Vertical Drilling Motor, Type GE752, GEK–91584D

21

3

FIG. 13. COMMUTATOR–END BEARING PILOT.

E–18150.

heavy paper around the commutator for protec-

tion during handling.

4. Remove grease tubes from the commutator–

end bearing cap:

a. On UP1 and AUP1 models, there are two

grease tubes (19, 20).

b. On UP2 and AUP2 models, there is one

grease tube (19).

c. On all other models, only a pipe plug is pro-

vided in the bearing cap.

5. Install puller (Part 6751547G4) and pull sleeve

(42) from the shaft at the commutator end. The

sleeve has four tapped holes for applying the

puller. Apply heat to the sleeve with a torch while

pulling to facilitate removal.

6. Remove bolts and washers (52) and remove

bearing cap (4) and gasket (57) from the frame

head.

7. Make sure the armature locking arrangement is

securely installed. Turn the machine on end on a

stand (commutator–end down) and level it so the

armature can be lifted vertically out of the frame

without damaging the bearings, commutator or

brushholders. Remove the armature locking ar-

rangement.

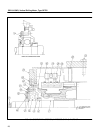

FIG. 14. ARMATURE LIFTING BAIL. E–23932.