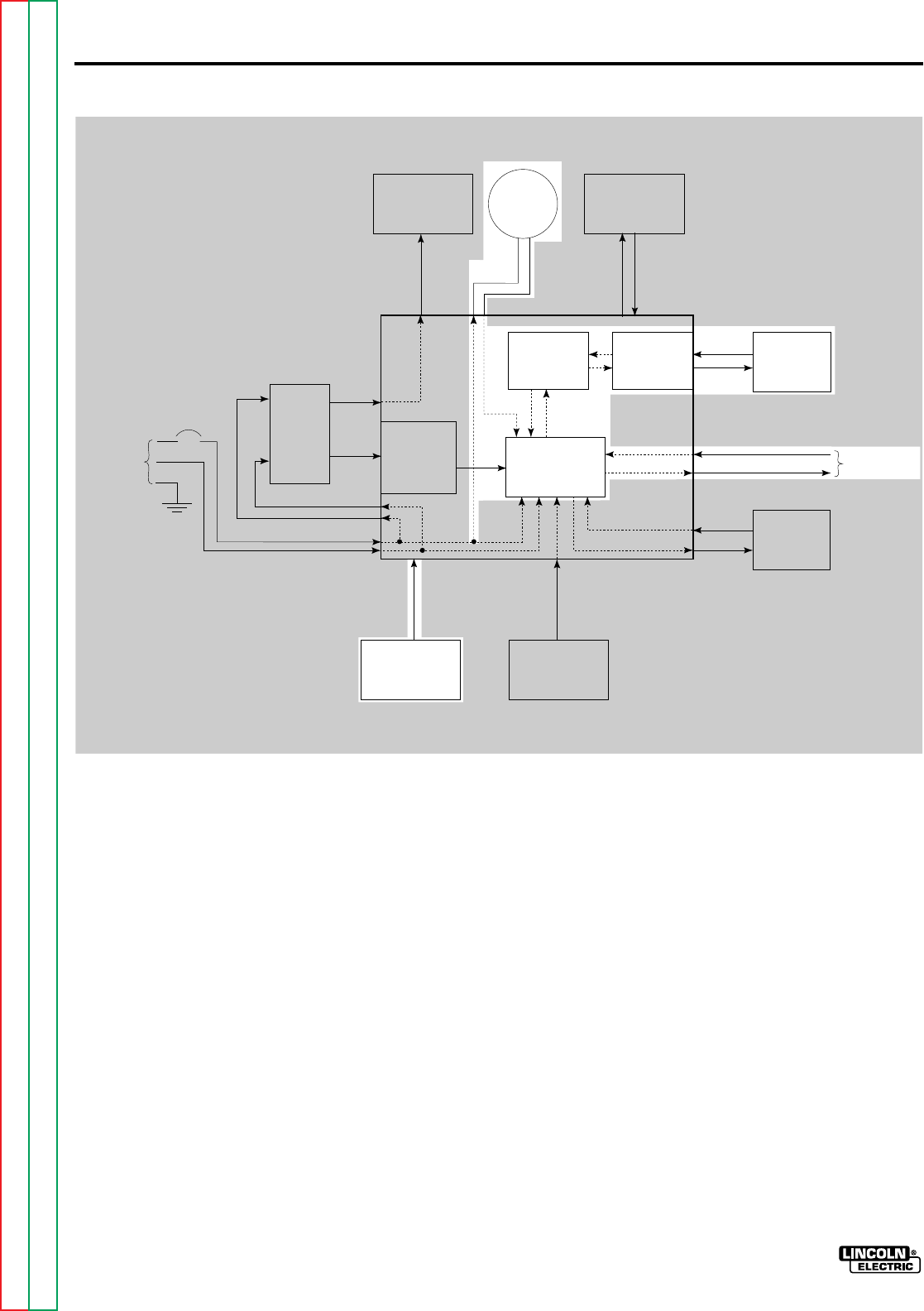

E-4 THEORY OF OPERATION

CONTROL RELAY CIRCUIT

The first contact closes to allow 115 VAC to

energize the gas solenoid. This allows

shielding gas to flow to the gun. The second

contact of the control relay closes the circuit

in the welding power source contactor circuit.

This signals the welding power source to

provide power to the gun. The last set of

contacts on the control relay disables the

motor dynamic braking circuit and closes the

motor power supply circuit. See Figure E.3.

When the control relay closes the motor

contacts, the SCR power circuit supplies a

DC voltage to the wire drive motor. This

voltage is dependent on the setting of the

wire speed control. The faster the speed

setting, the higher the voltage that is applied

to the wire drive motor. The gearbox

transfers the power of the rotating motor to

the drive roll. On a four-roll wire feeder, the

gearbox also splits the drive power to two

separate drive rolls.

When the trigger is released, the control

relay is de-energized. This opens the

contacts which de-energize the gas

solenoid, open the welding power source

contactor circuit, and stop the wire drive

motor. The dynamic braking circuit engages

to rapidly stop the wire drive motor and

prevent wire overrun.

LN-7 GMA WIRE FEEDER

FIGURE E.3 – CONTROL CIRCUITS.

TRIGGER

TRANS-

FORMER

24 VAC

8.8 VAC

115 VAC

CIRCUIT

BREAKER

OPTIONAL

METER KIT

OPTIONAL

TIMER OR

BURNBACK KIT

WIRE

SPEED

CONTROL

CONTROL

BOARD

WIRE DRIVE

MOTOR

5-95 VDC

GUN

TRIGGER

SCR

POWER

CIRCUIT

FROM

WELDING

POWER

SUPPLY

DIODE

RECTIFIER

NETWORK

115 VAC

GAS

SOLENOID

TO WELDING

CONTACTOR

CURRENT

LIMITING

CIRCUIT

115 VAC

GROUND

LEAD

PROTECTOR

CR1

CONTROL

RELAY

24 VDC

NOTE: Unshaded areas of block logic diagrams are the subject of discussion.