INSTALLATION

A-6 A-6

DC-600

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

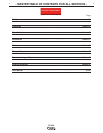

CONNECTION FOR 380 VOLTS, 50 OR 60 HZ.

CONNECTION FOR 440 VOLTS 50 OR 60 HZ. (460V 60HZ)

1. TURN OFF THE INPUT POWER USING THE DISCONNECT SWITCH AT THE FUSE BOX

2. DISCONNECT AND INSULATE THE H2 & H3 LEAD TERMINALS SEPARATELY WITH TAPE TO PROVIDE AT

LEAST 600 VOLT INSULATION.

3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES H1 AND H4 CONTROL TRANSFORMER LEADS TO THE

INPUT SIDE OF THE CRI CONTRACTOR AS SHOWN.

4. CONNECT TERMINAL MARKED TO GROUND PER LOCAL AND NATIONAL ELECTRIC CODES.

5. MOUNT THE LINKS IN THE POSITIONS SHOWN: DOUBLE OR TRIPLE STACK THE LINKS IN THREE

POSITIONS. CONNECT THE FLEX LEAD AS SHOWN: POSITIONING THE LUGS TO MAINTAIN MAXIMUM

CLEARANCE TO THE LINKS. INSTALL AND TIGHTEN ALL OF THE HEX NUTS.

1. TURN OFF THE INPUT POWER USING THE DISCONNECT SWITCH AT THE FUSE BOX

2. DISCONNECT AND INSULATE THE H2 & H4 LEAD TERMINALS SEPARATELY WITH TAPE TO PROVIDE AT

LEAST 600 VOLT INSULATION.

3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES H1 AND H3 CONTROL TRANSFORMER LEADS TO THE

INPUT SIDE OF THE CRI CONTACTOR AS SHOWN.

4. CONNECT TERMINAL MARKED TO GROUND PER LOCAL AND NATIONAL ELECTRIC CODES.

5. MOUNT THE LINKS IN THE POSITIONS SHOWN: DOUBLE UP THE LINKS IN TWO OF THE POSITIONS,

LOOP THE POSITIONS. INSTALL AND TIGHTEN ALL OF THE HEX NUTS.

L3

L2

L1

LINKS

LINES

INPUT

H4

H1

H2

GND

W

V

U

CONTACTOR

CRI

H3

L3

L2

L1

LINKS

LINES

INPUT

H3

H1

H2

GND

W

V

U

CONTACTOR

CRI

H4

L3

L2

L1

LINKS

LINES

INPUT

H2

H1

H3

GND

W

V

U

CONTACTOR

CRI

H4

1. TURN OFFTHE INPUT POWER USING THE DISCONNECT SWITCH AT THE FUSE BOX

2. DISCONNECT AND INSULATE THE H3 & H4 LEAD TERMINALS SEPARATELY WITH TAPE TO PROVIDE AT

LEAST 600 VOLT INSULATION.

3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES H1 AND H2 CONTROL TRANSFORMER LEADS TO THE

INPUT SIDE OF THE CRI CONTACTOR AS SHOWN.

4. CONNECT TERMINAL MARKED TO GROUND PER LOCAL AND NATIONAL ELECTRIC CODES.

5. MOUNT THE LINKS IN THE POSITIONS SHOWN. LOOP THE FLEX LEAD IN THE POSITION SHOWN.

INSTALL AND TIGHTEN ALL OF THE HEX NUTS.

CONNECTION FOR 220 VOLTS, 50 OR 60 HZ.

PILOT

TRANSF.

PILOT

TRANSF.

PILOT

TRANSF.

