OM-196 188 Page 110

1 Mig Type Display

With DVC Voltage Correction On,

the unit uses closed-loop feedback

or voltage sensing leads to

maintain set voltage parameters.

With DVC Voltage Correction Off,

feedback from the arc is not used

for closed-loop feedback to

maintain voltage parameters.

Feedback from the arc is still used

for other functions.

Be sure voltage sensing leads are

connected.

1

MIG

Voltage

Correction

> DVC Off

Access

> Mig Type

Aux Out

Voltage

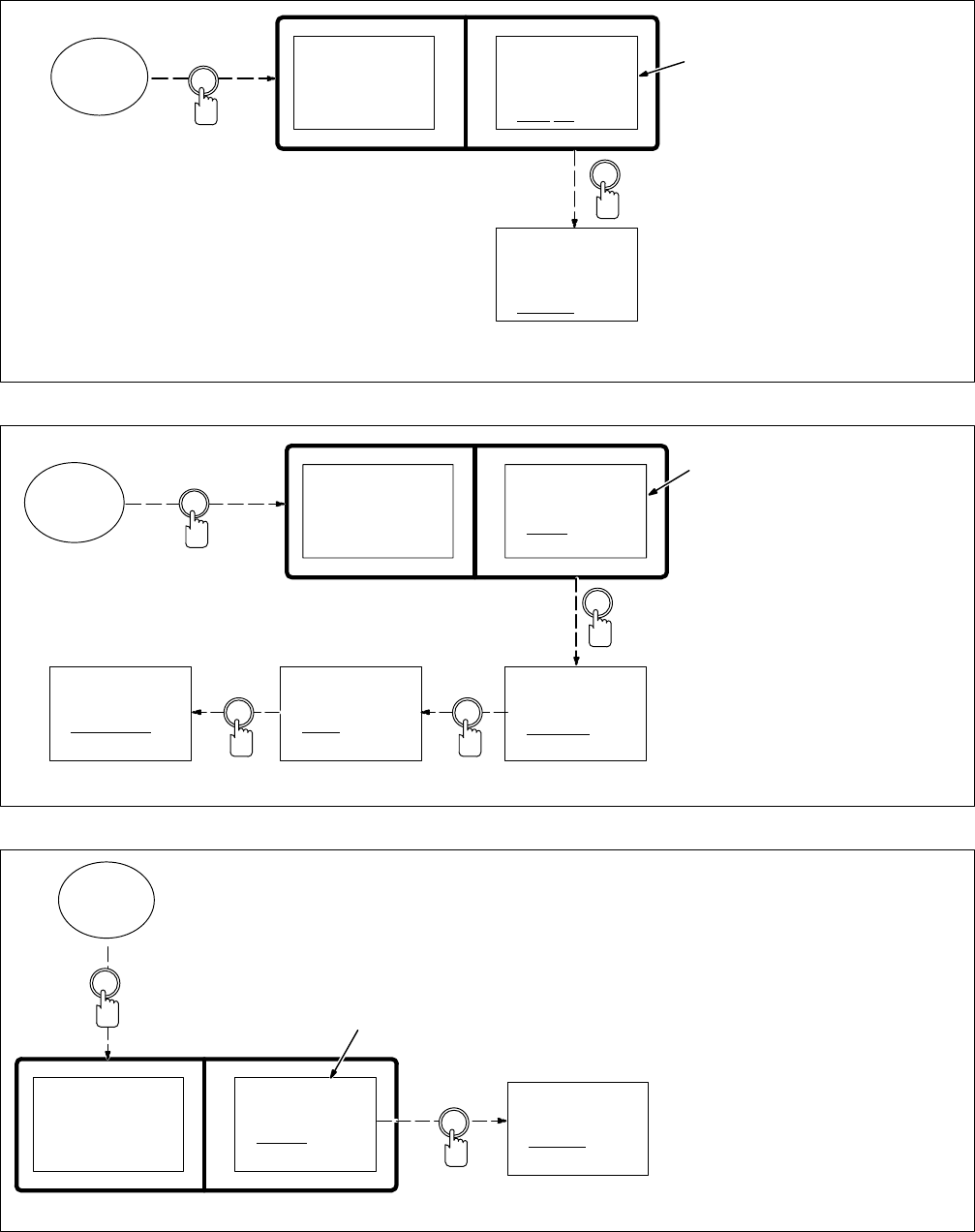

14-4. Selecting Voltage Correction

Press Mode

Select

Increase

Access

Setup

Display

MIG

Voltage

Correction

> DVC On

1 Auxiliary Output

This output can be set to several

conditions:

On whenever the wire feeder is op-

erating

On during the welding arc until arc

goes out

On during the entire weld cycle

Off or never On.

1

Access

Mig Type

> Aux Out

Voltage

Aux

Turn On

> w/Feeder

14-5. Selecting Auxiliary Output

Access

Setup

Display

Press Mode

Select

Increase

Increase

Aux

Turn On

> w/Arc

Aux

Turn On

> w/Weld Cyc

Increase

Aux

Turn On

> Never

1 Voltage Feedback Display

The Internal setting allows the unit

to obtain voltage feedback directly

from the welding power source out-

put terminals.

When using the V. Sense setting,

arc voltage feedback is through the

voltage sense leads connected to

the feeder. Use this setting when

there is more than 50 ft (15 m) of

weld cable used or when using

Touch Sensor.

Mig Type

Aux Out

> Voltage

ArcStart

Control

Feedback

> Internal

1

Control

Feedback

> V Sense

14-6. Selecting Voltage Sensing Method

Access

Setup

Display

Increase

Press Mode

Select