GEK–91584D, Vertical Drilling Motor, Type GE752

36

briplate* (Part 147X1614), Molykote** (Part 147X1143),

Dag*** (Part 147X1613), or anti–seize compound (Part

147X1640) to lubricate bolts.

NOTE: Threads and washer–contact surfaces

must be clean before lubricant is applied.

Where specific torque values are not listed in these

instructions, refer to Table 3 for standard bolt torque val-

ues of lubricated bolts.

*Product of Fisk Bros. Refining Co., Newark, N.J.

**Registered trademark of Dow Corning Corp.

***Acheson Colloids Co., Port Huron, Mich.

BRUSHHOLDER SLEEVE REPLACEMENT

1. Remove the damaged Teflon sleeve from the

brushholder stud. To remove sleeve, heat the

brushholder in an oven to 150_ C (302_ F) then

peel or cut sleeve from the stud.

2. Thoroughly clean the surface of the stud and re-

move any carbon or dirt build–up.

3. Heat a new Teflon sleeve in a 150_ C (302_ F)

oven for 15 minutes.

4. Using adequate hand protection, immediately

assemble the hot sleeve on the stud.

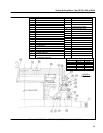

FIG. 21. CONNECTION DIAGRAM (493A210 CHG. 4). E–39092B.

UP1

UP2

UP3

MODELS

SEE TABLE 2

TO CHANGE MOTOR DIRECTION:

TO RUN CCW VIEWED FROM COMMUTATOR END,

CONNECT: F1 TO POSITIVE

F2 TO NEGATIVE

A1 TO POSITIVE

A2 TO NEGATIVE

TO RUN CW VIEWED FROM COMMUTATOR END,

CONNECT: F1 TO NEGATIVE

F2 TO POSITIVE

A1 TO POSITIVE

A2 TO NEGATIVE