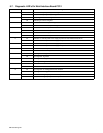

OM-196 188 Page 28

1 Memory CRC Error Display

Corrupted program data has been detected

or loaded. The “X” value indicates the pro-

gram number.

May be caused by incompatible information

on the data card or bad memory.

2 Memory Range Error Display

Improper welding power source range is

selected. The “X” value indicates the pro-

gram number.

May be caused by improper range settings

or improper data loaded into the interface

unit.

3 No Volt Sensed Error Display

The arc voltage sense circuit did not receive

feedback within the required time after an arc

was established.

May be caused by an inability to establish an

arc in the pulse schedule, or a lack of voltage

feedback.

4 No Tach Sensed Error Display

The motor tachometer feedback is not

reaching the control.

May be caused by obstructions in the wire

feed system or a faulty wire drive system.

5 Arc Stop Error Display

Trouble is occurring at arc end.

May be caused by obstructions in the wire

feed system or a faulty wire drive system or

torch is touching part at end of weld.

6 Arc Start Error Display

Trouble is occurring at arc start.

May be caused by obstructions in the wire

feed system or a faulty wire drive system.

7 Stop Weld Cycle Error Display

An error has been detected and the robot

hasn’t stopped the weld cycle, causing the

interface unit to stop the weld cycle and wait

for the robot to stop.

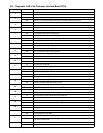

8 Error Card Read Display

The card reader is not working properly.

May be caused by a bad data card, a bad

data card reader, a faulty microprocessor

circuit board, or a wiring problem.

9 No Flow Detected

No coolant is detected after preflow in the

weld cycle. Check coolant system and flow

switch for proper operation.

10 Ground Current Detect Error Display

Weld current has been detected in the earth

ground connection.

May be caused by a conductor making

connection to the unit chassis.

11 Wire Stick Error Display

The welding wire has stuck to the workpiece

at the end of the weld.

May be caused by poor weld conditions.

12 Arc Fail Time Out Error Display

An arc was not established within the allotted

time.

May be caused by an inoperable wire drive,

absence of shield gas, or improperly operat-

ing welding power source.

13 No Input IPM Display

Analog IPM (inches per minute) from robot is

not being received.

May be caused by having no wire feed speed

programmed at the robot.

1

5-5. Front Panel Error Displays

Mem CRC E r r o r

Stop Weld Cycle Err

2

Mem Range Er r

3

No Vo l t Sensed Er r or

4

No Tach Sensed Er r or

5

Arc Stop Er ror

6

Arc Star t Er ror

7

8

Er ror Card Read

9

No F l ow De t ec t ed

10

Grd Cur rent Det ec t

11

Wi re St i ck Er ror

12

Arc Fai l TimeOut Err

13

No I nput IPM