FIGURE A.5-Reconnect Panel Board Positions for 220/380/440 VAC Machines

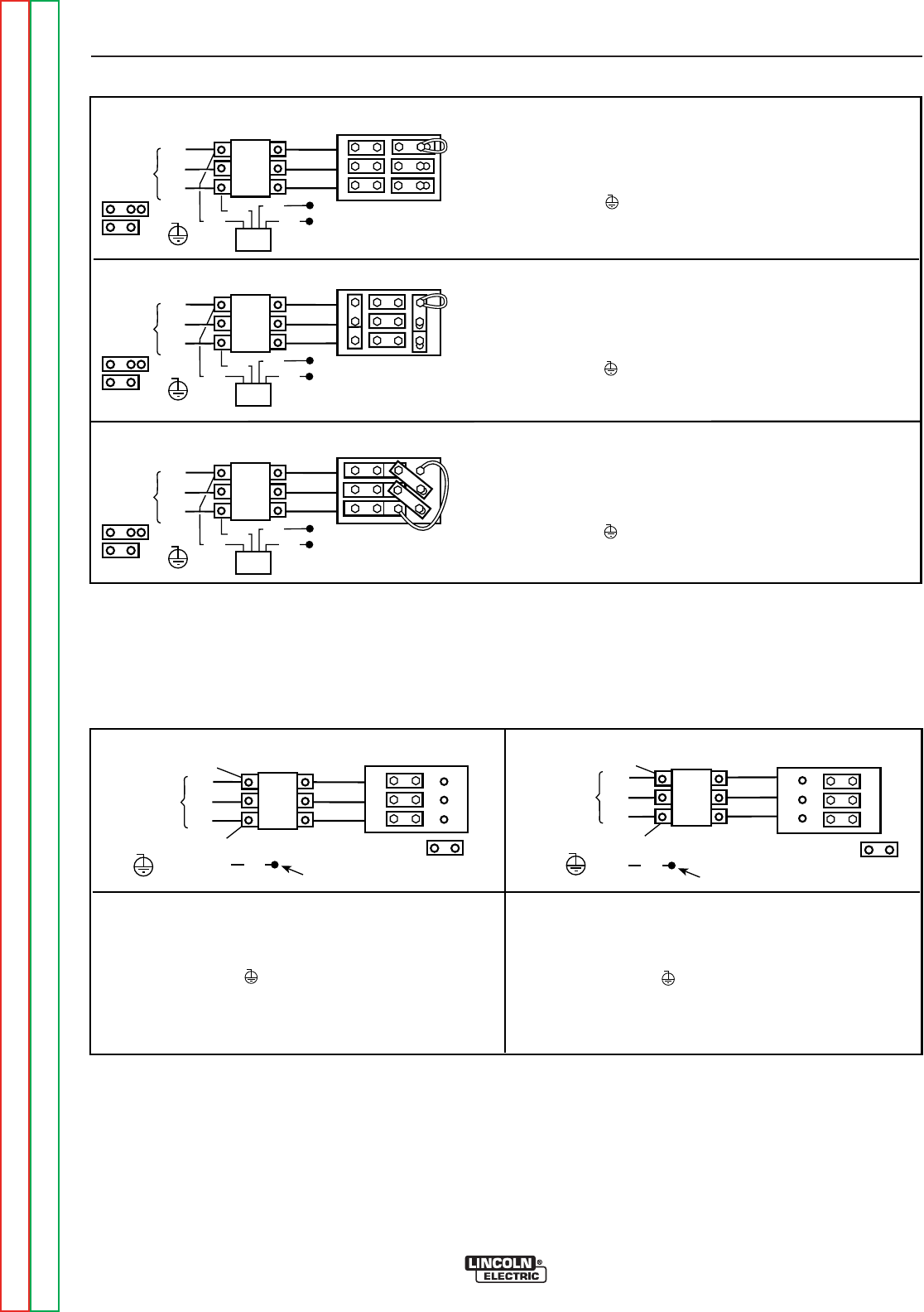

FIGURE A.6-Reconnect Panel Board Positions for 380/500, 460/575 VAC Machines

CONNECTION FOR 380/460 VOLTAGES

1. DISCONNECT AND INSULATE THE H2 LEAD TERMINAL WITH TAPE TO PROVIDE AT

LEAST 600 VOLT INSULATION.

2. CONNECT H3 LEAD TO CONTACTOR..

3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES TO THE INPUT SIDE OF THE CRI CONTACTOR

AS SHOWN.

4. CONNECT TERMINAL MARKED TO GROUND PER NATIONAL ELECTRIC CODES.

5. REMOVE THE HEX NUTS AND POSITION LINKS AS SHOWN, REPLACE AND TIGHTEN

ALL HEX NUTS

L3

L2

L1

LINK

LINES

INPUT

H2

H3

GND

W

V

U

CONTACTOR

CRI

L3

L2

L1

LINK

LINES

INPUT

GND

H2

W

V

U

CRI

CONTACTOR

H1

TAPE

CONNECTION FOR 500/575 VOLTAGES

H3

H1

1. DISCONNECT AND INSULATE THE H3 LEAD TERMINA WITH TAPE TO PROVIDE AT

LEAST 600 VOLT INSULATION.

2. CONNECT H2 LEAD TO CONTACTOR.

3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES TO THE INPUT SIDE OF THE CRI CONTACTOR

AS SHOWN.

4. CONNECT TERMINAL MARKED TO GROUND PER NATIONAL ELECTRIC CODES.

5. REMOVE THE HEX NUTS AND POSITION LINKS AS SHOWN. REPLACE AND TIGHTEN

ALL HEX NUTS

TAPE