Vertical Drilling Motor, Type GE752, GEK–91584D

57

Armature Bearings

NOTE: Parts that will be shrink–fitted should be

heated in an oven and assembled hot. Make

sure shrink–fitted parts are tight against adja-

cent parts after they have cooled.

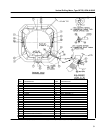

Drive–End Bearing

(Figs. 34, 35, 36 and 37)

1. Place the armature in a saddle.

2. If the inner sleeve was removed, heat it to 110_ C

(230_ F) and shrink it tight on the shaft against

the shoulder.

3. Spread 0.5 oz. of grease onto the seals on the

inner and outer bearing caps and the inner

sleeve.

4. Pack 4.8 oz. of grease in the outer circumference

of the inner bearing cap as shown by the shaded

area in the bearing cap.

5. Install the inner bearing cap on the sleeve.

6. Heat and install the flinger tight against the

sleeve.

7. Heat and install the inner race of the roller bear-

ing tight against the flinger.

8. Install the outer race of the bearing in the

framehead.

9. Fill the roller bearing completely with 29.0 oz. of

grease.

10. Install the gasket onto the inner bearing cap.

11. Install guide pins into the inner bearing cap to

guide the framehead into position.

12. Assemble the framehead/bearing assembly

onto the shaft, over the guide pins until seated

against the bearing cap. Remove the guide pins.

NOTE: Orient the inner bearing cap on UP, AUP,

US and AUT models to facilitate grease tube as-

sembly.

13. Assemble the grease tubes to the inner bearing

cap:

a. On UP1 and AUP1 models, there are two

grease tubes, assembled to the inner bearing

cap and protrude through a hole in the frame.

b. On UP2 and AUP2 models, there is one

grease tube, assembled to the inner bearing

cap and protrudes through a hole in the

frame.

c. On all other models, there is one grease tube

assembled to the inner bearing cap and pro-

trudes through a hole in the framehead.

14. Pack 4.8 oz. of grease in the outer circumference

of the outer bearing cap and install the bearing

cap to the framehead. Secure the assembly with

bolts and lockwashers. Torque to the appropriate

value in Table 3, Page 37.

Commutator–End Bearing

(All Models Except US2, UP6, AUT2 and AUP5)

Refer to Fig. 38.

1. Clean and inspect the bearing and the shaft

bearing fit. Remove nicks and burrs.

2. If sleeve (16) was removed, heat it to 110_ C

(230_ F) and shrink it tight onto the shaft against

the shoulder.

3. Pack 5.25 oz. grease into the outer circumfer-

ence of the cavity of bearing housing (8).

4. Heat bearing housing (8) in an oven to 100_ C

(212_ F). While hot, assemble ball bearing (3)

into the housing firmly against the shoulder at the

bottom of the bearing fit.

5. Fill all voids in the ball bearing completely with

approximately 20.8 oz. of grease, Fig. 38. Smear

0.5 oz. of grease on the bearing housing and the

bearing cap seals.

6. Heat the bearing and housing assembly in an

oven to 100_ C (212_ F). While hot, assemble it

onto the shaft, with the inner race tight against

sleeve (16).