Vertical Drilling Motor, Type GE752, GEK–91584D

17

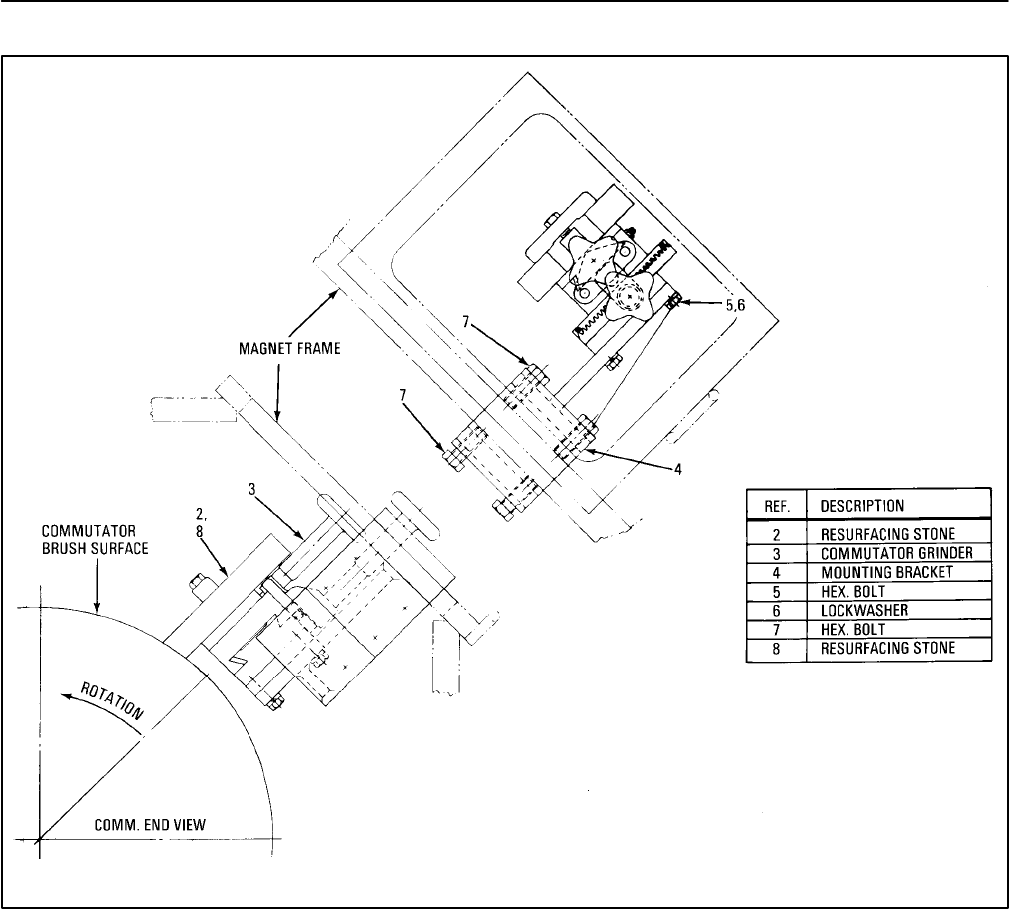

FIG. 11. COMMUTATOR GRINDER. E–18249.

NOTE: For most applications, finish–grade

resurfacing stones are recommended. Medium

grade stones can be used for rough grinding a

deeply grooved or threaded commutator, or a

commutator with deep flat spots, followed by fi-

nish–grade stones for the final grinding. If new

stones will be used, they should be contoured

on a Carborundum wheel to approximate the

curvature of the commutator.

Install the stones in the grinder so the entire surface

of the commutator will be resurfaced when the carriage

is traversed from side–to–side. Proceed with alignment

of the grinder as follows:

Install the resurfacing stones in the grinder and pro-

ceed as follows:

1. Traverse the carriage to one end of the commu-

tator and check the clearance between the com-

mutator surface and one stone with a feeler

gauge or a fiber strip (approximately 0.030 in.

thick). Traverse the carriage to the other end of

the commutator and check the clearance under

the same stone. The clearance should be the

same at both ends. If clearance is not equal at

both ends, adjust the mounting bracket by

means of the set screws to obtain equal clear-

ance at both ends.