THEORY OF OPERATION

E-3 E-3

DC-600

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

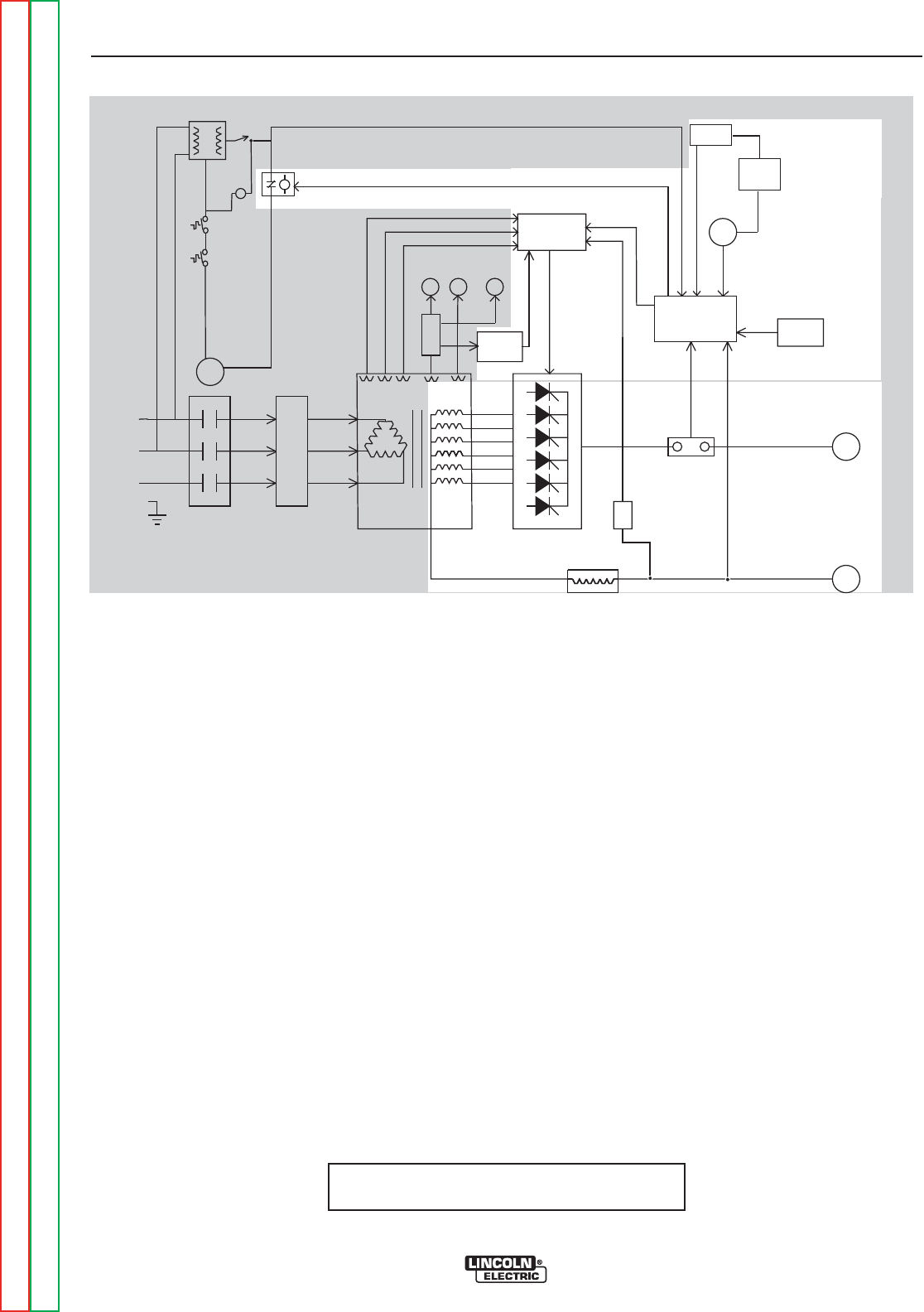

FIRING CIRCUIT, CONTROL CIR-

CUIT AND RECTIFICATION

RECTIFICATION

The “neutrals” of the welding secondary windings in the

main transformer are connected together, and the six

starts are connected to the six Silicon Controlled

Rectifier (SCR) assemblies to form a six-phase output.

This six-phase AC output from the main transformer

secondary is rectified and controlled by the SCR

bridge.

FIRING BOARD

The firing board is powered by the three-phase 32vac

transformer windings. Each phase provides two firing

pulses, one for each of the two SCRs controlled by that

phase. When a gate firing enable*(trigger) signal is

received, the firing circuit supplies the proper amount

of energy to the gates of the power SCRs. When this

gate firing signal is applied at the correct time, the SCR

will turn ON. The amount of ON time versus OFF time

determines the output of the machine. See SCR

Operation. At the same time the latching resistor is

connected across the machine’s output circuit. The

latching resistor provides a pre-load for the SCR bridge

so the SCR’s will stay activated providing open circuit

voltage (OCV).

FIGURE E.2 - FIRING BOARD,CONTROL BOARD AND RECTIFICATION

CONTROL BOARD

The control board receives current feedback informa-

tion from the shunt and voltage feedback information

from the choke and welding output terminals. This

feedback information is processed on the control

board. The control board compares the commands of

the mode switch, the output control potentiometer (or

remote control device) and the arc force control with

the feedback information and sends the appropriate

output control signal to the firing board. In the event of

a “fault condition,” the control board de-activates the

fault relay (CR2). See Protective Devices and Shut

Down Circuits.

An output choke is connected between the neutral con-

nection of the main transformer secondaries and the

negative output terminal. This large inductor stores

energy, and provides current filtering for the welding

output of the DC-600.

*Triggering is accomplished by a connection of lead

#2 & #4 by way of the Output Terminal Switch or by a

remote signal from a wire feeder. The 2 to 4 closure

is indicated by LED10 on the firing Board and LED 6

on the Control Board.

CONTROL

TRANSFORMER

R

E

C

O

N

N

E

C

T

CONTACTOR

FAULTPROTECTION

115VAC

MAIN

TRANSFORMER

CONTROL

BOARD

SHUNT

OUTPUT

CONTROL

MODE

SWITCH

POSITIVE

TERMINAL

NEGATIVE

TERMINAL

LATCHING

RESISTOR

F

E

E

D

B

A

C

K

F

E

E

D

B

A

C

K

SCR BRIDGE

115VAC

42VAC

T

E

R

M

I

N

A

L

S

T

R

I

P

FIRING

BOARD

CR2

CR1

CHOKE

14-pin

Amphenol

115VAC

Receptacle

Fan

Motor

32VAC

32VAC

32VAC

SIGNAL

G

A

T

E

S

I

G

N

A

L

OUTPUT

CONTROL

Secondary

Thermostat

Primary

Theromstat

1CRCoil

w

Pilot

Light

•

•

OUTPUT

TERMINAL

SWITCH

POWER

SWITCH

•

TERMINAL

STRIP 1

OUTPUT

CONTROL

SWITCH

2

115VAC

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion