OPERATION

B-5 B-5

DC-600

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CONTROLS AND SETTINGS

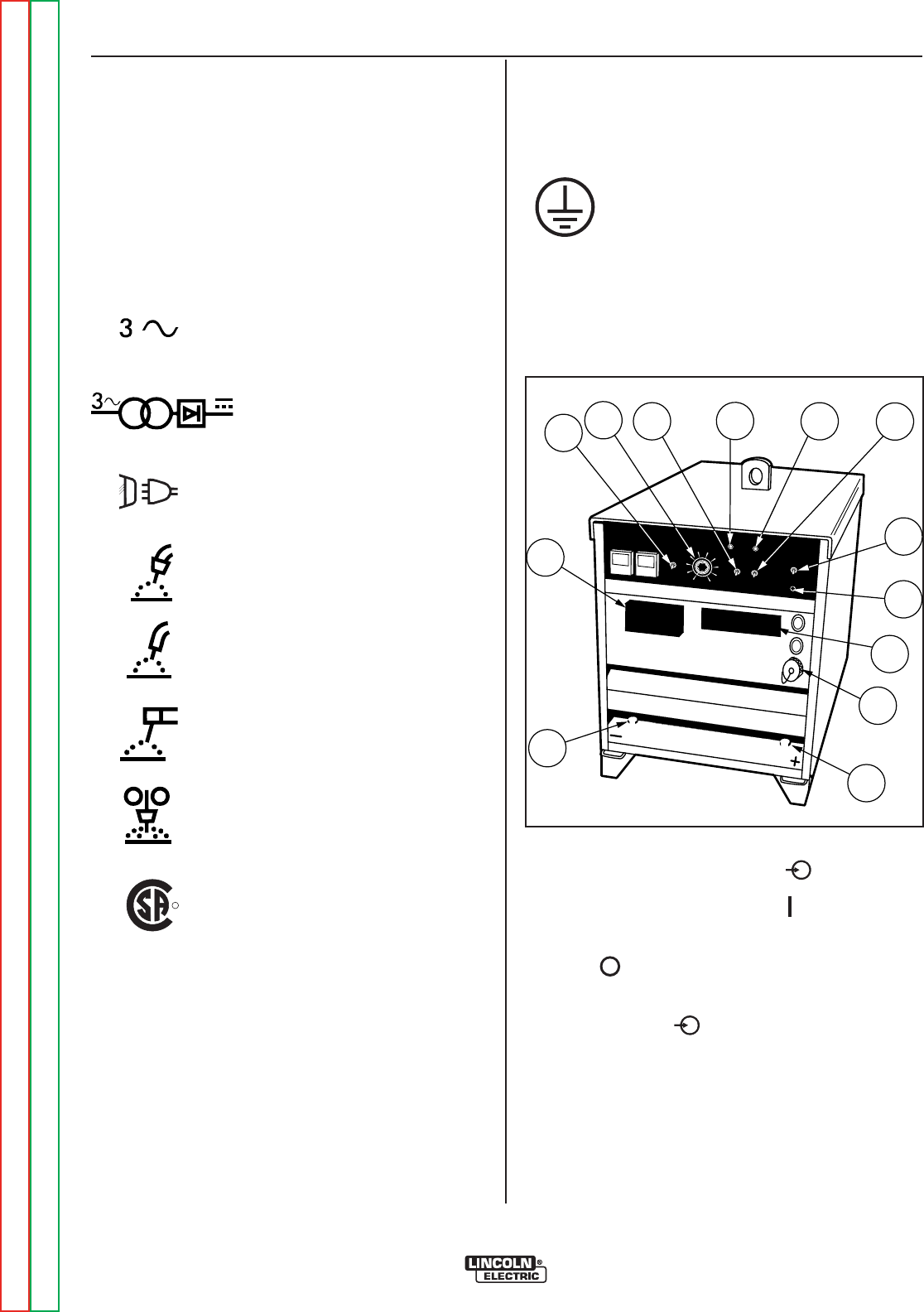

All operator controls and adjustments are located on

the Case Front Assembly of the DC-600. See Figure

B.1 for the location of each control.

FIGURE B.1 - CONTROL PANEL KEYS

1

2

3

4

5

6

7

8

9

10

DC-600

13

12

7

5

11

2

1

49

8

6

3

10

3 Phase transformer with recti-

fied DC output

Line Connection

Three Phase Input Power

Designates welder complies with

National Electrical Manufacturers

Association requirements EW 1

Class I with 100% duty cycle at

600Amps output.

Designates welder complies with

both Underwriters Laboratories (UL)

standards and Canadian Standards

Association (CSA) standards. (60

Hertz Models)

Gas Metal Arc Welding (GMAW)

Flux Cored Arc Welding (FCAW)

MEANING OF GRAPHICAL

SYMBOLS ON RATING PLATE

(LOCATED ON CASE BACK)

NEMA EW 1 (100%)

Shielded Metal Arc Welding (SMAW)

Submerged Arc Welding (SAW)

MEANING OF GRAPHICAL

SYMBOL FOR GROUND CON-

NECTION

Signifies the equipment connection

point for the protective earth ground

R

NRTL/C

1. Input POWER ON/OFF Switch

This toggle switch turns the machine on or off.

Putting the switch in the ON “ ” position ener-

gizes the machine’s input contactor applying input

power to the machine. Switching the switch to the

OFF “ ” position de-energizes the input con-

tactor.

2. POWER Light

When the POWER switch is in the ON position the

machine’s white POWER light will illuminate. If the

input contactor de-energizes the machine in an

abnormal situation the pilot light will still illuminate.

In this situation it may be necessary to reset the

machine by switching the POWER switch to the

OFF and then to the ON position. (See Overload,

Overcurrent, and Fault Protection Section)