GEK–91584D, Vertical Drilling Motor, Type GE752

64

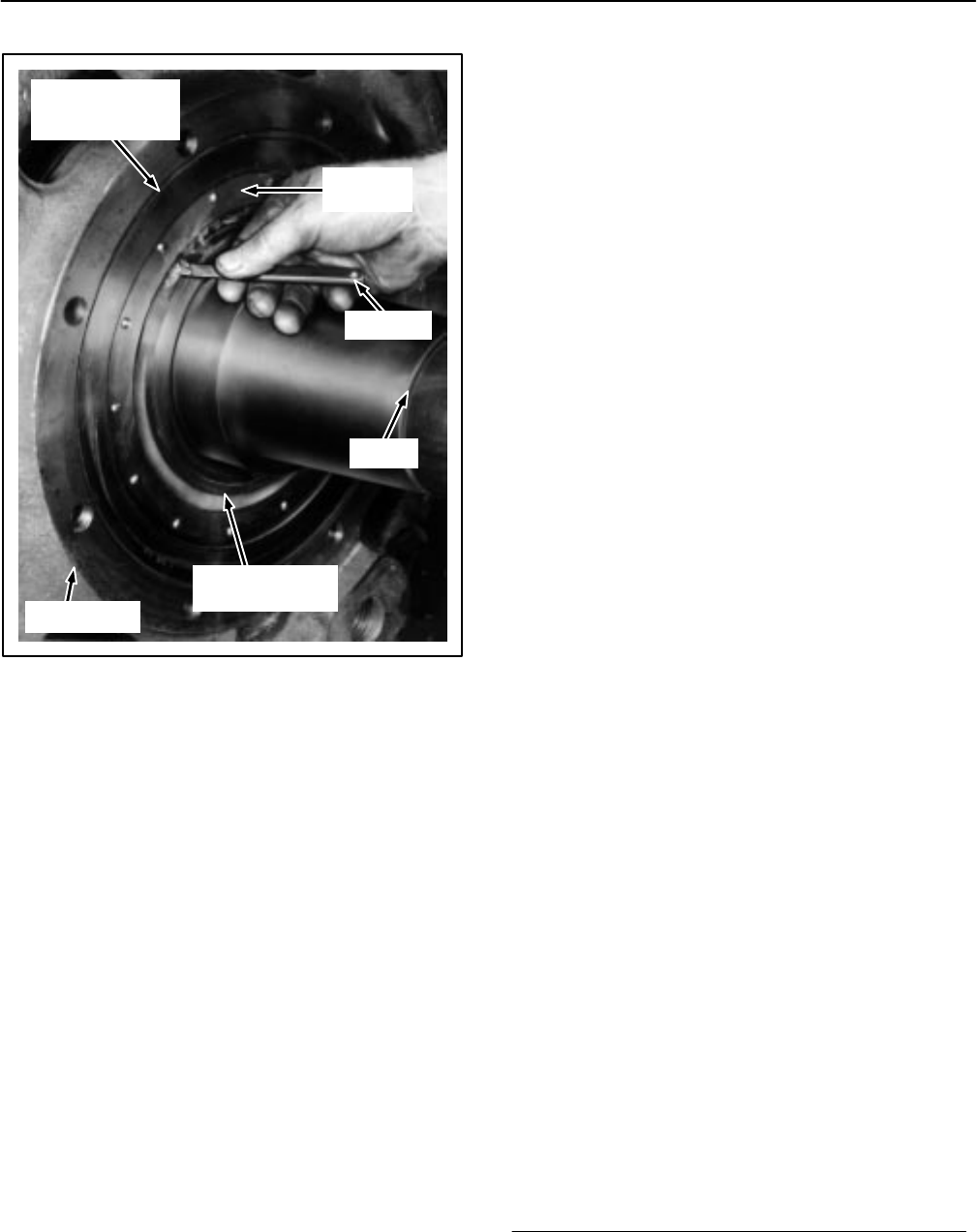

OUTER BEARING

RACE WITH

ROLLERS

BEARING

CAGE

INNER BEARING

RACE

FRAMEHEAD

SHAFT

FEELERS

FIG. 40. CHECKING INTERNAL CLEARANCE OF

BEARING. A-120403.

11. The clearance between the rollers and the inner

race should measure between 0.0012 and 0.004

in. Try various gauge thicknesses until clearance

can be determined by the feel of the gauge as the

gauge is slowly pulled from between the roller

and the inner race.

12. Pack 4.8 oz. of grease in the outer circumference

of outer bearing cap (5).

13. Install a new gasket (54) and bearing cap (5) with

bolts and lockwashers (53).

14. Smear seals on bearing cap (5) and sleeve (47)

with grease.

15. Heat sleeve (47) to 110_ C (230_ F) rise and

shrink it onto the shaft tight against the roller

bearing inner race (48).

16. Seal the grease tubes which protrude through

the hole in the frame with RTV–108.

17. At the commutator end, smear the seals on bear-

ing cap (4) and sleeve (42) with grease.

NOTE: Prior to heating sleeve (42), apply NAL-

CO RC* “Rail Conditioner” to the inside diame-

ter of the sleeve and to the mating surface on

the shaft. Apply the NALCO with a Scott–150

white paper towel only and allow it to dry to a

thin white film on both surfaces before pro-

ceeding with Step 18.

18. Heat sleeve (42) to 180_ C (356_ F) rise and

shrink it onto the shaft tight against the spacer

(43).

19. Assemble the grease tubes to the bearing cap

(4) (UP1 and AUP1 models only). Install pipe

plugs in tubes and tube fittings as indicated in

Fig. 15.

NOTE: Insure that grease tubes are packed full

of grease.

Armature Assembly Into Frame

Models US1, AUT

Refer to Fig. 18.

1. Assemble the brushholders into the frame. Move

them well back from the commutator to avoid in-

terference when installing the armature. Fasten

and insulate the connections and install outgoing

cables.

2. Block and level the frame in a vertical position,

commutator–end down, on a heavy duty stand.

Be sure there is clearance for the commutator–

end shaft extension when the armature is low-

ered into the frame.

3. Install three guide studs in the commutator–end

bearing housing bolt circle to guide the housing

into the framehead fit.

4. Pack 5.25 oz. of grease in the outer circumfer-

ence of bearing cap (8).

5. Lift the armature with the hoist and lifting bail at

the drive end. Line up the hoist directly over the

center of the cavity in the frame.

*Product of NALCO Chemical Co.