Vertical Drilling Motor, Type GE752, GEK–91584D

45

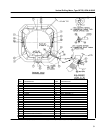

MOTOR FRAME FIELD COIL

REPLACEMENT

Refer to Table 2, Page 20, to determine the correct

coiled frame assembly drawing for the machine being

repaired.

Coil Removal

1. Remove terminal insulation and disconnect coil

leads. Use a gas torch or brazing tongs to sepa-

rate brazed connections. When using brazing

tongs use low voltage and high a–c current to

heat coil connections.

WARNING: Safety glasses and leather gloves

must be worn at all times during brazing oper-

ations to protect personnel from physical

harm.

NOTE: If a gas torch is used, coil insulation

must be protected from heat by a non–flam-

mable heat absorbent.

1. Pack absorbent around the insulation near

the connection and over adjacent coils.

2. Make sure all exposed insulation is covered

with a thick layer of absorbent, then heat and

separate the coil connections.

2. Heat the coiled frame in an oven at 150_ C (302_

F) for four hours to soften the varnish so pole

bolts can be removed.

Remove the pole bolts and the coil–pole assem-

bly from the magnet frame.

3. Mark any shims for reassembly with the corre-

sponding pole when the coil(s) is installed in the

frame.

Coil Installation

Procedure for New Coil–Pole Assembly

NOTE: Install any exciting coils and braze their

connections before installing commutating

coils.

1. Before installing any coil and pole, clean the pole

contact surface on the frame and the pole piece

mounting surface.

2. Install the new pole and coil in the frame with any

shims that were on the damaged coil. Use new

washers under bolt heads. Lubricate the bolt

heads, threads and washers and draw the pole

bolts moderately tight.

3. Refer to Table 2, Page 20, to determine the cor-

rect coiled frame assembly drawings. All coil

connections must be brazed with silver solder,

GE–B20A6. Use two pieces of solder (0.010 x 1

in. x 1 in.) between terminal surfaces and braze

terminals as follows: